At 26.9.2019, 13:59:24, an earthquake happened at Istanbul Silivri offshore (Marmara Sea), with a magnitude of 5.7 and depth of 11.9 km. This earthquake which the biggest after the Marmara Earthquake in 1999, has turned our eyes on us to check the places we live again.

Why Marmara Earthquake, Istanbul is so important? I visit many cities of our country because of our business. During these visits, I always hear complaints like “Everything is done in Istanbul, what is so special about there?”

Although my family is from Elazığ city, we have been living in Istanbul for almost 80 years. We are Istanbul citizens.

According to the 2017 Annual Report of the Revenue Administration, tax liabilities amounting to TL 760,214 billion were accrued throughout the country last year, including those transferred from previous years. 625,512 billion TL of this amount was collected.

For Istanbul; accrual: 326,234 billion TL, collection: 275.34 billion TL, collection rate: 84.40 percent, the rate of Istanbul’s total accrual was 44.4 percent. For this reason, Istanbul is extremely important.

However, Istanbul receives less amount according to this tax rate. In this case, it can be said that the investments made in Istanbul are even low. Technically, Istanbul’s growth is not so accurate. If the Marmara earthquake occurs above 7 and more magnitude, loss of life and property will be too much.

There is a serious risk for our country. Horizontal construction should be started immediately and İstanbul’s expansion should be provided starting from neighboring provinces. It is the iron and concrete that determines the skeleton of a reinforced concrete structure.

The producers of iron are known and can be inspected before entering the mold. However, ready-mixed concrete is not. Because it’s not actually ready. It is prepared and shipped upon order. If so, the concrete should be kept under very good control from its fresh state to its hardened state.

There are enough laws, standards, regulations on the design of concrete. Ready-mixed concrete facilities are highly developed and the margin of error in machine production is minimized.

Despite this, there are a total of 8 components exist, such as cement, water, aggregate [sand, stone dust, crushed stone 1 (5-12), crushed stone 2 (12-20)], chemical additive, mineral additive.

Because human factor is involved in every stage, unfortunately control of the concrete cannot be done. People who make ready-mixed concrete and people who place it in the mold are different.

Like in developed countries abroad – some in Turkey also- readymixed concrete producers should place the concrete that they produce into the mold and cure it. Therefore, the human factors will be removed.

Subcontractors should establish an organization under the ready-mix concrete company. This situation is expected to become more widespread in the future.

Revisions have been made in the building supervision law. Accordingly, inspection of chip concrete samples for concrete laboratories has become necessary and is required. It is an extremely appropriate decision.

However, the design of the fresh concrete does not end with the perfect design and the replacement and maintenance processes must be provided on-site within the required standards.

Even though if excellent standards, regulations are on force, unfortunately there are problems at implementation; such as bad intentions, getting away with the consequences, economically and politically influential people who benefits from the situation. This situation affects the basic income distribution negatively.

Only morality, social self-control and laws can solve the problem. 2019 was declared as ’pedestrian priority traffic year‘ . According to the law, vehicles must give way to pedestrians. Social responsibility and awareness should spread.

For example; when a vehicle driver on the front allows the citizen to cross the pedestrian crossing, the rear vehicle driver should take his own measures. He/she must adjust the braking distance accordingly, do not honk the horn and behave badly.

The pedestrian also should cross only from where the pedestrian crossing exist, and should not cross the middle of the road, jumping through the relief.

Providing conscious social autocontrol will enable us to become even more civilized in cleaning, health, education and human relations. After these anecdotes, let’s examine “What We Can Do?” for our structures.

A-) Concrete Cover

A-) Concrete Cover

Most of the buildings in our country are reinforced concrete. The durability of reinforced concrete depends on the iron in it. In other words, if the reinforcement inside a concrete building is damaged due to corrosion and loses its continuity, the structure collapses.

The better the concrete surrounds the iron, the longer the life of the structure. Unfortunately, to save the net area (m2) in the buildings, even the rust allowance was reduced. Therefore, some accessories became vulnerable to corrosion. Also, to save space, these surfaces were not plastered.

Gypsums were cast directly on it. Corrosion has also started to occur in new buildings as a result of the direct contact of gypsum with concrete. Although sometimes a concrete primer is applied before the gypsum, a homogeneous application is not made everywhere.

In fact, even on many surfaces other than the ceiling flooring, even concrete primer is not used. Even if costs are involved, the cost of a lost live is invaluable. Therefore, the structure formwork system should be reviewed. Deformed molds from excessive use should not be used.

The type of release agent must be observed. In short, the rust allowance must be placed and the variety should be increased. There are many examples of covers abroad. Using only plastic covers may be insufficient.

B-) Adjacent Structures

In some adjacent buildings, no spaces were left between the buildings. As a result of the oscillations during the earthquake, both reinforced concrete frames strike each other with full speed. Structural cracks occur as a result of the impact. Another drawback is the occurrence of waterproofing problems.

Initially, zero or just 1-2 cm separations, can later be observed as reaching up 5-15 cm after an earthquake. The water entering the building -from both the building facade and the attic- has a negative impact on the comfort of life. Water ingress causes spills in uygugypsum, blistering in paint and corrosion in the structure.

As known from various researches, quantity of diseases such as COPD, asthma and bronchitis has increased. As if there is a dilatation gap in the structure, such places must be repaired with bitumen-polyurethane based products.

The inside of these gaps should not be filled with rigid, cement based products. Because the rigid material will crack as a result of the movements during the earthquake.

*Note: The screed application specified in article 9 in graphic, is valid for horizontal planes. On vertical surfaces, closure should be considered with heat mantle and so on.

C-) Basement Floors

It is necessary to mention the closed car parks and basements again. The height of the basement of the building should not exceed, floor height / building height = 1/6. So if the height of the basement floor is 3 mt. than the height of the building should not exceed 18 meters.

This rule can be violated if the required reinforcement and concrete quality is correctly selected during the design phase. The basement floors are usually ignored, as the floor owners do not directly see them. The pergola to be made to the garden, the color of the exterior paint, or the tree to be planted, sometimes leads to greater controversy.

“Even if we put our heads under the ground like an ostrich, the structure exists”. Iron reinforcement of reinforced concrete surfaces should not be left open. Some places are not plastered, only lime or gypsum is applied. This is extremely dangerous.

Even if there is no corrosion in the environment, it initiates corrosion and increases its speed. If there is a crack in the reinforced concrete, it should be monitored whether it is progressing or not. If it is covered, it becomes impossible to detect. Proper waterproofing must be done from the positive side.

In separate basement floors, insulation should be made by opening the perimeter of the building. However, this application is not done because it is costly. Basement floors are statically important. If possible, water insulation should be done from outside and not from inside. Internal waterproofing is not very accurate.

Because even if you prevent water from entering the structure, you cannot stop the corrosion of iron. As shown in the photo, a small head trench was constructed so that water could not spread and be directed. However, these methods will not prevent the melting of iron in the concrete due to corrosion.

The pan method shown in the photo on the right is a system that is used frequently. Here you can collect the water to a certain place and channel it from there, but you cannot prevent corrosion in the iron.

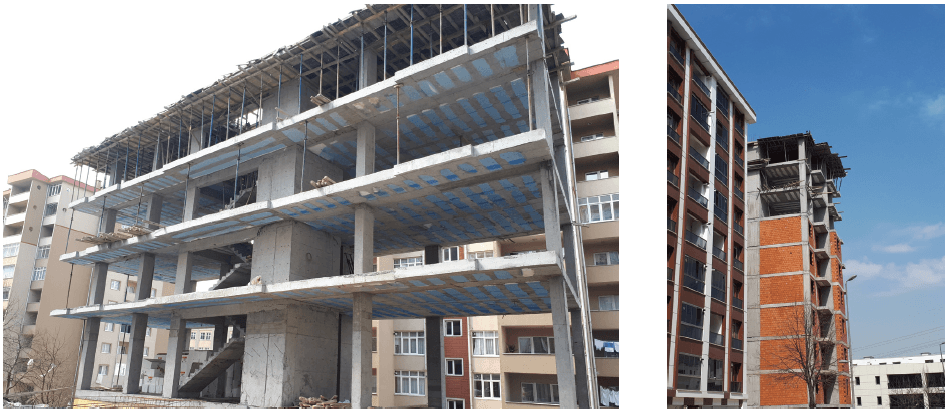

D-) Asmolene Flooring

No public building (generally) is made using asmolene foam. In order to finish the job quicker, private sector uses asmolene foam even for multi-storey buildings. The foams used are also very sensitive to temperature as there is no density.

Some of the problems that arise in constructing structures using asmolene foam are as follows;

1) It is not suitable for use in earthquake zones as the frame is not fully formed.

2) It should not be used without reinforced concrete shear wall.

3) Due to the low rigidity of these beams, horizontal displacement between floors increases greatly and transmits very large second order moments to the columns.

4) The heated air expands and rises. Due to the contact surface of the heated air, the foam also produces harmful gases. 5) During fire, these foams will immediately catch fire and proceed.

6) Because of oscillation from earthquake etc., the ceiling plaster can fall down Sometimes even the foam is dislodged and falls down. If there are children, injuries and material damages can be seen.

Asmolen Flooring Examples

Since 2018, earthquake regulations (Turkey Earthquake Building Regulations-TBDY) has changed. Dr. Mehmet Nuray Aydınoğlu , from Boğaziçi University Kandilli Observatory and Earthquake Research Institute, commented on the limitations imposed on the load-bearing asmolen flooring system, these comments should be read from according sources.

In the concluding section, Dr. Mehmet Nuray Aydınoğlu stated that, in DTS (Earthquake Design Class) = 1,2 and NMS (Building Height Class) ≥ 6 asmolene pavement buildings, load bearing walls in both directions, should provide the condition of the tipping torque stated in section 4.3.4.6 Equ. (4.3).

Otherwise, asmolene flooring systems (see Table 3.3 for definition of NMS), • (a) Cannot be used for buildings with DTS = 1,2 and NMS ≥ 6 (Hn, max = 17.5 m), • (b) Can be used for buildings with DTS = 3,4 and NMS ≥ 7 (Hn, max = 17.5 m).

In Conclusion

The above topics can be reproduced by giving many more examples. According to the researches, a building without water insulation loses 66% of its carrying capacity after 10 years. Thus, a 80×60 cm. column which can carry 100 tons of load at the beginning, can only carry a load of 34 tons if no water isolation is applied.

If so, a solution should be sought for apartments and sites, in accordance with empathy and social understanding. When the earthquake arrives, the situation on the 1st floor, is the same as on the 8th floor. The damage status of the structure and its oscillations during the earthquake may be different, depending on the storey.

However, at the time of the earthquake psychology and fear is the same. All residents, at the ground floor or the top floor of the building, must deal with the problems of the building. Waterproofing, corrosion, cracking and damage in concrete are common problems of all the floors’ owners.