Commercial polyurethane building blocks and products are attractive alternatives to many thermoplastic and thermoset material because of their efficacy and their efficiency. The coating industry is one of the important market for polyurethane-based applications. The American Society for Testing and Materials classifies polyurethane coatings based on their characteristics and method of cure and their predominant application areas

1. They can be cured as one part (1K) or two part (2K) curing mechanism with their reactive or non reactive side. They can be in powder form, solvent based or waterborne. They can be cured by technology of the radiation curing mechanism even if they are solvent-based or waterborne.

Polyurethane coatings have generous applications and possess the following properties that vary from other technologies: resistance to abrasion, film flexibility, gloss finish, chemical resistance and good number of features could be written. Waterborne applications are more

attractive among the others because of low or / and non-VOC (Volatile Organic Compounds) contents. Global consumption of polyurethane coating is still dominantly solvent-based

2. Replacement of waterbased solutions are expected to be increased. Environmental regulations on the emissions control of volatile organic compounds (VOCs)

3 seems to be a driving force for developing these high-performance waterborne polymers.

Figure-1 shows that from the beginning of 2000s PUDs and relevant publications has raised and now its in top. Therefore this figure confirms the market research

4, the industry of PUDs makes a growth at Asian countries.

[caption id="attachment_137029" align="aligncenter" width="1258"]

Figure 1.

Figure 1. Patent Statistics of European Patent Office, February 22[/caption]

Commercially available aqueous polyurethane dispersions (PUDs) were introduced to the market in 1950s. The industry had to wait for the fully solvent-free products until the beginning of 2000s

5. The specificity of isocyanate reactivity with active hydrogen atoms,

results in enormous potential for polymer innovation.

The aqueous polyurethane characteristics are resulting from the chemical structure of urethane and urea groups, whose main feature is the formation of multiple hydrogen bonds between adjacent polymer chains and, as a result, the hard segments containing urethane

and urea groups in the dry film by self-assembly into strongly hydrogen-bonded areas connected via the flexible soft segments. This hydrogen bond formation gives the linear polymer its excellent properties at already low molar mass. PUDs have the unique advantage that the viscosity of the dispersion is not dependent on the molecular weight of the polymer neither other water-based polymer alternatives nor solventbased polyurethanes.

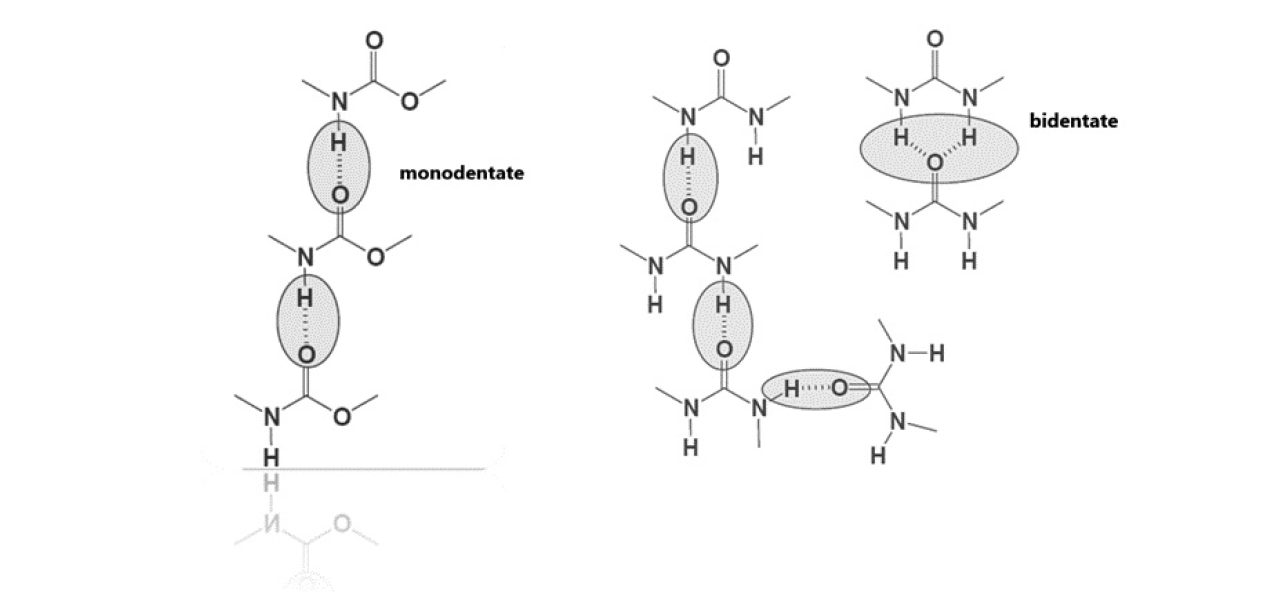

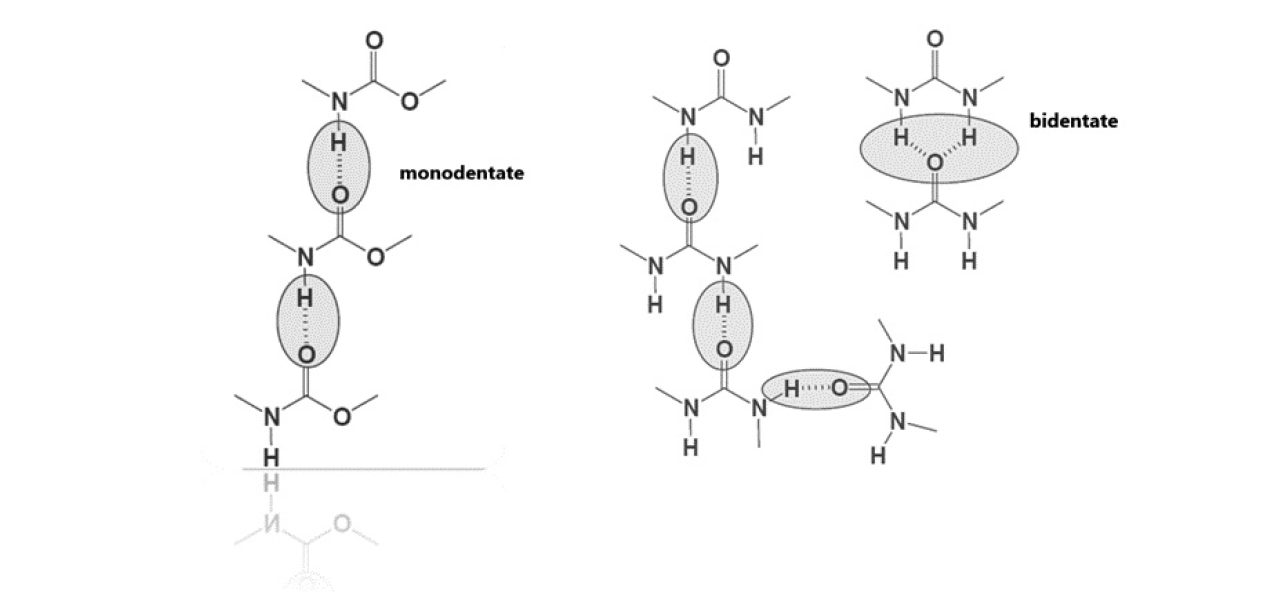

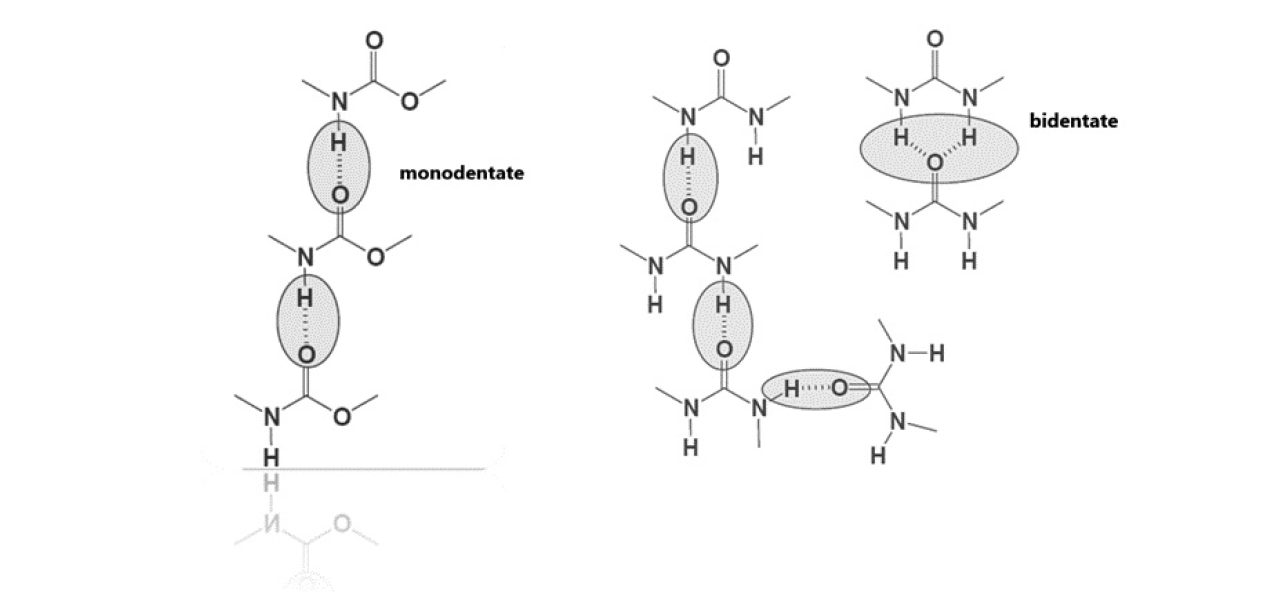

[caption id="attachment_137030" align="aligncenter" width="1273"]

Figure 2.

Figure 2. Monodentate urethane and bidentate urea H-bonding[/caption]

These segments are usually thermodynamically incompatible, leading to phase separation, and thus to a microdomain structure which, depending on the chemical composition, can give rise to materials with a broad range of properties and applications

6. Application list grows that women mascaras, hair conditioners, parquet varnishes, denim coatings, sport-wears, work-safety cloths, dispersing additives for coating formulations, bonding agents, self-healing binders, etc.

7. PUDs can be used as adhesives, coating materials, co-binders, sizing agents and UV-curable binders

8.

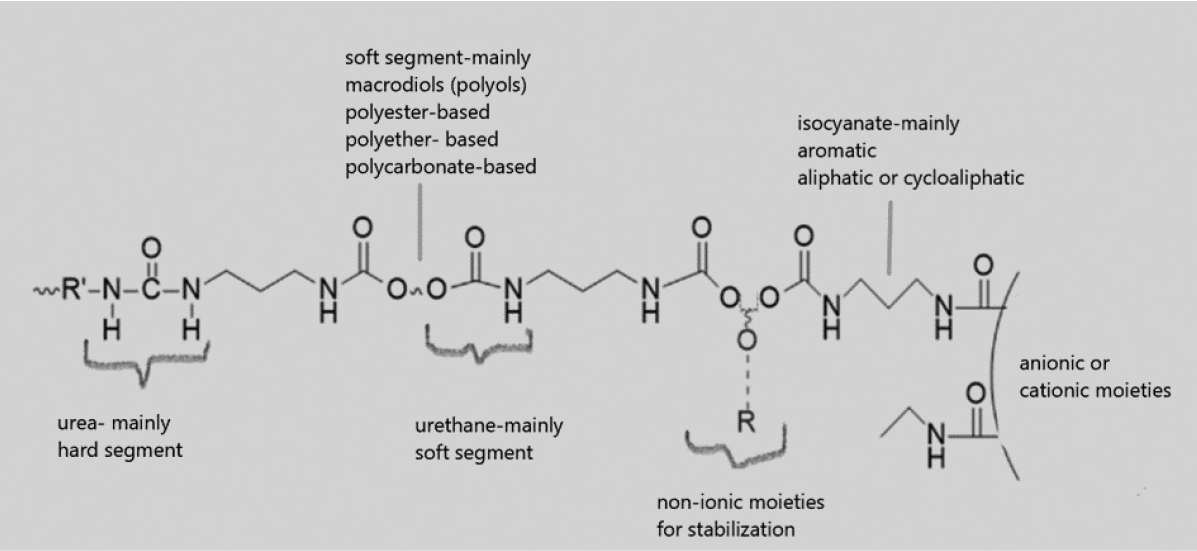

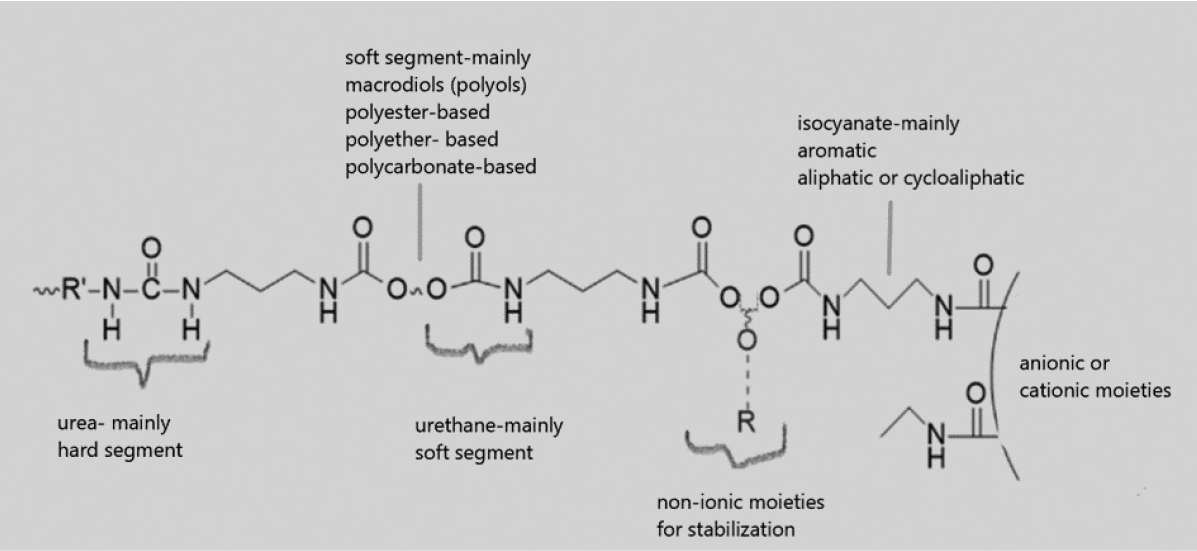

In a typical PUD synthesis, an isocyanate (NCO) terminated pre-polymer is first synthesized by stepgrowth polymerization that contains a stabilizing hydrophilic moiety, and an excess of diisocyanate (NCO / OH >1) in a solvent such as acetone or methyl ethyl ketone. Following this, the PU prepolymer is dispersed in water to form spontaneously self assembled micelle-like structures. The dispersed prepolymer is then chain extended using a diamine to give a high molecular weight polymer and the solvent removed. This self assembled micelle-like dispersed product is emulsifed by internally so this gives the dispersed product sensitivity against to temperature changes.

[caption id="attachment_137031" align="aligncenter" width="1197"]

Figure 3.

Figure 3. Schematic for main ingredients of PUDs (polyurethane-urea dispersions) structure[/caption]

Unique chemistry of PUDs provide UV resistance, abrasion resistance, scratch resistance, moisture management, hydrophobicity-hydrophility, gloss control, tensile strentgh, peelable, wash resistance, impact resistance, adhesion strenth, the list goes on. Because of that, they have a widespread literature coverage.

Distruptive studies based on polyurethane dispersion for Fluorine-free water-proofing agent is still on demand

9. It is not new but it still hot topic that the use of elements like phosphorous, sulfur, silicon; chemical and physical modifications enhance the thermal and mechanical properties of PUDs

10. Based on a recent works, polyurethane (PU) / acrylic hybrid dispersions are an important class of polymeric dispersions that are produced on an industrial scale. It helps to that the products require much fewer film-forming agents for flooring and furniture coating

11.

Using less isocyanate or none-isocyanate applications have been one of the important challenges of the industry for last two decades. New ways for the synthesis of PUDs having less or none-isocyanate is going to be more important in the future. There are lots of EU-funded projects that accept the challenge of the industry and try to combine these problems and give a ‘hybrid’ solution as a technology offering. Polyhydroxyurethanes (PHU) are the most promising polymers that helps using less isocyanate in the polymer backbone but it needs to be more challange to be waterborne dispersion. V. Besse et al summarizes that how PHU’s have low molecular weights

12. This explains that why polyurethanes could not be fully PHU’s based now.

Furthermore, reputable companies who are the pioneers of urethane industry acquires the start-ups to use renewable feedstocks for greener polyurethane industry. The functions of wood coatings, the functions of technical textile coating, the binders for recycled composite material are emerging trends for the national economy, especially for EU harmonization

studies.

In 2050, European based chemical industry will use and produce more carbonized (CO2 based) products. A project, received funding from the European Union and aimed at researching and developing a new technology that can transform CO2 and carbon

monoxide (CO) into polyols

13. In the literature, there is a work on synthesized product of waterborne polyurethane dispersions (WPUDs) from upcycled polyols in foam production demonstrated suitable viability of polyurethane products synthesized from virgin polyol

14.

To conclude, the versatility in composition, properties, processing and applicability of PUDs make them promising materials that may evolve to new fields needing novel and specific requirements.

References

1. Alrashed M., 2013. “Polyurethane / Polysiloxane Ceramer Nanocomposite Coating for. Aircraft Applications” Thesis Advisor: Dr. Sadhan Jana. Rostyslav Dolog, Ph.D.

2. Mark F. Sonnenschein, 2020. Polyurethanes: Science, Technology, Markets, and Trends, 2

nd Edition, | Hoboken : Wiley, 2021. | Series: Wiley series on polymer engineering and technology

3. Ground Level Ozone Pollution, Volatile Organic Compound, United States Environmental Protection Agency (EPA) website

4. Global Overview of PUDs, Coating Industry-EMEA, IAL Consultants Market Report-2021

5. Bayer Materials Science, Coating 2013 Press Release

6. Erol Yildirim, Mine Yurtsever, Emel Yilgör, Iskender Yilgör,Garth L. Wilkes. Temperature-dependent changes in the hydrogen bonded hard segment network and microphase morphology in a model polyurethane: Experimental and simulation studies. Journal of Polymer Science Part B: Polymer Physics 2018, 56 (2) , 182-192.

7. Berezkin, Y., P.D. Schmitt, and S. Unal, Polyurethane dispersions for use in personal care products, 2008, Bayer Materialscience LLC, USA . p. 13pp

8. US9862824B2 ,Carbon fiber sizing agent, aqueous dispersion thereof, carbon fiber bundle applied with sizing agent, sheet-like article comprising carbon fiber bundle, and carbon fiber reinforced composite material

9. CN103628324A, Fluorine-free water-proofing agent and preparation

method thereof as well as textile

10. Swapnil M. Vaidya, et al., Recent developments in waterborne polyurethane dispersions (WPUDs): a mini‑review on thermal and mechanical properties improvement, 2021,Springer Nature

11. Samane Mehravar, Nicholas Ballard, Radmila Tomovska, and José M. Asua, 2019. Polyurethane(PU) / acrylic hybrid waterborne dispersions: Synthesis, properties and applications Ind. Eng. Chem. Res.,

12. V. Besse et al, How to explain low molar masses in PolyHydroxyUrethanes (PHUs), European Polymer Journal 71 (2015) 1-11

13. Carbon4PUR Press Release

14. Iyer D., Srivastava S., ‘Upcycled Polyurethane Products Based Waterborne Polyurethane Dispersions’,Mattress Recycling Council Dispersion Report,2020

Derya Şara

Chemistry Depertmant

Graduate School

Istanbul Technical University

Assist. Prof. Dr. Serkan Ünal

Integrated Manufacturing Tecnologies Research and Application Center

Sabancı University

Figure 1. Patent Statistics of European Patent Office, February 22[/caption]

Commercially available aqueous polyurethane dispersions (PUDs) were introduced to the market in 1950s. The industry had to wait for the fully solvent-free products until the beginning of 2000s5. The specificity of isocyanate reactivity with active hydrogen atoms,

results in enormous potential for polymer innovation.

The aqueous polyurethane characteristics are resulting from the chemical structure of urethane and urea groups, whose main feature is the formation of multiple hydrogen bonds between adjacent polymer chains and, as a result, the hard segments containing urethane

and urea groups in the dry film by self-assembly into strongly hydrogen-bonded areas connected via the flexible soft segments. This hydrogen bond formation gives the linear polymer its excellent properties at already low molar mass. PUDs have the unique advantage that the viscosity of the dispersion is not dependent on the molecular weight of the polymer neither other water-based polymer alternatives nor solventbased polyurethanes.

[caption id="attachment_137030" align="aligncenter" width="1273"]

Figure 1. Patent Statistics of European Patent Office, February 22[/caption]

Commercially available aqueous polyurethane dispersions (PUDs) were introduced to the market in 1950s. The industry had to wait for the fully solvent-free products until the beginning of 2000s5. The specificity of isocyanate reactivity with active hydrogen atoms,

results in enormous potential for polymer innovation.

The aqueous polyurethane characteristics are resulting from the chemical structure of urethane and urea groups, whose main feature is the formation of multiple hydrogen bonds between adjacent polymer chains and, as a result, the hard segments containing urethane

and urea groups in the dry film by self-assembly into strongly hydrogen-bonded areas connected via the flexible soft segments. This hydrogen bond formation gives the linear polymer its excellent properties at already low molar mass. PUDs have the unique advantage that the viscosity of the dispersion is not dependent on the molecular weight of the polymer neither other water-based polymer alternatives nor solventbased polyurethanes.

[caption id="attachment_137030" align="aligncenter" width="1273"] Figure 2. Monodentate urethane and bidentate urea H-bonding[/caption]

These segments are usually thermodynamically incompatible, leading to phase separation, and thus to a microdomain structure which, depending on the chemical composition, can give rise to materials with a broad range of properties and applications6. Application list grows that women mascaras, hair conditioners, parquet varnishes, denim coatings, sport-wears, work-safety cloths, dispersing additives for coating formulations, bonding agents, self-healing binders, etc.7. PUDs can be used as adhesives, coating materials, co-binders, sizing agents and UV-curable binders8.

In a typical PUD synthesis, an isocyanate (NCO) terminated pre-polymer is first synthesized by stepgrowth polymerization that contains a stabilizing hydrophilic moiety, and an excess of diisocyanate (NCO / OH >1) in a solvent such as acetone or methyl ethyl ketone. Following this, the PU prepolymer is dispersed in water to form spontaneously self assembled micelle-like structures. The dispersed prepolymer is then chain extended using a diamine to give a high molecular weight polymer and the solvent removed. This self assembled micelle-like dispersed product is emulsifed by internally so this gives the dispersed product sensitivity against to temperature changes.

[caption id="attachment_137031" align="aligncenter" width="1197"]

Figure 2. Monodentate urethane and bidentate urea H-bonding[/caption]

These segments are usually thermodynamically incompatible, leading to phase separation, and thus to a microdomain structure which, depending on the chemical composition, can give rise to materials with a broad range of properties and applications6. Application list grows that women mascaras, hair conditioners, parquet varnishes, denim coatings, sport-wears, work-safety cloths, dispersing additives for coating formulations, bonding agents, self-healing binders, etc.7. PUDs can be used as adhesives, coating materials, co-binders, sizing agents and UV-curable binders8.

In a typical PUD synthesis, an isocyanate (NCO) terminated pre-polymer is first synthesized by stepgrowth polymerization that contains a stabilizing hydrophilic moiety, and an excess of diisocyanate (NCO / OH >1) in a solvent such as acetone or methyl ethyl ketone. Following this, the PU prepolymer is dispersed in water to form spontaneously self assembled micelle-like structures. The dispersed prepolymer is then chain extended using a diamine to give a high molecular weight polymer and the solvent removed. This self assembled micelle-like dispersed product is emulsifed by internally so this gives the dispersed product sensitivity against to temperature changes.

[caption id="attachment_137031" align="aligncenter" width="1197"] Figure 3. Schematic for main ingredients of PUDs (polyurethane-urea dispersions) structure[/caption]

Unique chemistry of PUDs provide UV resistance, abrasion resistance, scratch resistance, moisture management, hydrophobicity-hydrophility, gloss control, tensile strentgh, peelable, wash resistance, impact resistance, adhesion strenth, the list goes on. Because of that, they have a widespread literature coverage.

Distruptive studies based on polyurethane dispersion for Fluorine-free water-proofing agent is still on demand9. It is not new but it still hot topic that the use of elements like phosphorous, sulfur, silicon; chemical and physical modifications enhance the thermal and mechanical properties of PUDs10. Based on a recent works, polyurethane (PU) / acrylic hybrid dispersions are an important class of polymeric dispersions that are produced on an industrial scale. It helps to that the products require much fewer film-forming agents for flooring and furniture coating11.

Using less isocyanate or none-isocyanate applications have been one of the important challenges of the industry for last two decades. New ways for the synthesis of PUDs having less or none-isocyanate is going to be more important in the future. There are lots of EU-funded projects that accept the challenge of the industry and try to combine these problems and give a ‘hybrid’ solution as a technology offering. Polyhydroxyurethanes (PHU) are the most promising polymers that helps using less isocyanate in the polymer backbone but it needs to be more challange to be waterborne dispersion. V. Besse et al summarizes that how PHU’s have low molecular weights12. This explains that why polyurethanes could not be fully PHU’s based now.

Furthermore, reputable companies who are the pioneers of urethane industry acquires the start-ups to use renewable feedstocks for greener polyurethane industry. The functions of wood coatings, the functions of technical textile coating, the binders for recycled composite material are emerging trends for the national economy, especially for EU harmonization

studies.

In 2050, European based chemical industry will use and produce more carbonized (CO2 based) products. A project, received funding from the European Union and aimed at researching and developing a new technology that can transform CO2 and carbon

monoxide (CO) into polyols13. In the literature, there is a work on synthesized product of waterborne polyurethane dispersions (WPUDs) from upcycled polyols in foam production demonstrated suitable viability of polyurethane products synthesized from virgin polyol14.

To conclude, the versatility in composition, properties, processing and applicability of PUDs make them promising materials that may evolve to new fields needing novel and specific requirements.

References

1. Alrashed M., 2013. “Polyurethane / Polysiloxane Ceramer Nanocomposite Coating for. Aircraft Applications” Thesis Advisor: Dr. Sadhan Jana. Rostyslav Dolog, Ph.D.

2. Mark F. Sonnenschein, 2020. Polyurethanes: Science, Technology, Markets, and Trends, 2nd Edition, | Hoboken : Wiley, 2021. | Series: Wiley series on polymer engineering and technology

3. Ground Level Ozone Pollution, Volatile Organic Compound, United States Environmental Protection Agency (EPA) website

4. Global Overview of PUDs, Coating Industry-EMEA, IAL Consultants Market Report-2021

5. Bayer Materials Science, Coating 2013 Press Release

6. Erol Yildirim, Mine Yurtsever, Emel Yilgör, Iskender Yilgör,Garth L. Wilkes. Temperature-dependent changes in the hydrogen bonded hard segment network and microphase morphology in a model polyurethane: Experimental and simulation studies. Journal of Polymer Science Part B: Polymer Physics 2018, 56 (2) , 182-192.

7. Berezkin, Y., P.D. Schmitt, and S. Unal, Polyurethane dispersions for use in personal care products, 2008, Bayer Materialscience LLC, USA . p. 13pp

8. US9862824B2 ,Carbon fiber sizing agent, aqueous dispersion thereof, carbon fiber bundle applied with sizing agent, sheet-like article comprising carbon fiber bundle, and carbon fiber reinforced composite material

9. CN103628324A, Fluorine-free water-proofing agent and preparation

method thereof as well as textile

10. Swapnil M. Vaidya, et al., Recent developments in waterborne polyurethane dispersions (WPUDs): a mini‑review on thermal and mechanical properties improvement, 2021,Springer Nature

11. Samane Mehravar, Nicholas Ballard, Radmila Tomovska, and José M. Asua, 2019. Polyurethane(PU) / acrylic hybrid waterborne dispersions: Synthesis, properties and applications Ind. Eng. Chem. Res.,

12. V. Besse et al, How to explain low molar masses in PolyHydroxyUrethanes (PHUs), European Polymer Journal 71 (2015) 1-11

13. Carbon4PUR Press Release

14. Iyer D., Srivastava S., ‘Upcycled Polyurethane Products Based Waterborne Polyurethane Dispersions’,Mattress Recycling Council Dispersion Report,2020

Figure 3. Schematic for main ingredients of PUDs (polyurethane-urea dispersions) structure[/caption]

Unique chemistry of PUDs provide UV resistance, abrasion resistance, scratch resistance, moisture management, hydrophobicity-hydrophility, gloss control, tensile strentgh, peelable, wash resistance, impact resistance, adhesion strenth, the list goes on. Because of that, they have a widespread literature coverage.

Distruptive studies based on polyurethane dispersion for Fluorine-free water-proofing agent is still on demand9. It is not new but it still hot topic that the use of elements like phosphorous, sulfur, silicon; chemical and physical modifications enhance the thermal and mechanical properties of PUDs10. Based on a recent works, polyurethane (PU) / acrylic hybrid dispersions are an important class of polymeric dispersions that are produced on an industrial scale. It helps to that the products require much fewer film-forming agents for flooring and furniture coating11.

Using less isocyanate or none-isocyanate applications have been one of the important challenges of the industry for last two decades. New ways for the synthesis of PUDs having less or none-isocyanate is going to be more important in the future. There are lots of EU-funded projects that accept the challenge of the industry and try to combine these problems and give a ‘hybrid’ solution as a technology offering. Polyhydroxyurethanes (PHU) are the most promising polymers that helps using less isocyanate in the polymer backbone but it needs to be more challange to be waterborne dispersion. V. Besse et al summarizes that how PHU’s have low molecular weights12. This explains that why polyurethanes could not be fully PHU’s based now.

Furthermore, reputable companies who are the pioneers of urethane industry acquires the start-ups to use renewable feedstocks for greener polyurethane industry. The functions of wood coatings, the functions of technical textile coating, the binders for recycled composite material are emerging trends for the national economy, especially for EU harmonization

studies.

In 2050, European based chemical industry will use and produce more carbonized (CO2 based) products. A project, received funding from the European Union and aimed at researching and developing a new technology that can transform CO2 and carbon

monoxide (CO) into polyols13. In the literature, there is a work on synthesized product of waterborne polyurethane dispersions (WPUDs) from upcycled polyols in foam production demonstrated suitable viability of polyurethane products synthesized from virgin polyol14.

To conclude, the versatility in composition, properties, processing and applicability of PUDs make them promising materials that may evolve to new fields needing novel and specific requirements.

References

1. Alrashed M., 2013. “Polyurethane / Polysiloxane Ceramer Nanocomposite Coating for. Aircraft Applications” Thesis Advisor: Dr. Sadhan Jana. Rostyslav Dolog, Ph.D.

2. Mark F. Sonnenschein, 2020. Polyurethanes: Science, Technology, Markets, and Trends, 2nd Edition, | Hoboken : Wiley, 2021. | Series: Wiley series on polymer engineering and technology

3. Ground Level Ozone Pollution, Volatile Organic Compound, United States Environmental Protection Agency (EPA) website

4. Global Overview of PUDs, Coating Industry-EMEA, IAL Consultants Market Report-2021

5. Bayer Materials Science, Coating 2013 Press Release

6. Erol Yildirim, Mine Yurtsever, Emel Yilgör, Iskender Yilgör,Garth L. Wilkes. Temperature-dependent changes in the hydrogen bonded hard segment network and microphase morphology in a model polyurethane: Experimental and simulation studies. Journal of Polymer Science Part B: Polymer Physics 2018, 56 (2) , 182-192.

7. Berezkin, Y., P.D. Schmitt, and S. Unal, Polyurethane dispersions for use in personal care products, 2008, Bayer Materialscience LLC, USA . p. 13pp

8. US9862824B2 ,Carbon fiber sizing agent, aqueous dispersion thereof, carbon fiber bundle applied with sizing agent, sheet-like article comprising carbon fiber bundle, and carbon fiber reinforced composite material

9. CN103628324A, Fluorine-free water-proofing agent and preparation

method thereof as well as textile

10. Swapnil M. Vaidya, et al., Recent developments in waterborne polyurethane dispersions (WPUDs): a mini‑review on thermal and mechanical properties improvement, 2021,Springer Nature

11. Samane Mehravar, Nicholas Ballard, Radmila Tomovska, and José M. Asua, 2019. Polyurethane(PU) / acrylic hybrid waterborne dispersions: Synthesis, properties and applications Ind. Eng. Chem. Res.,

12. V. Besse et al, How to explain low molar masses in PolyHydroxyUrethanes (PHUs), European Polymer Journal 71 (2015) 1-11

13. Carbon4PUR Press Release

14. Iyer D., Srivastava S., ‘Upcycled Polyurethane Products Based Waterborne Polyurethane Dispersions’,Mattress Recycling Council Dispersion Report,2020