Using Composite Material at Geothermal Energy Facilities

Geothermal energy is one of the most important alternative energy sources. Diminishing resources and climate crisis in our time lead to increased use of renewable energy sources and need for such resources. Geothermal energy is a renewable, inexhaustible, and environmentfriendly energy source. Composite materials are increasingly used at geothermal energy facilities. The reason for this is the superiorities composite materials have when compared to other materials.

The word geothermal was created by union of the words geo (ground) and thermal (heat) in English. When Turkish equivalent of the word is considered, it could be considered as ground heat. The heat collected inside the earth’s crust is generally known as geothermal. The natural hot water, steam, and gas that contain various elements and other materials are known as geothermal fluid. The energy that these fluids have and created by the heat is called geothermal energy.

Geothermal fluids can vary based on their sources. The composition of fluid is affected from macro elements contained by surface and reservoir rocks they are exposed to. The most frequently found components in such fluids are Na+, K+, Ca2+, Mg2+, Cl-, SiO2, HCO3-, CO3-, SO42-, and CO2. These components create significant impact on materials used in geothermal systems. Compared to traditional tube materials these geothermal fluids are carried in, composite materials are very resilient to effects created by such components.

Due to components of geothermal fluid, there could be damage on supporting tubes such as corrosion and crustation. Such damage might cause major economic losses in geothermal energy production. Composite materials have high resistance and mechanical performance. Thus it is observed that damages form less frequently in composite supporting tubes. Particularly glass fibre composites are frequently used in geothermal energy facilities.

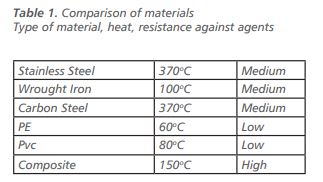

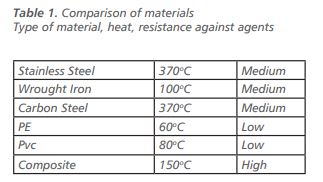

Apart from composite materials, carbon steel, stainless steel, wrought iron, pvc, and PE are used in supporting tubes. When compared to such materials, composite has the highest resistance. While fracturing and creeping might take place in other materials, composite materials are highly resistant to corrosion. Carbon steel and stainless steel can resist until 370 degrees of heat while they are not resistant against corrosion and can change form. On the other hand, composite can resist until 150 degrees of heat but does not change form.

Composite materials can prevent damage and financial losses that might take place at geothermal energy facilities. In Turkey, composite materials are used at Çeşme Geothermal Energy Facility. Studies in this facility revealed resistance of composites. Adoption of alternative and renewable sources such as geothermal energy is highly significant. Materials used at such facilities are important in terms of lifespan, resistance and sufficiency of the facility.

References

• Metin Tanoğlu - Kompozit Malzemeler ve Jeotermal Uygulamaları

• Polymer-cement composites with self-healing ability for geothermal and fossil energy applications ; M Ian Childers, Manh-Thuong Nguyen, Kenton A Rod, Phillip K Koech, Wooyong Um, Jaehun Chun, Vassiliki-Alexandra Glezakou, Diana Linn, Timothy J Roosendaal, Thomas W Wietsma, Nicolas John Huerta, Barbara G Kutchko, Carlos A Fernandez

• Metin Tanoğlu, Murat Toğulga, Gülden Gökçen - Kompozit Boruların Mekanik Özellikleri ve Jeotermal Akışkan Ortamında Dayanımının

Deneysel Analizi

Prepared by: Nilsu Kotil

The word geothermal was created by union of the words geo (ground) and thermal (heat) in English. When Turkish equivalent of the word is considered, it could be considered as ground heat. The heat collected inside the earth’s crust is generally known as geothermal. The natural hot water, steam, and gas that contain various elements and other materials are known as geothermal fluid. The energy that these fluids have and created by the heat is called geothermal energy.

Geothermal fluids can vary based on their sources. The composition of fluid is affected from macro elements contained by surface and reservoir rocks they are exposed to. The most frequently found components in such fluids are Na+, K+, Ca2+, Mg2+, Cl-, SiO2, HCO3-, CO3-, SO42-, and CO2. These components create significant impact on materials used in geothermal systems. Compared to traditional tube materials these geothermal fluids are carried in, composite materials are very resilient to effects created by such components.

The word geothermal was created by union of the words geo (ground) and thermal (heat) in English. When Turkish equivalent of the word is considered, it could be considered as ground heat. The heat collected inside the earth’s crust is generally known as geothermal. The natural hot water, steam, and gas that contain various elements and other materials are known as geothermal fluid. The energy that these fluids have and created by the heat is called geothermal energy.

Geothermal fluids can vary based on their sources. The composition of fluid is affected from macro elements contained by surface and reservoir rocks they are exposed to. The most frequently found components in such fluids are Na+, K+, Ca2+, Mg2+, Cl-, SiO2, HCO3-, CO3-, SO42-, and CO2. These components create significant impact on materials used in geothermal systems. Compared to traditional tube materials these geothermal fluids are carried in, composite materials are very resilient to effects created by such components.

Due to components of geothermal fluid, there could be damage on supporting tubes such as corrosion and crustation. Such damage might cause major economic losses in geothermal energy production. Composite materials have high resistance and mechanical performance. Thus it is observed that damages form less frequently in composite supporting tubes. Particularly glass fibre composites are frequently used in geothermal energy facilities.

Apart from composite materials, carbon steel, stainless steel, wrought iron, pvc, and PE are used in supporting tubes. When compared to such materials, composite has the highest resistance. While fracturing and creeping might take place in other materials, composite materials are highly resistant to corrosion. Carbon steel and stainless steel can resist until 370 degrees of heat while they are not resistant against corrosion and can change form. On the other hand, composite can resist until 150 degrees of heat but does not change form.

Due to components of geothermal fluid, there could be damage on supporting tubes such as corrosion and crustation. Such damage might cause major economic losses in geothermal energy production. Composite materials have high resistance and mechanical performance. Thus it is observed that damages form less frequently in composite supporting tubes. Particularly glass fibre composites are frequently used in geothermal energy facilities.

Apart from composite materials, carbon steel, stainless steel, wrought iron, pvc, and PE are used in supporting tubes. When compared to such materials, composite has the highest resistance. While fracturing and creeping might take place in other materials, composite materials are highly resistant to corrosion. Carbon steel and stainless steel can resist until 370 degrees of heat while they are not resistant against corrosion and can change form. On the other hand, composite can resist until 150 degrees of heat but does not change form.

Composite materials can prevent damage and financial losses that might take place at geothermal energy facilities. In Turkey, composite materials are used at Çeşme Geothermal Energy Facility. Studies in this facility revealed resistance of composites. Adoption of alternative and renewable sources such as geothermal energy is highly significant. Materials used at such facilities are important in terms of lifespan, resistance and sufficiency of the facility.

Composite materials can prevent damage and financial losses that might take place at geothermal energy facilities. In Turkey, composite materials are used at Çeşme Geothermal Energy Facility. Studies in this facility revealed resistance of composites. Adoption of alternative and renewable sources such as geothermal energy is highly significant. Materials used at such facilities are important in terms of lifespan, resistance and sufficiency of the facility.