Bokela /Germany, has been providing services to many industries from mining to chemistry, from pharmacy to energy as a manufacturer of disc filters, drum filters and pan filters since its establishment in 1986. Filters can operate under pressure or vacuum, depending on the requirements of the process. By renewing the existing filters in the facilities without making any distinction between brands and models, Bokela can increase their performance and increase the capacity by reducing the product humidity.

Bokela is regarded by users all over the world as standard for innovation, economy and reliability.

Bokela Filtration Technologies

• Continuous Pressure Filtration and Steam Pressure Filtration – Bokela BoHiBar Filtration,

• Continuous Rotary Vacuum Filters – Bokela Disc Filters, Drum Filters, Pan Filters,

• Crossflow Filtration,

–– Dynamic membrane filtration with Bokela Bo Cross Dynamic Filter,

–– Dynamic screen filtration with Bokela BoCross MicroScreen Filter.

Bokela Offers a Wide Range of Comprehensive Services for Solid/Liquid Separation;

• Consulting,

• Product testing in the lab & test field,

• Filter Revamping – i.e. modernization and optimization of running filters.

Bokela BoHiBar Filtration

BoHiBar Filtration offers unique solutions when;

• Fine particles need to be filtered,

• Cleanest products or lowest cake moisture contents are demanded,

• High process pressures and high temperatures have to be adhered,

• Contamination have to be avoided.

Bokela BoHiBar Steam Pressure Filtration is an innovative hybrid process, developed by Bokela. BoHiBar Steam Pressure Filtration achieves lowest residual moisture and highly effective cake washing.

Applications:

White & colour pigments, calciumcarbonate (PCC), melamine, PVC, PTA/CTA/QTA, SiO2 crystallisation products.

Bokela Continuous Rotary Vacuum Filters

The continuous operation, the high performance capacity and the low space demand make rotary filters the most economical solution for a wide range of solidliquid separation tasks.

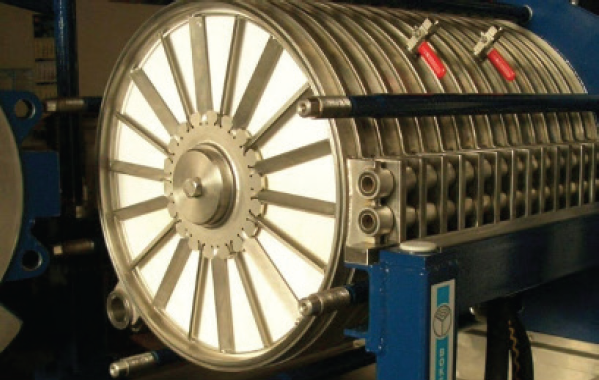

• BoVac Disc filter: Due to the modular design with different diameters and variable number of filter discs, BoVac Disc filters can be adapted to specific process conditions.

• BoVac Drum filter is characterized by excellent cake washing and a quick change of filter cloth. Cloth change could be completed in about 1–2 hours, without stopping the production. BoVac Drum filters have replaceable filter cells.

Applications:

Colour pigments, white pigments such as calcium carbonate & titanium dioxide, gypsum, potassium sulfate, caffeine, pectin, salts, zinc sulfate, zinc sulfide, catalysts, starch, crystallisation products.

• BoVac Pan filter with their horizontally arranged filter surface are particularly suited for filter cake washing. Therefore, they are preferably used for the filtration and washing of coarse-grained and rapidly sedimenting suspensions.

Bokela CrossFlow Filtration

• With BoCross Dynamic filter, micro- to nano-scale suspensions can be thickened to high concentrations. This filter is a unique process for microfiltration and ultrafiltration of microfine to nanoscale suspensions.

Applications:

White pigments like Ba-sulfate, kaolin and titanium dioxide, nano-scale products, dextrose, soya milk, pharmaceuticals.

• BoCross Microscreen filter is preferred to classifying suspensions or when solids are to be completely recovered or separated.

Applications:

Polymer suspensions, melamine, cocao butter, catalysts.

Filter Revamping- Modernization and Optimization of Running Filters

Filter revamping is an economical alternative to a new filter investment. Filter revamps enables the customer to optimize the process and operation of its already running filter system in the fastest and most economical way.

Disc, drum and pan filters from numerous OEMs have been successfully optimized by Bokela.

• 30% up to 150% solids capacity increase,

• Reduced cake moisture,

• İmproved filter operation, maintainability and safety,

• Higher filter availability,

• Significant savings in investment – only 10% to 30% of costs for new filter investment,

• Fast realization covered often under the maintenance or operational budget with no need for capital expenditure approvals.