Confined spaces are common in all plants in various types. Sometimes once a week, sometimes once a month, and sometimes once a year, we need to work in confined areas, but the main issue is to access it rather than how often we should work there, to effectively work in this space and to have the ability of rescuing the workers in case of an adverse incident. It is critical for our risk assessment and emergency action plan to be accurate, adequate, and feasible to do all this.

In general, 4 steps should be followed for works in confined spaces.

1- Planning: Risk assessment and emergency action plan,

2- Access,

3- Working inside,

4- Rescue.

Before discussing these 4 steps, it would be beneficial to explain the term confined space. Confined space can be defined through 3 main questions based on the definition of the US OSHA (Occupational Safety and Health Administration).

1- Is it large enough and so configured that an employee can bodily enter and perform assigned work?

2- Does it have limited or restricted means for entry or exit?

3- Is it not designed for continuous employee occupancy?

If you give the answer “yes” to all three of these questions, you need to ask one other question. “Does the space have any other serious health or safety hazard, such as engulfment, entrapment, asphyxiation, atmospheric hazards, etc.” If your answer to this question is “yes”, then the space you work at should be called a confined space that requires permission to enter.

Risk analysis should definitely be performed before doing any work in the confined area, and a drill should be conducted with the equipment to be used before the actual work to test the operation and use of such equipment.

The second step, i.e., the access requires checking whether the entrance of the confined space is vertical or horizontal. Access and rescue solutions may be configured based on that information. As a general rule, a tripod is made ready and available against any emergencies in plants in Turkey.

However, one must remember that, in any emergencies, bringing the tripod to the scene of incident and installing it will take time. Therefore, the tripod should be installed as soon as the worker enters the space before an incident ever happens. Another matter is that tripod is not suitable for any spaces.

For instance, if the worker is to enter the space horizontally, installing a tripod will not be the best approach. Another matter to consider is that, the floor where you install the tripod should be smooth and leveled so that the tripod stands well-balanced.

Lastly, if the worker falls down and/or the worker loses consciousness and requires to be rescued, the rescuer should make a physical attempt to take the worker into a safe space once the worker has been uplifted by the tripod.

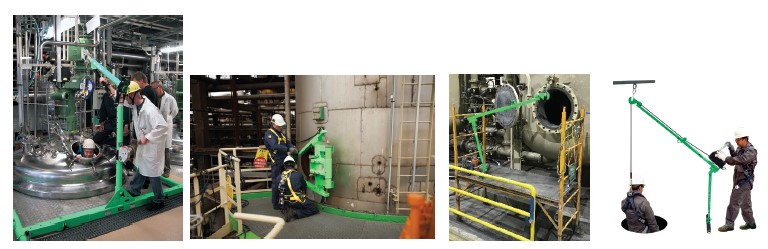

However, as the below picture shows, it is possible to access and rescue the workers through different solutions.

For example, 5-component systems (Figure 1) for vertical entrances such as tank entrances, horizontal entrance equipment to be used in horizontal entrances (Figure 2) or light and mobile systems to be used for both vertical and horizontal entrances (Figure 3, Figure 4) should be assessed specifically for each entrance and selected depending on their conformity.

Figure 1. 5-component Davit System Figure 2. Systems for horizontal entrances Figure 3.Horizontal entrance exampleFigure 4. Vertical entrance example

After selecting the anchorage points for accessing the confined space, it is also important to correctly select the body support that the worker will be wearing while inside.

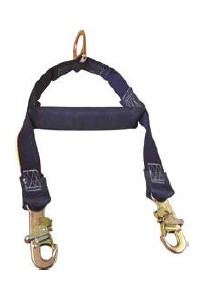

Adding the suspension tool to the safety harness with a D-ring at the shoulders will allow the worker to easily and more comfortably enter and exit the confined space (Figure 5). Aside from the worker’s comfort, selecting a harness that fits the work to be performed inside the confined space is another factor affecting the safety.

For example, during welding works, the sparks and the burrs from welding may make a hole on the harness and hence lower its level of protection. Therefore, it is recommended to prefer products with Nomex/Kevlar material that is suitable for welding works.

Figure 5. Suspension Device

After selecting the safety harness and the anchorage point, crane and/or self-retractable fall arresters should be selected considering the work conditions to offer a safe working area for the worker. Periodic maintenance is critical for all the above 3 groups of components used for accessing the confined space and for rescuing.

Although the shelf life of equipment containing textile materials is established as 10 years, the usage life is determined with periodic checks. For mechanical products

(tripod, self-refractory fall arrester etc.),no usage issues are encountered as long as those go through a periodic examination.

However, it is important to take into consideration the recommendations of the manufacturer.

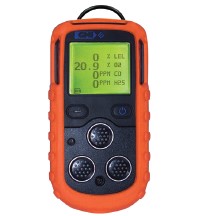

Figure 6. Pumped Gas Detector

Another factor to consider is the existence of any atmospheric hazard in the confined space or whether the work to be done (cleaning, painting, welding etc.) creates an extra atmospheric hazard.

Before entering inside the confined space, gas values at all values of the inner space should be read by selecting certain points both at entrance level and at distant levels. Pumped gas detectors (Figure 6) are usually preferred to measure the levels of the chemicals inside the confined space.

This allows safe inner environment measurements even at depths of 5, 10 or 15 meters. Nevertheless, one of the key points at this stage is to ensure that bump tests and calibration of the gas detectors are done correctly and timely.

Following gas measurements, the worker should wear personal protective equipment required in line with the nature of the work to be done inside as well as risk analysis before starting to work.

One of the most common issues at this point is to communicate with people wearing a respiratory protective equipment inside a confined space. Because communication is mostly established through radio, however, the masks that the workers wear on their faces disturb the clear relay of the workers’ voice via radio.

Those issues should be assessed depending on the characteristics of each space; but it is recommended to use systems that can clearly relay the voice to the radio through a microphone integrated into the positive-pressure masks (Figure 7 & 8).

Figure 7. Connection via Bluetooth Figure 8. Connection via cable

In the last stage, i.e., the rescue, the emergency plan should be followed and rescue teams should be made ready and available along with all their equipment.

Aside from correct equipment, risk analysis, and emergency action plan, one of the most critical points at confined space works is to ensure that both the workers and their supervisors have received the necessary training and have practiced drills on the use of the materials they will be using.

Mirey Bonfil

Advanced Application Engineer

Personal Safety Department

3M Türkiye