Dr. Michael Krebs

Regional Technology Manager EMEA

Evonik Nutrition&Care GmbH

Uğur Can İyidir

Technical Service Manager- Flexible Foam

Turkey&Middle East

Evonik Ticaret Ltd. Şti.

The reduction of the content of Volatile Organic Compounds (VOCs) continues to be an important issue in the polyurethane

industry. In order to cause less impact on the environment and to improve material safety, foam manufacturers across multiple

foam markets such as the spray foam, the automotive as well as the furniture and bedding sector are facing more and more

stringent regulations.

This trend to reduce emanations is also reflected by an increasing number of 3rd party institute certificates in the comfort

market such as LGA, CertiPUR, Ecolabel, to name but a few.

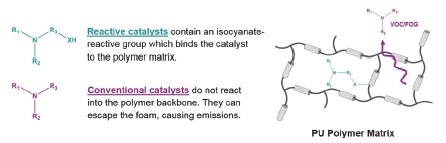

Amine catalysis is one of the key elements during the formation of polyurethane foam and although many components in PU foam

are responsible for emissions, amine catalysts are commonly targeted. Tertiary amines such as Bis (2-dimethylaminoethyl) ether

(BDE) and Triethylenediamine (TEDA) have been used for many years in the production of flexible polyurethane foam. However,

these catalysts are fugitive compounds with considerable volatility and thus they contribute significantly to VOC emanations.

Evonik has put big efforts and a lot of resources into the understanding of different mechanisms to minimize the amine contribution

to total VOC emissions of flexible PU foams (figure 1). In the past few years a variety of non-fugitive amine catalysts containing

isocyanate-reactive groups have been developed.

Figure 1. Difference in reactivity of conventional amine catalysts versus non-fugitive

amine catalysts

However, not all reactive catalysts are non-emissive. Although firmly bound into the polymer matrix amine catalysts can

decompose and migratory adducts can be formed which can contribute to the total VOC amount of the foam. Therefore, Evonik

DABCO® NE catalysts typically combine reactive groups with a high molecular weight and a high polarity. Furthermore, it is

important to reduce the amount of non-reactive, volatile by-products in the actual amine catalyst to a bare minimum. In order to

address these emission concerns the DABCO® NE series of amine catalysts show the highest standard of purity.

In addition to emissions and environmental requirements amine catalysts need to perform according to established guidelines to

meet high standards of physical property requirements so the mechanical performance of the finished product can be guaranteed.

The comfort industry has also devised a wide variety of tests to simulate the performance of foam over its life cycle. Once such

test relates to the chemical stability of foam and the testing methodology for evaluation employs severe conditions of heat and

humidity. These testing methodologies are used as tools to create guidelines for foam performance over time and also to simulate

accelerated conditions of foam ageing. Typically, catalysts that are retained in the Polyurethane polymer produce foam articles that

exhibit lower chemical stability when exposed to accelerated ageing conditions.

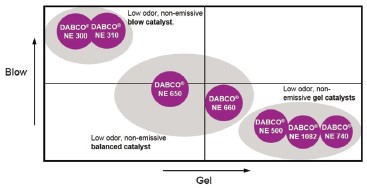

Evonik has now developed new catalyst technologies to help foam manufacturers meet the requirements of foam stability while

satisfying even more stringent emission requirements. The new catalyst technology is based on a combination of reactive blow

catalyst DABCO® NE 300, and a new gel catalyst DABCO® NE 740 (Figure 2).

Figure 2. Evonik portfolio of non-emissive amine catalysts for the region EMEA

Reactive Amine Catalysts with A High Blow Selectivity – DABCO® NE 300

DABCO® NE 300 is a reactive blow catalyst that exhibits zero amine emissions in various high temperature emanation tests for the

automotive industry (e.g. VDA 278) as well as in room temperature tests for comfort applications. DABCO® NE 300 offers similar

activity and foam physical properties compared to conventional blow catalysts such as DABCO® BL 11. Typically, it is possible to

equally replace DABCO® BL 11 by DABCO® NE 300 or with only a minor increase of the catalyst loading. This is illustrated in

figure 3 where an exchange of DABCO® BL 11 in a density 19 kg/m³ formulation by DABCO® NE 300 in a ratio of 1.1:1 resulted

in an equivalent rise profile.

Figure 3. Reaction profile of DABCO® NE 300 (blue curve) compared to DABCO® BL 11 (red curve) in a density 19 kg/m³ formulation

Due to its chemical structure DABCO® NE 300 generates very open, high-quality foam with excellent compression set

performance and it is readily miscible with polyols and polyol/water mixtures. Odour testing according to VDA 270 confirms that

DABCO® NE 300 manifests the lowest odor of commercially available reactive blow catalysts (Figure 4).

Figure 4. Odor evaluation of DABCO® NE 300

Latest Generation of Non-Fugitive Gel Catalysts – DABCO® NE 740

Besides a blowing optimized amine catalyst, in a multitude of formulations it is necessary to additionally use an amine catalyst

with improved gelling behaviour in order to have a balanced catalysis.

In recent years also reduced and non-emissive gel amine catalysts have been developed (DABCO® NE 500, DABCO® NE 1082,

TEGOAMIN® ZE types, etc.). However, they typically exhibit a lower activity and an insufficient gel selectivity compared to

DABCO® 33 LV. Therefore, non-fugitive gel amines with a similar performance have not been readily available.

Evonik has extended this research and recently developed a novel next generation non-emissive amine catalyst with high gel

selectivity called DABCO® NE 740. DABCO® NE 740 is used in flexible polyether slabstock foam applications to meet comfort

industry labels (LGA, OEKOTEX, Etc.), as well as automotive OEM emission specifications such as the new VDA 278 and

eliminates windshield fogging or vinyl staining.

DABCO® NE 740 is intended to be used for the production of various types of flexible polyurethane foam such as standard

polyether slabstock foam, viscoelastic foam or high resilient foam. In comparison to other non-fugitive catalysts it allows the

production of flexible polyurethane foam with excellent aging properties including thermal ageing, wet ageing and compression

set. Due to its outstanding gel selectivity, DABCO® NE 740 is perfectly suited for the production of low-emission viscoelastic

foams (based on TDI or MDI) and hyper soft foams. Typically, DABCO® 33 LV can be completely replaced by DABCO® NE 740

when increasing the amount of the non-fugitive catalyst only by 10 – 30% depending on the formulation.

In figure 5 the reaction profiles of two foams of density 21 kg/m³ are shown, one made with 0.11 parts of DABCO® 33 LV and one

made with 0.14 parts DABCO® NE 740. It is obvious that both curves basically are two of a kind in terms of rise time, foam height

as well as curve progression.

Figure 5. Reaction profile of DABCO® NE 740 (red curve) compared to DABCO® 33 LV (red curve) in a density 21 kg/m³ formulation

In order to judge the gel selectivity of the new amine catalyst long curing visco foams were prepared with DABCO® NE 740 in

comparison to DABCO® 33 LV. The results are shown in figure 6. A similar rise profile was supposed to be obtained and therefore,

an excess of 20% of DABCO® NE 740 had to be used compared to DABCO® 33 LV.

With this elevated usage level on the other hand the tack free time of the foam prepared with the reactive catalyst decreased

significantly from 90 s to 65 s.

Figure 6. Formulation and properties of two TDI 80 Visco foams, one made with DABCO® NE 740 and one made with DABCO® 33 LV

For flexible foam products the use of DABCO®NE 300 in combination with newly developed gelling catalyst DABCO®NE 740

results in foam materials essentially free of amine emissions according to the thermal desorption method VDA 278 and DIN

16000-9 (chamber test). Significant improvement compared to existing non-fugitive gel amine catalysts could be achieved with

the new gel optimized amine catalyst DABCO® NE 740 in terms of activity and gel selectivity. End-curing of visco foams for

example is comparable to the industry standard DABCO® 33 LV.

The advantage of using DABCO® NE 300 with the new gel catalyst DABCO® NE 740 is that;

1. This combination of catalysts allows foam producers to prepare flexible polyurethane foam materials,can satisfy the physical

property requirements particularly under accelerated humid aging with no emantions,

2. Establish non-emissive standards,

3. No impact odour.

With the broad spectrum of demands to improve comfort, durability, processability, physical properties, and reduction or

elimination of VOC emissions, Evonik Industries AG will continue to develop new technologies that will allow polyurethane

formulators and manufacturers to meet the ever-changing requirements of the industry. The polyurethane foam consumers can

certainly expect to enjoy higher standards of foam quality with the use of these newly developed polyurethane additives.

Note: All foams produced for this study were made by hand pouring in the laboratory.