What is Spray Polyurethane Rigid Foam?

Today thermal insulation is the biggest factor for the energy saving. At this point, rigid polyurethane foam which has closed cell structure is the material having the lowest heat transfer coefficient (0,018-0,022 W/mK) in the world. This type of polyurethane foam can be applied easily by spraying on the surface on which the thermal insulation is necessary. Polyurethane adheres and expands on the surface and forms a foam layer of 20-40 kg/m3 density enabling an effective thermal insulation.

How is Spray Polyurethane Foam Applied?

A spray machine is needed to apply this type of polyurethane foam. This machine withdraws polyol and isocyanate components from their drums, heats them up to 35-45oC and pumps them to their hoses with high pressure. The hoses are also heated to the same temperature to prevent cooling of components. After 15-30 m length, polyol and isocyanate component’s hoses are combined in the mixing chamber of the pistol. When the trigger of

the pistol is pulled, the components coming to the pistol are mixed together and sprayed on the surface with the help of the pressurized air fed to the pistol. Polyol and isocyanate components react with each other when they are mixed together and they expand when they reach the surface and form the polyurethane foam structure. In seconds, the expanded polyurethane foam comprises an effective thermal insulation layer.

[caption id="attachment_157326" align="aligncenter" width="537"]

Resim 1. Sprey Poliüretan Köpükle Yalıtım[/caption]

Thermal Insulation of Spray Polyurethane Foam

Spray polyurethane foams are expanded by both chemical blowing agents (water) and physical blowing agents(low boiling point hydrocarbons). Since this type of foams

have closed cells majorly, the gases generated from those blowing agents (carbondioxide and hydrocarbon gases) are trapped inside the cellular structure of the foam. At this point the thermal conductivity of the foam, which is the inverse of the thermal insulation, is affected by the three parameters below.

- The thermal conductivity of the polyurethane solid,

- The thermal conductivity of the entrapped gases,

- The density and the cell size of the foam.

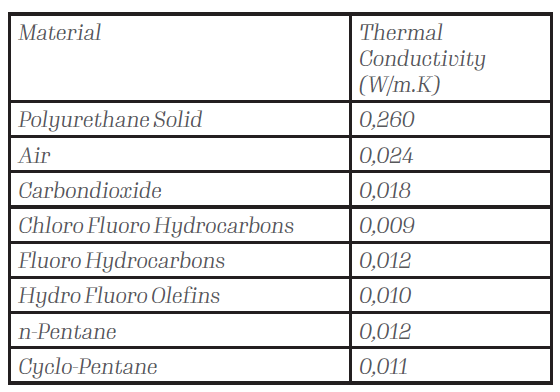

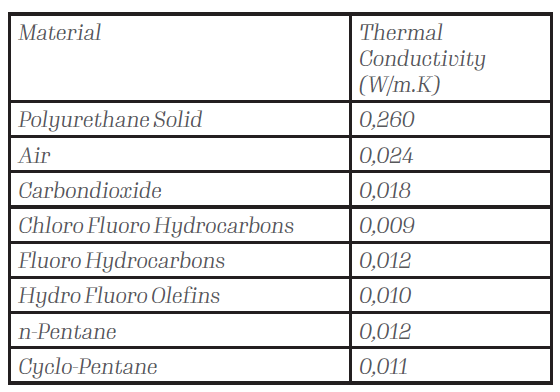

The thermal conductivities (ʎ) of some materials at the room temperature that can be used in the polyurethane foam structure are given in the table below.

[caption id="attachment_157332" align="aligncenter" width="560"]

Table 1. Thermal Conductivity of the Materials in the

Foam[/caption]

The thermal conductivity of the polyurethane solid material is constant but the polyurethane solid occupies only %5 of the foam volume generally for the common insulation densities (20-50 kg/m3).

Hence the thermal conductivity of the foam depends highly on the type of the blowing gas. The selection of the blowing gas must be made considering the thermal conductivity, the flammability, the environmental regulations and the price of the material.

The thermal conductivity of the foam increases (insulation decreases) with the increasing density of the foam because of the smaller space left for the gas and high radiation effect. The targeted thermal conductivity of the polyurethane foam should be 0,020 W/m.K or less.

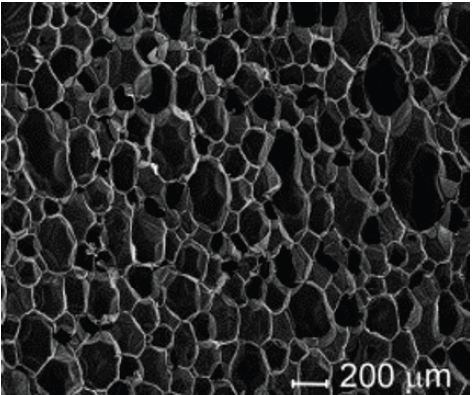

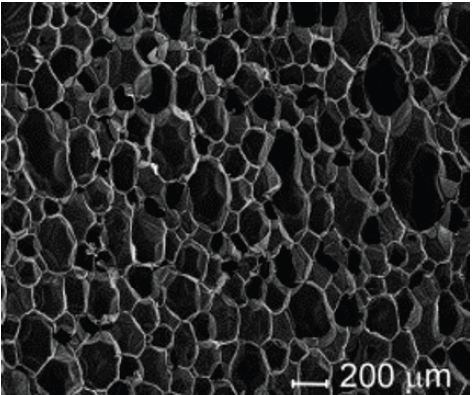

[caption id="attachment_157344" align="aligncenter" width="472"]

Figure 2. Cell Structure of the Rigid Polyurethane Foam[/caption]

To reach the minimum thermal conductivity, the foam should be at a low density but the cells of its should be closed enough to prevent the blowing gas from escaping outside. Otherwise hydrocarbon gas would be replaced by air, resulting in an increase of the thermal conductivity and reduction of the insulation property of the foam.

On the other hand, if the cells are all closed (>%95) and the density is low (<25 kg/m3), the rigid foam would have a tendency to shrink. To overcome the shrinkage problem at low densities, the cells should be open at a high ratio, which again increases the thermal conductivity as mentioned above.

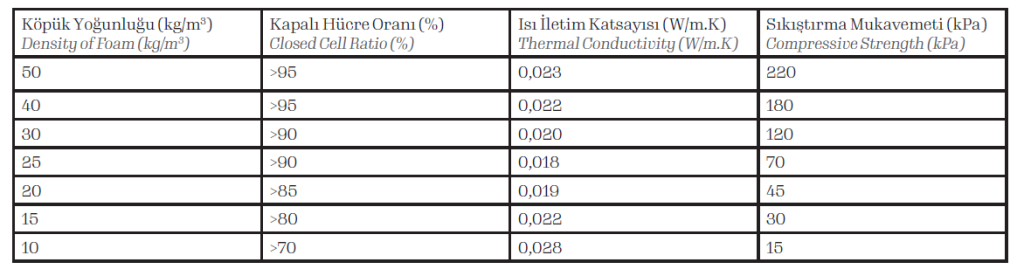

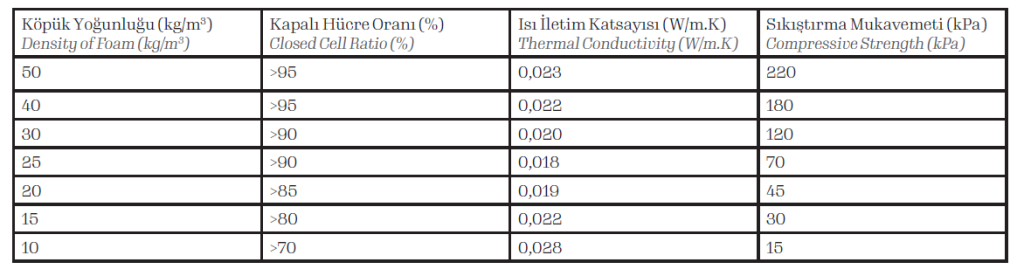

Also the mechanical strength of the foam must be considered because the low density foams are weaker. Therefore the design of the insulation foam is a matter of balance and optimization. For a cyclo-pentane blown foam, the thermal conductivity and the compressive strength of the foam are given below for various densities.

[caption id="attachment_157345" align="aligncenter" width="696"]

Table 2. Thermal Conductivity and Compressive Strength Values of Rigid Foam[/caption]

As seen from the table, if the foam is for ceiling insulation(not to walk on it), the right density of the rigid foam would be 20-25 kg/m3 and if the foam is for rooftop insulation, the right density should be 30-40 kg/m3.

Spray polyurethane foams have a density increase during the application comparing to their free rise density. Applied density becomes 1,3-1,4 times more than their free rise density. So for 20-25 kg/m3 applied density, the free rise density of the foam should be 15-18 kg/m3.

[caption id="attachment_157346" align="aligncenter" width="403"]

Figure 3. Spray Polyurethane Foam Application[/caption]

Poleks Kimya produces spray foam systems ranging from 12 kg/m3 to 40 kg/m3 free rise densities for all kinds of insulation purposes and helps the applicators in selecting the right density of the spray foam.

References

Soloveva O., Solovev S., Vankov Y., Experimental Studies of the Effective Thermal Conductivity of Polyurethane Foams with Different

Morphologies, MDPI Processes 10: 2257, September 2022.

Yakushin V. And Pauliks R., Properties of Polyurethane Foam with 4th Generation Blowing Agent, e-polymers 21: 763-769, September

2021.

Carrico C., Fraga T., Carvalho V., Polyurethane Foams for Thermal Insulation Uses, MDPI Molecules 22: 1091, April 2017.

Federation of European Rigid Polyurethane Foam Associations, Thermal Insulation Materials Made of Rigid Polyurethane Foam,

October 2007.

Jarfelt U. and Ramnas O., Thermal Conductivity of Polyurethane Foam : Best Performance, 10 th International Symposium on District

Heating and Cooling, Sept. 3-5 2006.

Yücel Aktay

R&D and Technical Support Manager

Poleks Kimya

Resim 1. Sprey Poliüretan Köpükle Yalıtım[/caption]

Resim 1. Sprey Poliüretan Köpükle Yalıtım[/caption]

Table 1. Thermal Conductivity of the Materials in the

Table 1. Thermal Conductivity of the Materials in the Figure 2. Cell Structure of the Rigid Polyurethane Foam[/caption]

To reach the minimum thermal conductivity, the foam should be at a low density but the cells of its should be closed enough to prevent the blowing gas from escaping outside. Otherwise hydrocarbon gas would be replaced by air, resulting in an increase of the thermal conductivity and reduction of the insulation property of the foam.

On the other hand, if the cells are all closed (>%95) and the density is low (<25 kg/m3), the rigid foam would have a tendency to shrink. To overcome the shrinkage problem at low densities, the cells should be open at a high ratio, which again increases the thermal conductivity as mentioned above.

Also the mechanical strength of the foam must be considered because the low density foams are weaker. Therefore the design of the insulation foam is a matter of balance and optimization. For a cyclo-pentane blown foam, the thermal conductivity and the compressive strength of the foam are given below for various densities.

[caption id="attachment_157345" align="aligncenter" width="696"]

Figure 2. Cell Structure of the Rigid Polyurethane Foam[/caption]

To reach the minimum thermal conductivity, the foam should be at a low density but the cells of its should be closed enough to prevent the blowing gas from escaping outside. Otherwise hydrocarbon gas would be replaced by air, resulting in an increase of the thermal conductivity and reduction of the insulation property of the foam.

On the other hand, if the cells are all closed (>%95) and the density is low (<25 kg/m3), the rigid foam would have a tendency to shrink. To overcome the shrinkage problem at low densities, the cells should be open at a high ratio, which again increases the thermal conductivity as mentioned above.

Also the mechanical strength of the foam must be considered because the low density foams are weaker. Therefore the design of the insulation foam is a matter of balance and optimization. For a cyclo-pentane blown foam, the thermal conductivity and the compressive strength of the foam are given below for various densities.

[caption id="attachment_157345" align="aligncenter" width="696"] Table 2. Thermal Conductivity and Compressive Strength Values of Rigid Foam[/caption]

As seen from the table, if the foam is for ceiling insulation(not to walk on it), the right density of the rigid foam would be 20-25 kg/m3 and if the foam is for rooftop insulation, the right density should be 30-40 kg/m3.

Spray polyurethane foams have a density increase during the application comparing to their free rise density. Applied density becomes 1,3-1,4 times more than their free rise density. So for 20-25 kg/m3 applied density, the free rise density of the foam should be 15-18 kg/m3.

[caption id="attachment_157346" align="aligncenter" width="403"]

Table 2. Thermal Conductivity and Compressive Strength Values of Rigid Foam[/caption]

As seen from the table, if the foam is for ceiling insulation(not to walk on it), the right density of the rigid foam would be 20-25 kg/m3 and if the foam is for rooftop insulation, the right density should be 30-40 kg/m3.

Spray polyurethane foams have a density increase during the application comparing to their free rise density. Applied density becomes 1,3-1,4 times more than their free rise density. So for 20-25 kg/m3 applied density, the free rise density of the foam should be 15-18 kg/m3.

[caption id="attachment_157346" align="aligncenter" width="403"] Figure 3. Spray Polyurethane Foam Application[/caption]

Poleks Kimya produces spray foam systems ranging from 12 kg/m3 to 40 kg/m3 free rise densities for all kinds of insulation purposes and helps the applicators in selecting the right density of the spray foam.

References

Soloveva O., Solovev S., Vankov Y., Experimental Studies of the Effective Thermal Conductivity of Polyurethane Foams with Different

Morphologies, MDPI Processes 10: 2257, September 2022.

Yakushin V. And Pauliks R., Properties of Polyurethane Foam with 4th Generation Blowing Agent, e-polymers 21: 763-769, September

2021.

Carrico C., Fraga T., Carvalho V., Polyurethane Foams for Thermal Insulation Uses, MDPI Molecules 22: 1091, April 2017.

Federation of European Rigid Polyurethane Foam Associations, Thermal Insulation Materials Made of Rigid Polyurethane Foam,

October 2007.

Jarfelt U. and Ramnas O., Thermal Conductivity of Polyurethane Foam : Best Performance, 10 th International Symposium on District

Heating and Cooling, Sept. 3-5 2006.

Yücel Aktay

R&D and Technical Support Manager

Poleks Kimya

Figure 3. Spray Polyurethane Foam Application[/caption]

Poleks Kimya produces spray foam systems ranging from 12 kg/m3 to 40 kg/m3 free rise densities for all kinds of insulation purposes and helps the applicators in selecting the right density of the spray foam.

References

Soloveva O., Solovev S., Vankov Y., Experimental Studies of the Effective Thermal Conductivity of Polyurethane Foams with Different

Morphologies, MDPI Processes 10: 2257, September 2022.

Yakushin V. And Pauliks R., Properties of Polyurethane Foam with 4th Generation Blowing Agent, e-polymers 21: 763-769, September

2021.

Carrico C., Fraga T., Carvalho V., Polyurethane Foams for Thermal Insulation Uses, MDPI Molecules 22: 1091, April 2017.

Federation of European Rigid Polyurethane Foam Associations, Thermal Insulation Materials Made of Rigid Polyurethane Foam,

October 2007.

Jarfelt U. and Ramnas O., Thermal Conductivity of Polyurethane Foam : Best Performance, 10 th International Symposium on District

Heating and Cooling, Sept. 3-5 2006.

Yücel Aktay

R&D and Technical Support Manager

Poleks Kimya