The MA-T family of multi-angle spectrophotometers coupled with EFX QC software enables accurate evaluation and verification of color, sparkle, and coarseness characteristics for effect finishes. It enables users across an entire supply chain to measure new dimensions of color with more precision than ever before possible.

EFX QC cloud-based software simplifies the process of communicating tolerances and measurement methods across supply chains. New visual tools enable real-time performance monitoring and deliver actionable insights for troubleshooting to reduce downtime, waste, and rework.

MA-T Family

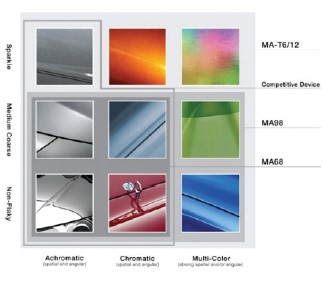

The MA-T family combines color imaging with multi-angle measurement to deliver the most reliable characterization of color, sparkle, and coarseness. It provides to measure colored sparkle and coarsness in special effect pigments.

Multi-angle spectrophotometers in market couldn’t measure these effects until today. Users can specify and measure effect finishes across a variety of applications, from automotive paint to plastics and metals, with greater repeatability and reproducibility than ever before.

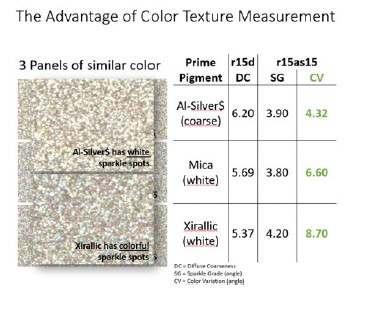

MA-T devices deliver 98% measurement reproducibility—up from 80% in previous devices—to provide the most reliable analysis of colored sparkle and coarseness available in the market. Precise readings deliver 2.5X the repeatability and 2X the reproducibility of any other multi-angle device on the market.

These comprehensive readings are processed by EFX QC software, using X-Rite’s groundbreaking uniform texture scale, to digitize materials and establish tolerances that are not dependent on visual impressions of sparkle or coarseness.

Improved characterization of color, sparkle, and coarseness enables versatility across materials, allowing operators to validate that neighboring parts made from different materials will properly match at final assembly.

What it Means to Measure Texture? Why Measure Texture?

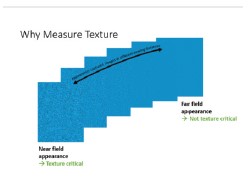

Certain special effects parameters—specifically sparkle and coarseness— show different characteristics depending on the distance of the viewer. While standing far away from the colored surface, viewers are more likely to notice the averaged color and reflections of light.

Upon closer observation, the granular reflections of sparkle and coarseness become more evident and change the appearance of the color. The best way to achieve accurate coloration in close-up viewing is to account for the sparkle and coarseness that gives a color its character.

Having the ability to measure texture allows color specialists to achieve their intended color when viewed from any distance—and especially when viewing close-up.

What Makes Texture Measurement Possible?

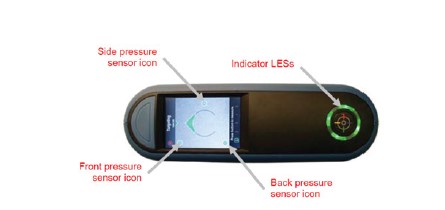

X-Rite’s MA-T instruments are equipped with an RGB camera. This full-color input, paired with image editing technology, isolates the sparkle and coarseness parameters and allows them to be calculated. This texture measurement technique uses the same illumination as used in color measurement.

We have also added diffuser plates in the instrument to measure coarseness. From these illumination sources, we have three main angle geometries to measure sparkle, as well as complimentary geometries to account for a shift in viewing angle.

Why did X-Rite Develop the MA-T12 and the MA-T6, and What does the T6 and T12 Stand for?

The T stands for texture, more specifically color, sparkle, and coarseness. The number (6 and 12) represents the amount of actual angles on the device. X-Rite has been refining its craft for more than 60 years to become global leader in color science and technology.

In today’s competitive marketplace, manufacturers increasingly use extreme effect finishes to differentiate themselves. As a result, measurement of color alone is no longer sufficient to completely characterize these materials, or to ensure consistency across adjacent parts and distributed supply chains.

An instrument was needed that could accurately capture not only color, but also the complex sparkle and coarseness characteristics in effect paints and coatings.

The MA-T devices coupled with EFX QC software make the ideal solution for accurately evaluating and verifying color, sparkle, and coarseness characteristics of effect finishes.

What is the Difference Between the MA-T6 and the MA-T12?

The MA-T6 features 6 angles of measurement and a single source of illumination. The MA-T12 features 12 angles of measurement with an additional source of illumination. This improves the performance of measuring hue-shifting pigments as they would appear from multiple viewpoints or lighting conditions.

Both can capture sparkle and coarseness. Typically, the MA-T12 will be used by paint developers and laboratory operators who want to develop formulas for automotive,plastics, and metal colors, and establish robust standards to be used throughout the entire supply chain.

The extra angles can give them more information about the pigments. The MA-T6 is designed for quality control operators that depend on consistent matches to manufacturer specifications.

EFX QC Software

EFX QC, a software solution included with the MA-T family, is a cloud-based solution that simplifies the process of defining, communicating, and ensuring conformance with standards and measurement procedures for color, sparkle, and coarseness across distributed supply chains.

This technology enables measurement and comparison in DC (Diffuse Coarseness), SG (Sparkle Grade) and CV (Color Variation) units.

EFX QC’s new visual tools, including performance trend charts and stored images of specific measurements, enable real-time performance monitoring and provide actionable insights that speed up the process of troubleshooting out-of tolerance product.

The ability to set and digitally communicate global tolerances and measurement procedures for color, sparkle, and coarseness across the supply chain improves ongoing conformance.

Real-time monitoring of color harmony across the supply chain enables quick adjustments to improve operating efficiencies, incorporates reusable digital assets, such as standards, tolerances, jobs and more, as well as job templates and standardized procedures that make measurement and data analysis easier.

The goal of X-Rite’s product development is to deliver measurement capabilities that match the way the eye sees both color and material appearance. The MA-T family are just the beginning. We’ll continue our ground-breaking research efforts into the future to advance the way people perceive, measure, manage, and communicate both color and appearance characteristics.

Anıl Gündem Güven

Industrial&InLine Sales Manager

Odak Kimya End. Ürünleri San. ve Tic. Ltd. Şti.