Usages of metallic materials in many different applications are very common in the industry. Recent researches show that industrialized countries spend 2-5% of their annual budgets for the protection of metals.

Long-term durability and conservation of the main properties of the metals are very important. Harsh environmental conditions affect the material and microcracks can easily begin. Therefore, the protection of the metal surfaces with polymeric coatings and prolonging the life of the coating materials are very important.

The presence of local defects or micro-cracks in the polymeric coatings results fatal damages to metals by initiation of corrosion. In order to make the polymeric coatings more durable several approaches of self-healing mechanism have been suggested.

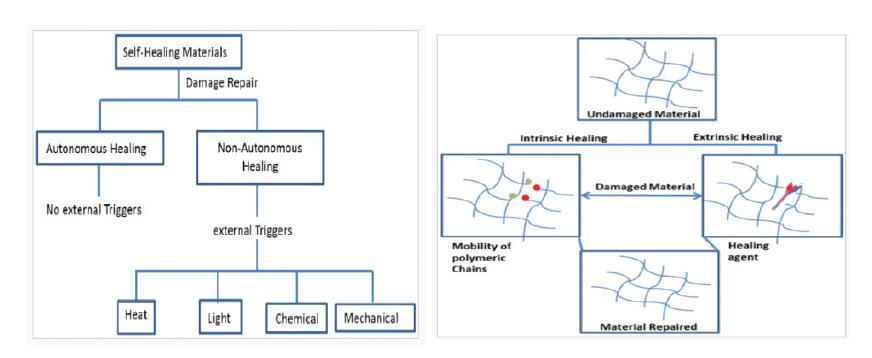

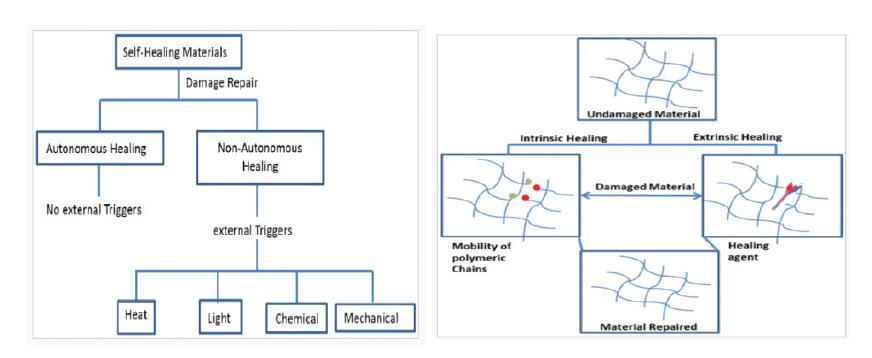

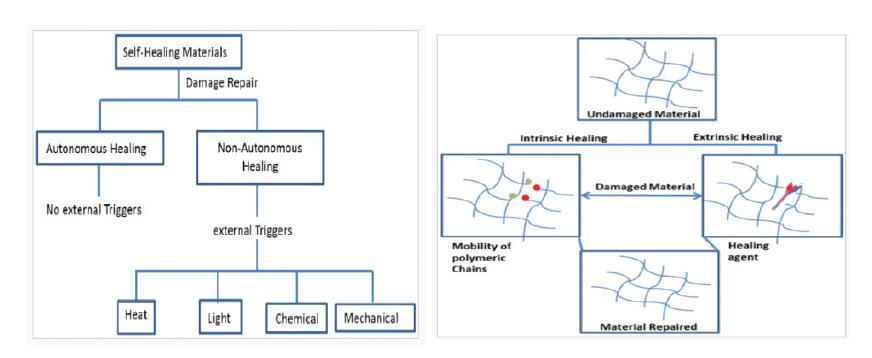

It can be divided into two large categories; intrinsic and extrinsic self-healing mechanism. In the extrinsic (Autonomous) mechanism smart self-healing microspheres are incorporated into the protective polymeric matrix.

It is broken and releases the healing substances from microcapsules when a crack is occurred. In the intrinsic (Non-Autonomous) self-healing mechanism dynamic reversible ionic and/or covalent bonds take action in the polymeric network that they act like a binder after a crack occurs in the polymeric network.

A physical action may be needed such as heating, mechanical force, ultraviolet (UV) or pH adjustments, in order to initiate the self-healing ability of the functional groups in the polymeric coatings. [1-3]

Figure 1.

Figure 1. Illustrate the difference between autonomic and non-autonomic self-repairing process

Paints and varnishes, especially used in coatings applied for the protection of metals in bridges, pipelines, plane fuselages, cars etc., with self-healing properties take great attention because of the economic benefits by providing durability to the metals by inhibiting metal corrosion.

Especially epoxy-amine curing systems with self-healing properties have great attention by the researchers because of its specific chemical structures and various design flexibilities as compared to the silicones, thermosetting polymers, rubbers and hydrogels. They are generally used as coating materials for anticorrosion in marine industry. [4-6]

Figure 2

Figure 2. Plausible curing reaction of (a) Alkyd and epoxide group to form ester bond and (b) Alkyd and amine hardener to formamide bond

By incorporating chemicals with reactive functional groups especially alkyd derivatives into the epoxyamine curing systems, self-healing blends may be obtained. By heating the cracked area, the carboxylic acid groups of alkyds react with unopened epoxy groups and also with hydroxyl groups.

Also, acid groups may react with amine groups. Plausible reaction mechanism was suggested by researchers.[6] Izel Chemical Company makes researches on the production of novel bio-based materials with self-healing properties in order to make metals protected from corrosion.

Especially various oil derivatives are good candidates to be modified to show self-healing properties.

Referanslar

1) Mphahlele, Keletso&Sinha Ray, Suprakas&Kolesnikov, Andrei. (2017). Self-Healing Polymeric Composite Material Design, Failure Analysis and Future Outlook: A Review. Polymers.

2) Wang, Rongguo&Hu, Honglin&Liu, Wenbo&Guo, Qiong. (2011). Preparation and Characterization of Selfhealing Polymeric Materials with Microencapsulated Epoxy and Imidazoline Derivatives Curing Agent. Polymers and Polymer Composites.

3) Yu, Kunhao&Xin, An&Du, Haixu&Li, Ying&Wang, Qiming. (2019). Additive manufacturing of self-healing elastomers. NPG Asia Materials.

4) Post, W. (2017). Self-Healing Polymer Composites.

5) Madara, Sahith Reddy et al. “Review of research and developments in self healing composite materials.” (2018).

6) Shahabudin, N., Yahya, R., Gan, S. N&Sonsudin, F. (2018). Curing of epoxy/alkyd blends in self-healing coating. High Performance Polymers, 30(8), 1009–1015.

Figure 1. Illustrate the difference between autonomic and non-autonomic self-repairing process

Paints and varnishes, especially used in coatings applied for the protection of metals in bridges, pipelines, plane fuselages, cars etc., with self-healing properties take great attention because of the economic benefits by providing durability to the metals by inhibiting metal corrosion.

Especially epoxy-amine curing systems with self-healing properties have great attention by the researchers because of its specific chemical structures and various design flexibilities as compared to the silicones, thermosetting polymers, rubbers and hydrogels. They are generally used as coating materials for anticorrosion in marine industry. [4-6]

Figure 1. Illustrate the difference between autonomic and non-autonomic self-repairing process

Paints and varnishes, especially used in coatings applied for the protection of metals in bridges, pipelines, plane fuselages, cars etc., with self-healing properties take great attention because of the economic benefits by providing durability to the metals by inhibiting metal corrosion.

Especially epoxy-amine curing systems with self-healing properties have great attention by the researchers because of its specific chemical structures and various design flexibilities as compared to the silicones, thermosetting polymers, rubbers and hydrogels. They are generally used as coating materials for anticorrosion in marine industry. [4-6]

Figure 2. Plausible curing reaction of (a) Alkyd and epoxide group to form ester bond and (b) Alkyd and amine hardener to formamide bond

By incorporating chemicals with reactive functional groups especially alkyd derivatives into the epoxyamine curing systems, self-healing blends may be obtained. By heating the cracked area, the carboxylic acid groups of alkyds react with unopened epoxy groups and also with hydroxyl groups.

Also, acid groups may react with amine groups. Plausible reaction mechanism was suggested by researchers.[6] Izel Chemical Company makes researches on the production of novel bio-based materials with self-healing properties in order to make metals protected from corrosion.

Especially various oil derivatives are good candidates to be modified to show self-healing properties.

Figure 2. Plausible curing reaction of (a) Alkyd and epoxide group to form ester bond and (b) Alkyd and amine hardener to formamide bond

By incorporating chemicals with reactive functional groups especially alkyd derivatives into the epoxyamine curing systems, self-healing blends may be obtained. By heating the cracked area, the carboxylic acid groups of alkyds react with unopened epoxy groups and also with hydroxyl groups.

Also, acid groups may react with amine groups. Plausible reaction mechanism was suggested by researchers.[6] Izel Chemical Company makes researches on the production of novel bio-based materials with self-healing properties in order to make metals protected from corrosion.

Especially various oil derivatives are good candidates to be modified to show self-healing properties.