We had a pleasant conversation with Mr. Emrah Şenol, Managing Director of Netzsch Turkey. Emrah Şenol shared valuable information with our readers about the organization and services of Netzsch in Turkey. Enjoyable reading…

Could you please tell our readers about yourself and your professional background?

After graduating from DEU Mechanical Engineering Department in 2009, I started my professional career by adding MBA education at Ege University.

I worked in the technical sales departments of companies operating in different sectors such as energy, sheet metal production and air conditioning. Afterwards, I have been transferred to our company during the establishment of Netzsch Turkey.

Could you please share with our readers the story of Netzsch’s founding and the development process of its organization in Turkey?

Netzsch is a company that was founded approximately 150 years ago in Selb, Germany, a region famous for porcelain production.

Although it has been working more intensively on the ceramic industry since its location in the beginning, it continues its global activities with approximately 5000 employees by focusing on 3 main business units as “Analyzing and Testing”, “Pumps and Systems” and “Grinding and Dispersing” with the growth by years.

Netzsch Turkey, on the other hand, was established in Izmir in 2013 under the “Grinding and Dispersion” business unit and serves Turkey and the surrounding markets.

Could you please tell us about the sectors and product groups you serve?

We serve to many different sectors such as energy, chemistry, mining, cement, food, pharmaceuticals and cosmetics. In fact, there is an application that we address to all items we use in our daily lives, from mobile phones to disinfectants, from the coffee we

drink to the t-shirts we wear.

In our grinding and dispersing business unit, we offer machinery and plant productions for Dry and Wet Grinding, Classification, Mixing, Homogenization processes.

As Netzsch Turkey, we provide technical sales, engineering, service and sales of spare parts and grinding beads from stock from our Izmir center for the processes I mentioned. We are as well as a supply center for our global projects.

What kind of work do you do to improve the service you offer in order to serve your customers better? Could you convey your R&D activities?

Since we operate in a wide variety of sectors, we are a company that constantly learns from the needs of the market and offers solutions for the needs. For example, we can apply a technological development we have achieved in wet grinding technologies to dry

grinding technologies.

Or we can update a dry grinding and classifiying process of industrial minerals, when we know the specific need of any end product on the cosmetic sector. Therefore, I can say that there is an R&D study in every project we work on.

Are there any new products that you plan to present to the sector as a result of your studies?

I can say that our Pamir mill, which we introduced recently, has made an important difference in dry grinding technologies. We can create serious advantages in production costs by providing high energy efficiency in micronized dry grinding of industrial raw materials such as calcite, talc and barite used in the paint industry.

Also we offer higher color intensity, less waste, high energy efficiency and sustainable production with our Neos mills, which are also used for grinding of paints.

How do you evaluate the development of the paint industry in Turkey? What is the importance of the Turkish market in the world?

As you know, we are the 5th largest paint producer country in Europe. Due to our position, our paint industry has to grow by constantly competing with manufacturers in Europe, especially on the basis of quality.

In addition to the increasing technological infrastructure investments required by this competition, we observe that the orientation towards products with high added value is increasing with the R&D activities carried out.

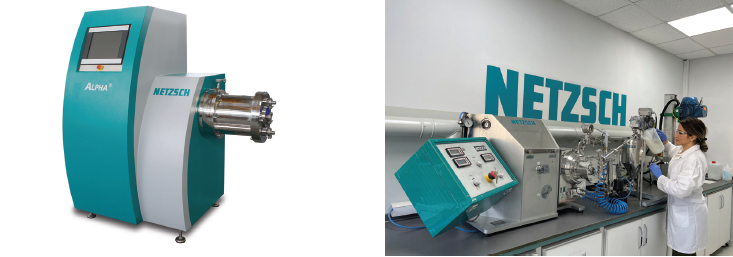

Due to our belief in this potential and the development in the sector, we, as Netzsch, offer to our customers with our grinding laboratory investment in Izmir location a scalable process support for their R&D studies and production processes.

Sustainability has become more and more important with the climate crisis in the world and the depletion of resources. As Netzsch, what are your studies on sustainability?

As Netzsch, we are a company that believes in continuous improvement and our main goal in all the technologies we develop and offer is high energy efficiency and sustainability. For example, with our last developed mill, Pamir, we ultimately create an environmental advantage by having 30% less energy consumption compared to existing dry grinding processes of industrial minerals; which is the main expense item of our customers, per

ton of production. Again, with our Neos high-performance wet grinding mills, we offer advantages on paint production processes such as energy, time and less pollution

by offering up to 10 times higher performance.

We have gone through a long pandemic period and the effects of the pandemic still continue. How did this period affect your company and what precautions did you take?

At the beginning, like all companies, we had no idea how the pandemic would progress, how big it would be and how it would affect our business life. However, since we have a dynamic and flexible team that can use any place where there is phone and internet access

as an office, we managed to grow out of the process.

Again, like many of our customers, as Netzsch Turkey, we have also managed to increase our exports by turning the crisis in global supply chains into an opportunity during the pandemic process.