Strengthening and retrofitting of existing reinforced concrete (RC) structures against the earthquake effects has come into focus during the last decade. Credible earthquakes have shown that non-engineered RC frames are particularly vulnerable to the seismic action and are a major cause of loss of lives.

The structures with varying quality and function are all ageing and deteriorating in time. However, it is not only the deterioration fact that makes retrofitting necessary. Errors during design and/or construction might be the main reasons of retrofitting in order to prevent fatal disasters during earthquakes.

The general profile of low-rise structures in our country is mainly the infilled RC frames. They are not only lack-off engineering process, construction quality but also lack of design codes requirements.

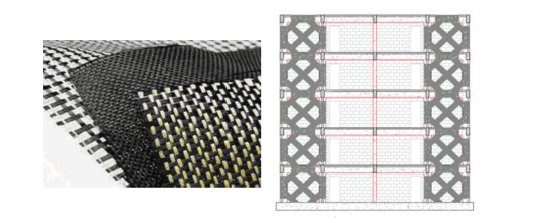

Some of these structures might need reconstruction since they are in such bad condition. However, instead of reconstruction; carbon fiber reinforced polymers (CFRP) has proven by many academic studies to be an effective material for strengthening of RC structures. A retrofitting proposal of Ozkaynak (2010) with CFRP sheets is presented in Figure 1.

In the case of confining the infill walls by the application of diamond bracing type CFRP scheme, the earthquake performance and energy dissipation characteristics of the existing RC structures could considerably be improved.

Figure 1. Carbon fibre reinforced polymers (CFRP) scheme proposed by Ozkaynak (2010)

The advantages of CFRP material are low weight, easy to apply, non-corrosiveness and high strength. Direct observation of damaged structures, following the Kocaeli- Turkey 1999 earthquake, main damage occurred usually within the near vicinity of beam-column joints, but some of them did not collapsed because they included infill walls.

These observations on the infilled RC structures, proves that infill walls are essential in improving the stiffness, strength and damping properties as well as the energy dissipation capacities of the structures provided that their out of plane movement was restricted.

Moreover, using CFRP for retrofitting is of interest since it is very easy to be applied on the infill walls without disturbing the occupants living inside the buildings.

The most practical and efficient way to increase the strength level and to decrease the damage of structures is to increase the internal energy dissipation properties of the global structure. Integration of infill walls to the frame structures provides a great source of energy dissipation capacity.

The friction, which occurs through the interface of the infill walls and the structure, ensures to increase the structural inherent damping properties both in linear and nonlinear region, [2].

Past earthquakes and recent literature have proven that the infill walls are a great source of stiffness, strength and energy dissipation unless they are located in such a way that they are placed uniformly and they do not cause any short column affects or torsional discontinuities, [3].

Consequently, it should be noted that if the infill walls are very well integrated to the existing frame structures and if their possible out of plane behavior was restricted, the infill walls turnout to be the most essential non-structural components and have great advantages during earthquakes.

Here, several academic literatures are summarized, and in order to demonstrate the effects of CFRP sheets application on the mechanical characteristics of hollow brick wall mockups some experimental results are presented.

Ghanem et al., (1993) conducted a comprehensive test program included fourteen 1/3 scaled partially reinforced concrete masonry shear walls under in plane monotonical lateral loads with and without axial effects.

The test results showed that the axial compression has a significant effect on the failure mode, cracking load and load carrying capacity. Lafuente et al. (1998) investigated the seismic behavior of masonry walls experimentally and analytically.

They have performed four full scale, concrete block, structural masonry walls against lateral loads. The analytical study was based on finite element methods. Two of the specimens were internally reinforced and the rest of the two was built with confined masonry.

Conclusions do not support the procedure of taking the advantage of the inelastic behavior of the material for seismic resistant design. The suggested the exploration of other alternatives to obtain more ductile mechanisms.

Alshebani and Sinha, (1999) carried out series of tests on half-scale sand plast brickwork panels under uniaxial cyclic loading. Forty-two square panels were tested until the failure for two cases of loading which is normal to bed joint and parallel to bed joint.

It was concluded that the peak stress of stability point curve can be regarded as the maximum permissible stress which is almost equal to two-thirds of the failure stress. The permissible stress level depends on the plastic strain level present in the material due to cyclic loading.

H.H. Knutsson and J. Nielsen (1995) developed a standard test method for the determination of the modulus of elasticity and ultimate strength for masonry in compression. The curved stress-strain diagram for the material is approximated both by parabola and a logarithmic curve.

John Jai et al. (2000) developed a mathematical model to take the advantage of fiber-reinforced composite materials when used in retrofitting masonry buildings. The analytical model could predict the behavior of masonry walls reinforced with the composite layer subjected to static in plane normal and shear loads.

These models could provide guidance to the designer on how different types of reinforcement could affect the load carrying capacity of a masonry wall. In the same content of the research study one individual investigation was performed on the determining of experimental behavior of the reinforced masonry walls.

Three types of test specimens were constructed i) walls made of clay bricks and mortar and reinforced with chopped glass mat and epoxy resin ii) walls made of wood bricks and reinforced with paper, and iii) beams made of wood bricks and reinforced with paper.

There were good convergencies between the experimental analytical results. Reinhorn et al. (1985) carried out experimental research based on 23 masonry specimens, in two stages. The first one involved 10 pairs of thin ferrocement sheets which were used to define bonding, connector size and spacing.

The remaining 13 brick specimens were subjected to diagonal split tests. The results demonstrated quite well for the strength and ductility of the ferrocement- brick composite. Santa- Maria et al. (2004) performed experiments twentyfour unreinforced masonry (URM) panels reinforced with carbon fiber reinforced polymer (CFRP) laminates and sheets under the effects of diagonal compression.

Panels with two configurations of the reinforcement were subjected to monotonic and cyclic loading. The study reported the results of the experimental results in terms of strength, mechanism of failure, stiffness and energy dissipation.

External CFRP application minimized the thickness of the cracks and improved the shear strength and the stiffness. Vintzileou and Tassios (1995), investigated the effects of injecting cement-based grouts in three-leaf stone masonry on wallets which were subjected to vertical and diagonal compression.

A drastic improvement of mechanical characteristics was observed due to the homogenization of the three-leaf masonry after the injection of the grout. Sathiparan et al. (2009) proposed a retrofitting technique based on the use of polypropylene bands (PP bands), which are commonly utilized for packing.

In order to evaluate the beneficial effects of the proposed PP band mesh retrofitting method, diagonal shear test and out of plane tests were carried out on masonry wallets with and without retrofitting.

In diagonal shear tests, the masonry wallets were retrofitted with meshes whose borders were connected with either epoxy resin or just by overlapping to evaluate whether the connection type influences the retrofitting performance.

From both test results PP band retrofitted specimens resulted larger residual strength after the first crack in both in-plane and out-of-plane loading. This retrofitting technique improved the overall stability and ductility of structure. Gurgain et al. (2007), simulated the brick masonry wall behavior.

The effect of aspect ratio which governs the failure pattern was adopted to the analytical model. The simulation of the PP-band retrofitting was done with a simplified modelling of PP-band meshes.

The comparison of the behaviors between the retrofitted and non-retrofitted cases, numerically it was proved that PP-band application improved the earthquake safety. Krevaikas and Triantafillou (2005), investigated the application of fiber-reinforced polymer (FRP) to increase the axial capacity of masonry through confinement.

Four series of uniaxial compression tests, with a total of 42 specimens were conducted on model masonry columns in terms of layer numbers, radius at the corners, cross-section aspect ratio, and types of fibers. It was concluded that FRP-confined masonry behaved similar with FRP-confined concrete.

Confinement increased the load bearing capacity and deformability of masonry almost in elastic region. El-Dakhakhni et al. (2006), conducted several experiments in various directions to determine the behavior of RM and URM masonry wall elements and the infilled steel frames.

Experiments performed on about 24 specimens and were tested under the axial and the shear effects. Composite laminate elements were used for retrofitting. During the experiments out-of-plane movements were kept limited and significant improvements in terms of stiffness, strength and post peak behavior were ensured by the application of composite laminate.

The experiments resulted that composite laminates are effective in increasing the deformation ability and limiting severe damages. Farooq et al. (2006), tested masonry walls reinforced with steel plates in different configurations under axial and shear effects in two different groups.

The arrangement intervals of the steel plates were the parameters of the research. It was concluded that significant increases in compressive and shear strength could be achieved with the steel plates which were anchored to the masonry wall surface.

Alcaino and Santa Maria (2008) tested 16 pcs full scale masonry walls under the shear effects. CFRP composites were applied to the masonry walls in different directions and the test results were evaluated in terms of strength,

stiffness, ductility and energy consumption. Test results showed that strength could be increased by 13 to 84% and displacement capability could be increased by 51 to 146% by the use of strengthening. In conclusion the CFRP application improved the energy dissipation properties of the specimens.

In the experimental study, equivalent damping rate was also determined. It was proposed that the average displacement of the peak displacement of 0.29% could be taken as 8% in average.

Taghdi et al. (2000), constructed and tested four concrete block masonry wall elements and two reinforced concrete masonry wall elements were to represent non-ductile masonry and wall concretes. One of each wall element is surrounded by the steel plates in vertical or transverse direction.

Anchor bolts and steel elements were used for the connection to the foundation and the upper part of the element. According to the test results; strengthening, ductility and energy consumption properties were increased for the retrofitted specimens with steel elements.

Chang Wei et al. (2007), constructed 3 masonry wall elements with the dimensions of 1.5×1.5m in order to determine the ductility and horizontal load carrying capacity of masonry walls.

One of three specimens was not reinforced with CFRP and the other two were retrofitted and tested under the effects of constant vertical loads and lateral reversible static loads. Reinforcement techniques increased the ductility, horizontal load carrying capacity and energy dissipation characteristics of the wall elements.

Elgawady et al. (2007) investigated the behavior of seven ½-scale masonry walls before and after CFRP application, under the effects of constant vertical loads, and reversed cyclic horizontal displacement pattern.

The axial stiffness and the amount of fibre polymer materials is an important parameter in the lateral load bearing capacity, stiffness and energy consumption. Using over dense amount of FRP causes the wall to exhibit very brittle behavior. It was found that the damping rates of the retrofitted specimens were higher.

A comprehensive experimental program was conducted in Structural Earthquake Engineering Laboratory (STEELab) of Istanbul Technical University in Turkey, [21]. The main aim of the study was to determine the mechanical properties of hollow brick walls.

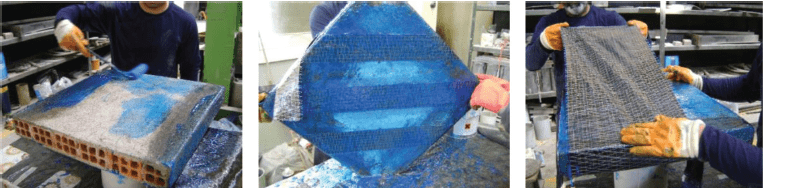

In order to achieve this purpose, several wall mockups were produced with the dimensions of 350×350×70 mm3. The hollow clay bricks, which had a void ratio of about 40%, were used to build the walls. The unit weight of CFRP is 0.0015 g/cm2.

The tensile strength is 3900 MPa and the modulus of elasticity of CFRP is 230 GPa. Fibre reinforced polymers were applied to the wall mockups. Some photos during the application of CFRP sheets on the wall mockups are presented Figure 2.

Surface Preparation Semi CFRP Application Full CFRP Application

Figure 2. CFRP Application stages

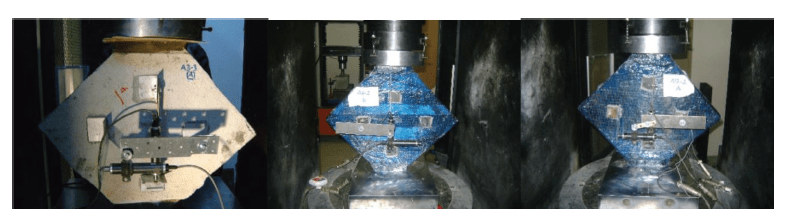

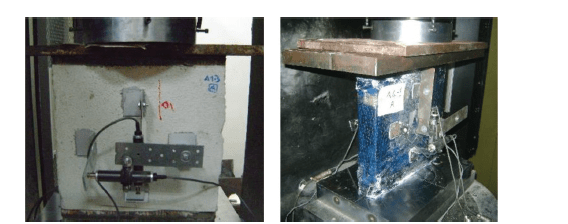

The tests were performed in two groups in order to determine both the shear and compressive strength. The amount of CFRP is the parameter in the first group experiments. The testing set-up and the specimens for the case of shear experiments could be seen in Figure 3.

Bare Specimen Semi-CFRP Full CFRP

Figure 3. First group specimens

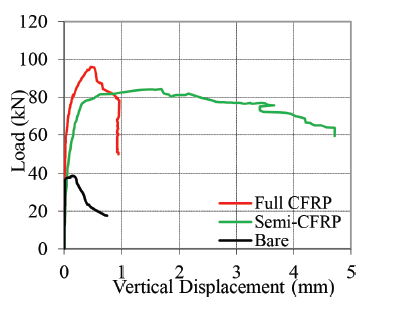

The force vs. displacement relations of compression tests which derived from the first group mock-up tests are given in Figure 4. Displacement data was recorded from the displacement transducers, which were located in vertical and horizontal directions.

Figure 4. Load vs. displacement relations derived from first group experiments

The improvement in shear strength was outstanding and almost similar with the strip type (Semi-CFRP) and full surface type (Full CFRP) retrofitting. It could be concluded that semi-CFRP confinement type of infill walls resulted with better shear deformation capacity than the full CFRP application.

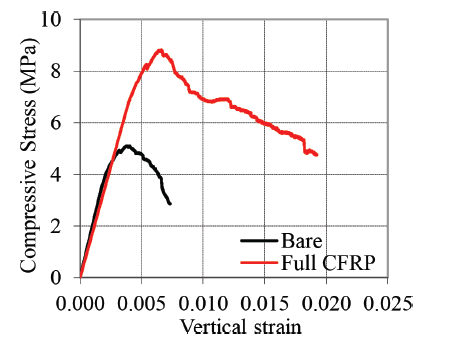

The specimens belong to the second group experiments are given Figure 5. The main aim of this group of experiments is to determine the effects of CFRP application on the compressive strength of the specimens. The load was applied in parallel direction to the brick holes.

Bare Specimen Semi-CFRP

Figure 5. Second group specimens

The compressive stress vs. vertical strain relations derived from second group experiments are given in Figure 6. The strain values were extracted from the displacement transducers which were vertically mounted on the wall mock-ups.

Figure 6. Compressive stress vs. vertical strain relations derived from second group experiments

CFRP retrofitting provided great improvement in terms of compressive and shear strength, and deformability of infill walls, there were few local CFRP torn at the head joint of both type of retrofitted wallets with some head mortar and brick crushing. In global for all the specimen’s similar damages were observed.

It can be concluded that by the use of CFRP sheets a great improvement of the overall performance can be achieved. These retrofitting techniques can minimize the crack widths and results with more ductile behavior. CFRP application could prevent the brittle shear failures of the infill wall.

In practical CFRP retrofitting technique, have advantages not only in the technical scope (strength, stiffness, energy dissipation) but also in labor and material costs. In this frame, the total cost could considerably be reduced when it is compared with other conventional techniques such as constructing shear RC walls and/ or jacketing structural elements.

Acknowledgments

This study basis on the test results which were conducted at the Material Laboratory and the Structural and Earthquake Engineering Laboratory of Istanbul Technical University. It was sponsored by research Project 106M050 of the Scientific and Technological Research Council of Turkey (TUBITAK) and by BASF company. The author is thankful to the supporters and to Prof. Dr. Ercan Yüksel, Prof. Dr. Alper İlki and Dr. Medine İspir.

Doç. Dr. Hasan Özkaynak – Beykent University Faculty of Engineering and Architecture Civil Engineering Department

References

[1] Özkaynak H. “The earthquake behavior of RC frames with fiber polymer confined infill walls and their structural damping properties”. Ph.D. Thesis, Istanbul

Technical University, Istanbul, 2010, (in Turkish).

[2] H. Ozkaynak, E. Yuksel, C. Yalcin, A. A. Dindar and O. Buyukozturk, “Masonry infill walls in reinforced concrete frames as a sourc of structural damping” EARTHQUAKE ENGINEERING & STRUCTURAL DYNAMICS 2014; 43:949–968

[3] Dolsek M, Fajfar P. “The effects of masonry infills on the seismic response of a four-storey reinforced concrete frame a deterministic assessment.” Engineering

Structures 2008; 30:1991–2001.

[4] Ghanem, Salama, Elmagd and Hamid “Effect of Axial Compression on the behavior of partially reinforced masonry shear walls” The 6th North American Masonry

Conference Philadelphia Pennsylvania June 6-9, 1993

[5] Marianela Lafuente, Enrique Castilla And Carlos Genatios Imme “Experimental and Analytical Evaluation of the Seismic Resistant Behaviour of Masonry Walls”,

International Masonry Society, Universidad Central de Venezuela. Vol 11, No 3, 1998.

[6] Milad M. AlShebani and s.N. Sinha “Stress-Strain Characteristics of Brick Masonry Under Uniaxial Cyclic Loading” Journal of Structural Engineering Vol.125,

No. 6, 1999. @ASCE ISSN 0733-9445/99/0600-0604

[7] H.H. Knutsson and J. Nielsen, “On the modulus of Elasticity for Masonry” Masonry International Vol.9, No.2, pp.57-61, 1995.

[8] John Jai, George S. Springer, László P. Kollár, Helmut Krawinkler, “Reinforcing Masonry Walls with Composite Materials-Model” Journal of Composite Materials

34(18):1548-1581 DOI: 10.1106/38XX-GGB5-NXC9-TJHA, September 2000

[9] Reinhorn, A.M., Prawel, S.P. and Jia, Z.H. “Experimental study of ferrocement as a seismic retrofit material of masonry walls” Journal of Ferrocement, Vol. 15,

no.3 July, 1985.

[10] Hernan Santa-Maria, Gozalo Duarte, Aleandro Garib. “Experimental Investigation of Masonry Panels Externally Stregthened with CFRP Laminates and Fabric

Subjected to In-Plane Shear Load” 13th World Conference on Earthquake Engineering. Vancouver, B.B., Canada. Aug.1-6.2004

[11] Elizabeth Vintzileou and Theodossios P. Tassios “Three-Leaf Stone Masonry Stregthened By Injecting Cement Grouts” Journal of Structural Engineering

Vol.121 No.5, May6.1995ASCE.

[12] Navaratnarajah Sthiparan, Paola Mayorca, Kourosh Nasrollahzadeh Nesheli, Ramesh Guragain and Kimiro Meguro. “Experimental Study of PP-Band Retrofitted

Masonry Wallettes” Institute of Industrial Science University of Tokyo. January 2009 DOI: 10.11188/seisankenkyu.61.1051

[13] Ramesh Guragain, Kawin Worakanchana, Kimiro Meguro, Paola Mayorca “Simulation of Brick Masonry Wall Behavior Under Cyclic Loading Using Applied

Element Method” Institute of Industrial Science University of Tokyo.Bull. ERS.No. 40 (2007)

[14] Theofanis D. Krevaikas and Thanasis C. Triantafillou, “Masonry Confinement with Fiber-Reinforced Polymers” Journal of Composites for Construction DOI:

10.1061/(ASCE)1090-0268(2005)9:2(128) March 2005.

[15] W.W. El-Dakhakhni, A.A. Hamid, Z.H.R. Hakam, M. Elgaaly. “Hazard mitigation and strengthening of unreinforced masonry walls using composites” doi:

10.1016/2005.02.017 Journal of Composite Structures. Volume 73, Issue 4, June 2006, Pages 458-477

[16] Farooq, M. Ilyas and A. Ghaffar “Technıque For Strengthenıng Of Masonry Wall Panels Usıng Steel Strıps”ASIAN JOURNAL OF CIVIL ENGINEERING (BUILDING

AND HOUSING) VOL. 7, NO. 6 (2006) PAGES 621-638

[17] Pablo Alcaino ve Hernan Santa-Maria, “Experimental Response of Externally Retrofitted Masonry Walls Subjected to Shear Loading” M. ASCE. doi: 10.1061/

ASCE1090-0268(2008)12:5(489-498) Journal of Composites for Construction @ ASCE

[18] Mustafa Taghdi, Michel Bruneau, Murat Saatcioglu “Seismic Retrofitting of Low-Rise Masonry and Concrete Walls Using Steel Strips” Journal of Structural

Engineering 126(9)DOI: 10.1061/(ASCE)0733-9445(2000)126:9(1017) September 2000

[19] Chang-Qin Wei, Xin-Gang Zhou, Lie-Ping Ye “Experimental study of masonry walls strengthened with CFRP” Chang-Qin Wei, Xin-Gang Zhou, Lie-Ping Ye, Structural Engineering and Mechanics, Vol.25, No.6(2007) 675-690.

[20] ElGawady MA, Lestuzzi P, Badoux M. “Static cyclic response of masonry walls retrofitted with fiber-reinforced polymers.” J Compos Construct 2007;11(1):50–

61.

[21] OZSAYIN, B., E. YILMAZ, M. ISPIR, H. OZKAYNAK, E. YUKSEL and A. ILKİ, “Characteristics of CFRP Retrofitted Hollow Brick Walls of Reinforced Concrete Frames”, Construction and BUILDING MATERIALS, 25(10), 4017-4024, 2011.