Antibacterial Coatings

Bacterias are micron-scale protistans encountered usually in refrigerators, washing machines, carpets, ceramic

surfaces etc., in our daily lives. Pathogenic microorganisms

form a biofilm layer on the surfaces where they are colonized.

This situation causes very serious clinical infections in humans. On the other hand, the resistance of pathogenic microorganisms to antibiotics prevents the treatment of microbial infections.

Microbial contamination is one of the most important problems in medical devices, health services, application areas where hygiene is required, hospital and dental surgery

instruments, water treatment systems, air conditioners, ventilation systems, food packaging and food storage and textile materials [Hos].

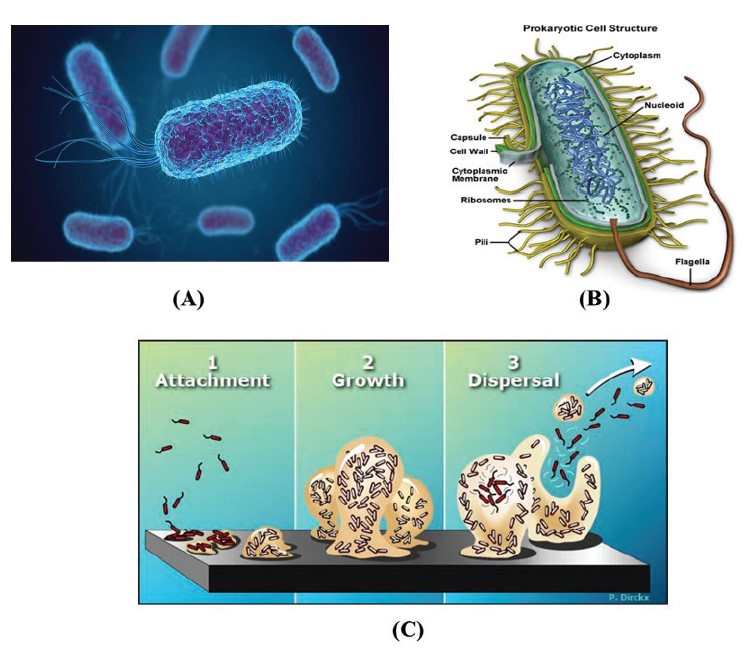

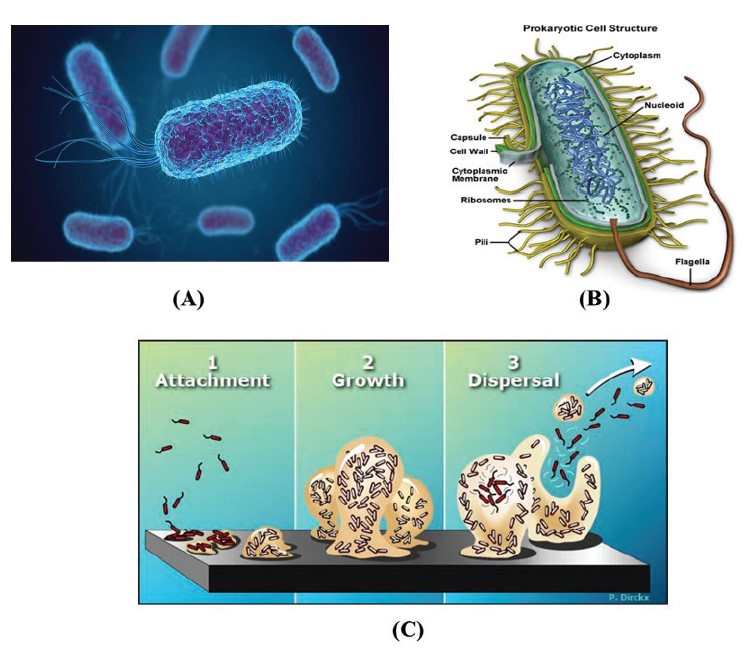

[caption id="attachment_149991" align="aligncenter" width="756"]

Figure 1. A) A bacteria example B) Schematic representation of the structure of bacteria C) Schematic representation of

biofilm formation.[/caption]

Nosocomial infections are infections that do not occur in the incubation period when the patient is admitted to the hospital or that occur after discharge. It mostly develops 48-72 hours after the patient’s hospitalization and within 10 days of discharge.

The reason for the occurrence of these infections is 4%-10% (this rate reaches 30% in intensive care units) due to bacterial colonization on biomedical surfaces. According to 2011 data, an estimated 722,000 nosocomial infections occurred in the United States.

75,000 of this number resulted in death [Clotuier et al., Mgill et al.]. Textile materials have very convenient environments for the growth of microorganisms and microorganisms can

live on textile surfaces for months. On the one hand, microorganisms cause changes in the properties of textile materials (loss of strength, smell, color change) and on the other

hand, they negatively affect the person who uses them.

As a result of a clinical study, it was found that 65% of nurses caring for MRSA infected patients had MRSA pathogen in their gowns [Boryo]. In recent years, the development of

antibacterial coatings has become a fairly active field of work for the solution of these problems.

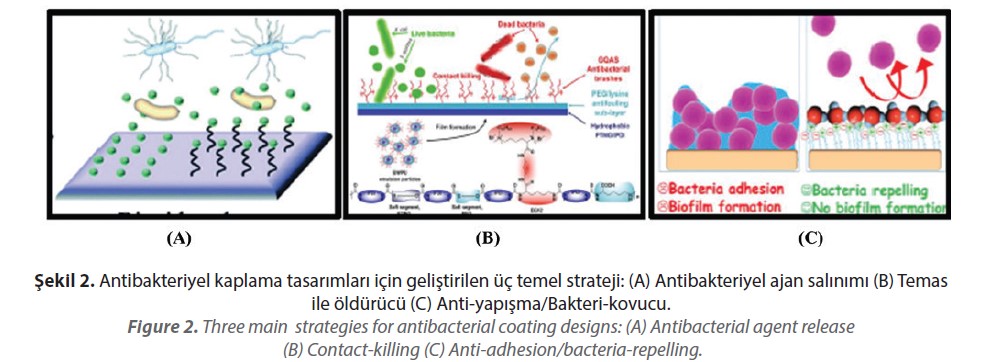

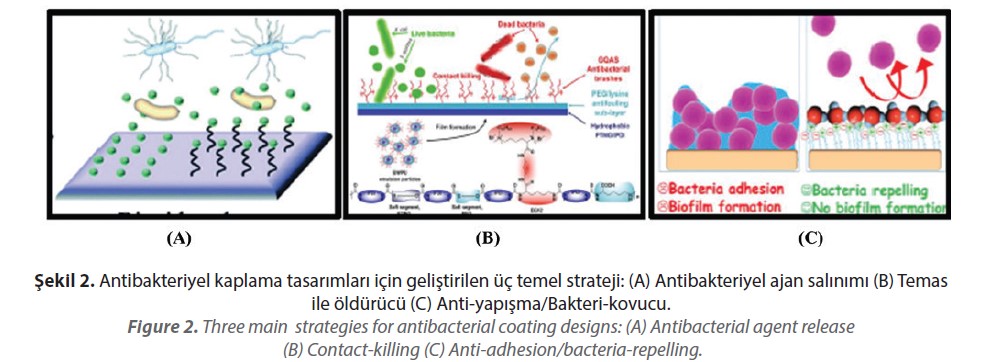

There are three major strategies for designing antibacterial coatings: antibacterial agent release, contact-killing, and anti-adhesion/ bacteria-repelling. In antibacterial agent release coatings (release based coatings), coatings exert their antibacterial activity by leaching

loaded antibacterial compounds over time.

This situation allows killing of both adhered and adjacent planktonic bacteria. The release of incorporated antibacterial agents is achieved by diffusion into the aqueous medium, erosion/ degradation, or hydrolysis of covalent bonds.

The most commonly used antibacterial compounds are: antibiotics (aminoglycosides, quinolones, penicillins, glycopepites, etc.), antimicrobial peptides, elements (silver, copper, zinc, gallium, selenium, halogens), enzymes (lysosome, acylase) and organic cationic compounds [quaternary ammonium compounds (QAC), chlorhexidine, octenidine, chitosan].

In contact-killing approach, antimicrobial compounds are covalently anchored to the material surface by flexible, hydrophobic polymeric chains. It is believed that the adhering bacterium dies because the compound to which it is attached damages the cell membrane.

Cationic compounds or enzymes, such as chitosan, are preferred in use. In Anti adhesion/Bacteria-repelling approach mainly uses mechanisms that prevent early biofilm formation without killing microorganisms on the surface. In other words, coatings seek to prevent the earliest step of biofilm formation using non-cytotoxic mechanisms.

Bacterial adhesion at biomaterial surfaces is generally described using a twostage model.The first stage is an initial, rapid and reversible stage (stage I), mediated by non-specific physicochemical interactions.

The second stage is the ‘locking’ stage (stage II), which involves species-specific bacterial adhesion proteins. Materials such as PEG, oxazolin, nitrooxide radicals, chlorinated plasma polymers are shown as examples [Cloutier el al.].

Products with antibacterial properties are generally produced from metal, ceramic, polymer and composite materials. These products can be prepared by basically two different

methods. First of all, the entire product is produced from antibacterial material.

In this method, the high cost depending on the material and composition used makes

the method disadvantageous. For this reason, it is more advantageous to apply antibacterial coatings on the ready surface, which is the second method.

Dip coating, spraying, chemical vapor deposition (CVD), physical vapor deposition

(PVD), sol-gel, electrophoretic deposition and strip casting techniques are commony used for coating. It is possible to give the surface the desired properties by functionalizing

the surface or applying different techniques such as etching or implantation, plasma processes apart from coating applications.

The basis of antibacterial coatings is aimed to protect human health and can be easily

obtained depending on the application place and purpose. The studies on antibacterial coatings are increasing day by day. The necessity of increasing the stability of the coatings

and the inadequacy of the clinical studies of the coatings are seen as aspects that need to be improved.

References

• Hoş. A., Antibakteriyel Polikaprolakton-hidroksiapatit Kompozit Filmlerin Üretimi, Sakarya

Üniversitesi Fen Bilimleri Enstitüsü, 2016.

• M. Cloutier, D. Mantovani, F. Rosei., 2015, Antibacterial Coatings: Challenges, Perspectives,

and OpportunitiesTrends in Biotechnology, 33, 1, 637.

• Magill, S.S. et al. 2014, Multistate point-prevalence survey of health care-associated

infections. N. Engl. J. Med. 370, 1198–1208

• Boryo, D. 2013, The Effect of Microbes on Textile Material: A Review on the Way-Out So

Far, The International Journal Of Engineering And Science, 2319, 1805.

• Lichter, J.A. et al. 2009, Design of antibacterial surfaces and interfaces: polyelectrolyte

multilayers as a multifunctional platform. Macromolecules 42, 8573–8586

• https://www.chemistryworld.com/news/giant-long-lived-bacteria-could-makemicrobial-

farms-more-productive/4011137.article

• https://micro.magnet.fsu.edu/cells/bacteriacell.html

• https://www.cs.montana.edu/webworks/projects/stevesbook/contents/chapters/

chapter001/section002/black/page001.html

• https://www.tucsa.org/images/sss/ÇELİK%20YÜZEYLERİN%20MİKROPLARDAN%20

KORUNMASI%20DEZENFEKSİYON,%20DEZENFEKTALAR,%20ANTİMİKROBİYAL%20BOYALAR%

20ve%20KAPLAMALAR.pdf

• https://www.ideaport.org.tr/img/blog/61d2a730db781.pdf

Assoc. Prof. Dr. Ekrem Altuncu

TÜYİDER (Surface Treatments Association of Turkey) Scientific and Advisory Board Member

Sakarya University of Applied Sciences

Material and Production Technologies Application and Research Center- SUMAR Manager

Dr. Nilay Tüccar Kılıç

Sakarya University of Applied Sciences

Material and Production Technologies Application and Research Center

Figure 1. A) A bacteria example B) Schematic representation of the structure of bacteria C) Schematic representation of

Figure 1. A) A bacteria example B) Schematic representation of the structure of bacteria C) Schematic representation of Products with antibacterial properties are generally produced from metal, ceramic, polymer and composite materials. These products can be prepared by basically two different

methods. First of all, the entire product is produced from antibacterial material.

In this method, the high cost depending on the material and composition used makes

the method disadvantageous. For this reason, it is more advantageous to apply antibacterial coatings on the ready surface, which is the second method.

Dip coating, spraying, chemical vapor deposition (CVD), physical vapor deposition

(PVD), sol-gel, electrophoretic deposition and strip casting techniques are commony used for coating. It is possible to give the surface the desired properties by functionalizing

the surface or applying different techniques such as etching or implantation, plasma processes apart from coating applications.

The basis of antibacterial coatings is aimed to protect human health and can be easily

obtained depending on the application place and purpose. The studies on antibacterial coatings are increasing day by day. The necessity of increasing the stability of the coatings

and the inadequacy of the clinical studies of the coatings are seen as aspects that need to be improved.

References

• Hoş. A., Antibakteriyel Polikaprolakton-hidroksiapatit Kompozit Filmlerin Üretimi, Sakarya

Üniversitesi Fen Bilimleri Enstitüsü, 2016.

• M. Cloutier, D. Mantovani, F. Rosei., 2015, Antibacterial Coatings: Challenges, Perspectives,

and OpportunitiesTrends in Biotechnology, 33, 1, 637.

• Magill, S.S. et al. 2014, Multistate point-prevalence survey of health care-associated

infections. N. Engl. J. Med. 370, 1198–1208

• Boryo, D. 2013, The Effect of Microbes on Textile Material: A Review on the Way-Out So

Far, The International Journal Of Engineering And Science, 2319, 1805.

• Lichter, J.A. et al. 2009, Design of antibacterial surfaces and interfaces: polyelectrolyte

multilayers as a multifunctional platform. Macromolecules 42, 8573–8586

• https://www.chemistryworld.com/news/giant-long-lived-bacteria-could-makemicrobial-

farms-more-productive/4011137.article

• https://micro.magnet.fsu.edu/cells/bacteriacell.html

• https://www.cs.montana.edu/webworks/projects/stevesbook/contents/chapters/

chapter001/section002/black/page001.html

• https://www.tucsa.org/images/sss/ÇELİK%20YÜZEYLERİN%20MİKROPLARDAN%20

KORUNMASI%20DEZENFEKSİYON,%20DEZENFEKTALAR,%20ANTİMİKROBİYAL%20BOYALAR%

20ve%20KAPLAMALAR.pdf

• https://www.ideaport.org.tr/img/blog/61d2a730db781.pdf

Assoc. Prof. Dr. Ekrem Altuncu

TÜYİDER (Surface Treatments Association of Turkey) Scientific and Advisory Board Member

Sakarya University of Applied Sciences

Material and Production Technologies Application and Research Center- SUMAR Manager

Dr. Nilay Tüccar Kılıç

Sakarya University of Applied Sciences

Material and Production Technologies Application and Research Center

Products with antibacterial properties are generally produced from metal, ceramic, polymer and composite materials. These products can be prepared by basically two different

methods. First of all, the entire product is produced from antibacterial material.

In this method, the high cost depending on the material and composition used makes

the method disadvantageous. For this reason, it is more advantageous to apply antibacterial coatings on the ready surface, which is the second method.

Dip coating, spraying, chemical vapor deposition (CVD), physical vapor deposition

(PVD), sol-gel, electrophoretic deposition and strip casting techniques are commony used for coating. It is possible to give the surface the desired properties by functionalizing

the surface or applying different techniques such as etching or implantation, plasma processes apart from coating applications.

The basis of antibacterial coatings is aimed to protect human health and can be easily

obtained depending on the application place and purpose. The studies on antibacterial coatings are increasing day by day. The necessity of increasing the stability of the coatings

and the inadequacy of the clinical studies of the coatings are seen as aspects that need to be improved.

References

• Hoş. A., Antibakteriyel Polikaprolakton-hidroksiapatit Kompozit Filmlerin Üretimi, Sakarya

Üniversitesi Fen Bilimleri Enstitüsü, 2016.

• M. Cloutier, D. Mantovani, F. Rosei., 2015, Antibacterial Coatings: Challenges, Perspectives,

and OpportunitiesTrends in Biotechnology, 33, 1, 637.

• Magill, S.S. et al. 2014, Multistate point-prevalence survey of health care-associated

infections. N. Engl. J. Med. 370, 1198–1208

• Boryo, D. 2013, The Effect of Microbes on Textile Material: A Review on the Way-Out So

Far, The International Journal Of Engineering And Science, 2319, 1805.

• Lichter, J.A. et al. 2009, Design of antibacterial surfaces and interfaces: polyelectrolyte

multilayers as a multifunctional platform. Macromolecules 42, 8573–8586

• https://www.chemistryworld.com/news/giant-long-lived-bacteria-could-makemicrobial-

farms-more-productive/4011137.article

• https://micro.magnet.fsu.edu/cells/bacteriacell.html

• https://www.cs.montana.edu/webworks/projects/stevesbook/contents/chapters/

chapter001/section002/black/page001.html

• https://www.tucsa.org/images/sss/ÇELİK%20YÜZEYLERİN%20MİKROPLARDAN%20

KORUNMASI%20DEZENFEKSİYON,%20DEZENFEKTALAR,%20ANTİMİKROBİYAL%20BOYALAR%

20ve%20KAPLAMALAR.pdf

• https://www.ideaport.org.tr/img/blog/61d2a730db781.pdf

Assoc. Prof. Dr. Ekrem Altuncu

TÜYİDER (Surface Treatments Association of Turkey) Scientific and Advisory Board Member

Sakarya University of Applied Sciences

Material and Production Technologies Application and Research Center- SUMAR Manager

Dr. Nilay Tüccar Kılıç

Sakarya University of Applied Sciences

Material and Production Technologies Application and Research Center