Carbon black is one of the oldest manufactured materials. Early uses can be traced back the ancient China, the early Egyptians and the production of Indian inks.

Carbon black is the name of a common black pigment, traditionally produced from charring organic materials such as wood or bone. Contemporary carbon black manufacturing began at early 1900’s in England.

Generally, carbon black, obtained by the incomplete combustion of gas or liquid hydrocarbon that is defined as carbon particles. These particles may be from 20 to 600 millimicrons in size.

A major portion of the carbon black production is obtained by complete combustion of natural gas and refined oil by processing in special furnaces. Today there is different kinds of carbon black production techniques.

The most Widely Production Techniques are Furnace Process and Gas Process.

All over the world, nearly 80-90% of the total carbon black is used in natural and synthetic rubber production. The main application areas of carbon black: printing and printing inks, paints, plastics, natural and synthetic rubber.

Carbon black is uses as black colorant in paints, printing inks, thermoplastic and thermosetting plastics but it is also used as filler to improve the strength of synthetic and natural rubber.

Asil Kimya supplies CARBONEX series of carbon black products since 2005. These products are: a high tinting strength, blue tone, good dispersion, and easily crushing with the optimum price-quality balance. CARBONEX series carbon blacks provide good gloss and a high degree of jetness in the final product.

CARBONEX series carbon blacks provide good gloss and a high degree of jetness in the final product.

CARBONEX group products are used in production of paints, inks, plastics, PVC/synthetic rubber, artificial leather and fiber dyeing.

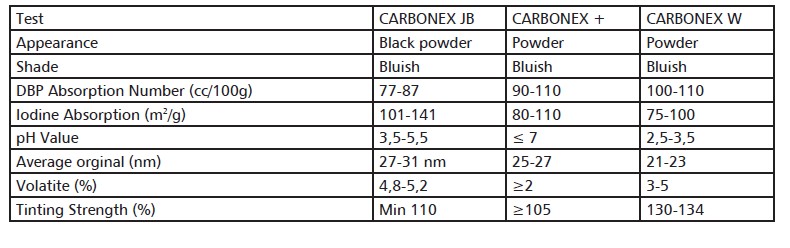

Properties:

Nihat Belbez

Sales Manager

Asil Kimya ve Boya San. Tic. A.Ş.