In this new century which we have left the decade behind, a new economic developmenthas begun to emerge, especially in the developed countries and especially in the world, in the services sector. With the effect of globalization, the economies of the country have increasingly started to integrate with the outside world.

When we look at the production dimension, the elements that create difference and value (design, creativity, technology that increases the comfort and safety of the end user, brand value, image value, etc.) have come to the forefront rather than production in developed countries.

In the light of these developments, the concept of engineering started to change in this new century. Now, in the classical sense, engineers have become more interested in other aspects of the work (R&D, technology, creativity, design, etc.) in this century than in the production department.

Technological and industrial developments in this century have naturally increased the commitment to basic resources such as energy and raw materials, and it is becoming more and more important to use these resources in the most efficient way.

Therefore, because of constantly developing and changing work and working conditions, engineers and manufacturers have started to have too many tasks at this point.

In recent years, when we look at successful engineers or businesspeople working in production systems, we see that people who manage scarce resources, propose alternative production policies and provide interdisciplinary coordination in projects are becoming more prominent.

In this context, human, machinery, materials and similar elements; for the examination, planning, organization, execution, supervision and development of systems in the industrial and service sectors;

Companies with an engineering infrastructure based on preventing and solving problems by developing systems, models and methods are the ones that can achieve success or will catch up in the near future.

With the advent of the 21st century;

Especially industrial engineers working today are trying to adapt to the developments in production operations. Mostly, they strive to adopt these changes in order to ensure advanced, efficient and continuous development in the manufacturing environment.

In short, the fundamental task that industrial engineers have to do in this period is to formulate, implement and implement the required strategies in the most appropriate way by taking into consideration the changes that they face. Now we live in such a world that we encounter many changes in different dimensions at unexpected times.

In this age, industrial engineering has changed rapidly with the core technological elements and has become a more attractive engineering discipline for the new generation.

Society is becoming an information society and the concept of innovation is becoming more and more important. Accordingly, the continuous improvement of industrial culture and manufacturing has become an important element in the economic development of nations.

Another noteworthy issue in this age is the existing competitive environment, which naturally gives more impetus to technological advances. Manufacturing has now entered a new era and global markets have begun to emerge.

As a result, manufacturing organizations had to make radical structural changes in order to survive and compete.

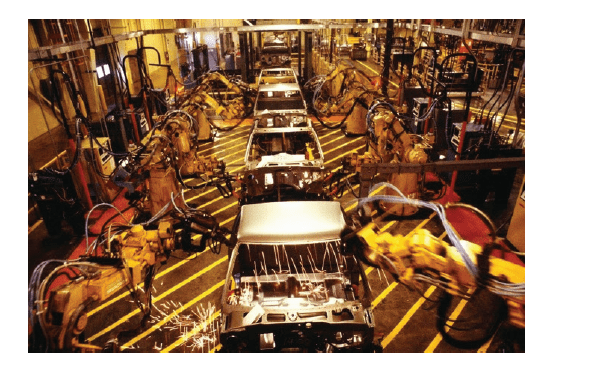

The emergence of new manufacturing technologies has combined systems, intelligence and integration, and the manufacturing system has become extremely complex. As a result, a problem occurring in a small regional part of a system affects the entire system more complexly.

Engineers now have to use advanced techniques such as modeling, simulation, and optimization to ensure the structure, organization and management of a manufacturing system. Similarly, there is a need to develop new people-oriented systems to ensure the structure,

organization and management of a manufacturing system;

New ideas have emerged in design, processes and management specific to modern manufacturing. This is due to developments in system theories and methods that constantly affect each component of a manufacturing system.

This naturally leads to a better understanding of the material, energy and information flows in a manufacturing system. As a result, these developments have led to further developments in theories and methods.

In the meantime, with the increasing consumer power along with economic development, consumption and consumer market structure has caused great changes. The world has entered an age of product diversity, individualized production, systematization and internationalization.

It has entered an even more difficult period in terms of competition and companies are now able to develop product, R&D, after-sales service and so on. they had to focus more on the activities. Meanwhile, classical theories of organization and management have changed drastically.

As a result, the customer- specific idea of mass production has evolved, which, of course, necessitates the application of new approaches in manufacturing. Due to the increasing momentum in the development of science, technology and markets, companies had to make very urgent changes.

New generation technologies, information and products have started to replace the old ones at an unpredictable speed. This has further increased the demand for technology use and has also brought about changes in resource efficiency and environmental protection.

Meanwhile, modern technology has been introduced not only to ensure high efficiency and cost effectiveness, but also to help achieve clean production and continuous change. In this information age, information technologies and related technologies,

advanced manufacturing technologies and methods (rapid manufacturing, lean manufacturing, flexible manufacturing, visual manufacturing, green manufacturing) are changing rapidly. The techniques applied for high speed, high efficiency, high quality and low production loss were naturally affected by these developments.

In the 21st century, in parallel with these changes in the world;

it has become very important which engineering strategies should be developed and implemented. Within this framework, there are many strategies to be considered as follows:

In my opinion, the strategies that need to be observed and implemented are as follows;

1- Developing the necessary engineering theories, methods and applied research by considering the developments in the production environment and emerging technologies,

2- Develop advanced manufacturing methods and management research to keep pace with changes in the market and scientific developments,

3- Focusing on issues such as clean production, continuous development, theories, methods and applied research, considering the conditions of our country,

4- To make researches on issues such as work study and analysis and to make efforts to increase the production efficiency of organizations and production workers in our country,

5- To improve the ability of the people in charge of manufacturing management to produce quality output and to develop business study and analysis systems for this purpose, to adopt and apply intelligent manufacturing, manufacturing system engineering and other emerging technologies,

6- Improve the integration of information, materials and energy flow to improve the efficiency of production operations,

7- To defend the importance of human factor in managerial thinking, management ideas, management theories and researches about management techniques.

T. Emrah Sözer – Industrial Engineer – Production Director – Sözer Makina Sanayi ve Ticaret Ltd. Şti