Today in our country, as in all over the world, fire occurs in our living areas due to the preventable or inevitable factors. Due to the rapid population increase, irregular urbanization and rapid industrialization factors in our country, the number of fires and financial losses caused by fires increase day by day.

It is a clear fact that a spark can destroy all our efforts and hopes in minutes. Many countries have developed various guidelines for fire protection. According to these guidelines, the materials used in our constructions must be fire resistant [1].

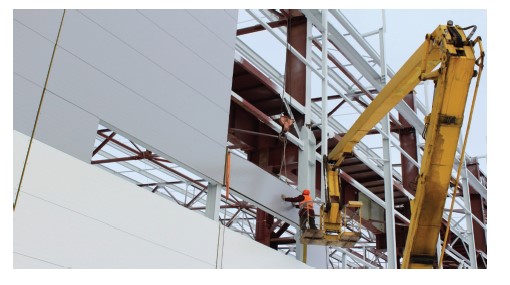

The use of traditional materials in today’s architectural structures are abandoned due to economic reasons and difficulties encountered during the construction phase. For these reasons, sandwich panels are used as building material; because they are easy to use and economical.

In general terms, sandwich panels are building materials that provide thermal insulation and mechanical strength between aluminum or galvanized sheets containing different type and thickness filling material.

In sandwich panels, polyurethane foam (PUR), polyisocyanurate foam (PIR), expanded polystyrene foam (EPS), extruded polystyrene rigid foam (XPS), rock wool and glass wool are generally used as internal filling materials [2].

Figure 1. Sandwich panel systems as building materials

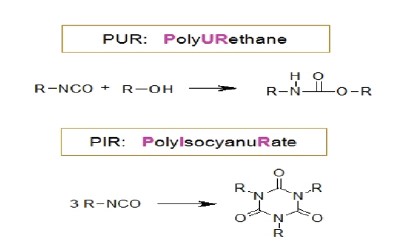

Polyurethane foams are chemically, or physically foamed copolymers formed by diisocyanates containing two or more -NCO groups and diols containing two or more groups of -OH interconnected with urethane groups [3,4].

Polyisocyanurate foams (PIRs) are shown as building materials based on fire of the future with their low thermal conductivity, high compression strength and high dimensional stability. Polyisocyanurate foams is a more specific type of polyurethane foams.

Figure 2. Chemical representation of polyurethane foam and polyurethane foam structures

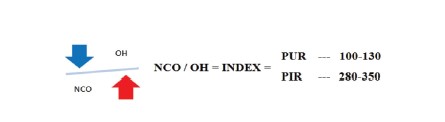

The difference between polyurethane foam (PUR) and polyisocyanurate foam (PIR) is that the diisocyanate and diols are stochiometric at different rates during the phases of foam formation reactions.

While the ratio of polyurethane foams (NCO/OH) is close to 1 or slightly above 1, the ratio of polyisocyanurate foams (PIRs ) is larger than the ratio of polyurethane foams and closer to 2. In short, in polyisocyanurate foams, there are diisocyanate molecules in the environment more than the amount that will react completely with diols.

The excess amount of -NCO groups in the environment react with the various trimerization catalysts to form isocyanate structures. The isocyanate blocks in the ring structure improve the non-flammability properties of the foam structure [5,6,7].

Figure 3. Index ratios of polyurethane foam (PUR) and polyisocyanurate foam (PIR)

Generally, the polyisocyanurate foam formulation includes polyester polyol mixtures (-OH component), polymeric MDI (-NCO component), additives, trimerization catalysis mixtures and blowing agents. Good non-flammability properties of polyisocyanurate foams depend on polyester polyol structures in isocyanate and aromatic form.

Figure 4. Polyisocyanurate foam (PIR) panel systems

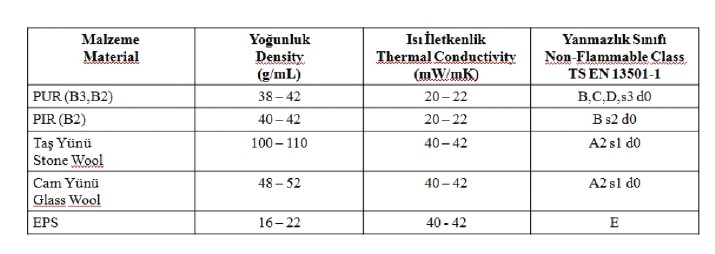

Table 1. Fire classes, densities and thermal conductivity coefficient values of insulating materials used in sandwich panels

As the Kimteks polyurethane family, we are increase our R&D activities day by day for the preparation of innovative, economical and environmentally friendly products. As the products of our company, KimRIGID PIR systems offers excellent solutions for sandwich panel manufacturers.

KimRIGID PIR systems are more efficient structures that provide higher fire resistance than PUR systems. Thanks to the isocyanate structures, the resistance of the foam to the flame increases during the fire.

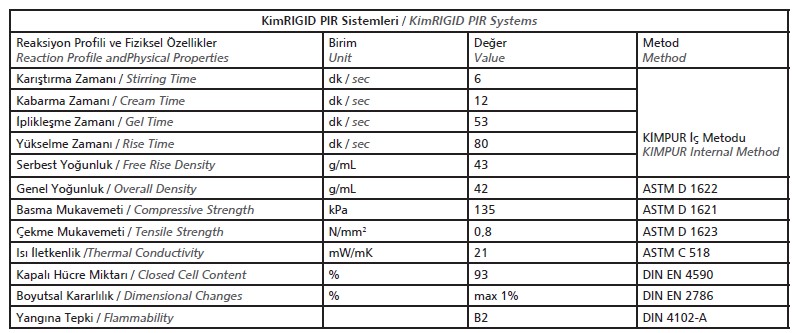

KimRIGID PIR systems are products which have a compression strength of 130-150 kPa, with density of 38-42 g/ml, having a 21 mW/mK thermal conductivity coefficient and a minimum resistance of burning B s2 d0 according to the European standard SBI (Single Burning Item).

Table 2. Reaction profile analysis and physical characterization of foams of Kimteks Polyurethane KIMrigid PIR systems

Dr. Emre Baştürk

R&D Responsible

Rigid Systems

Kimteks Poliüretan San. ve Tic. A.Ş.