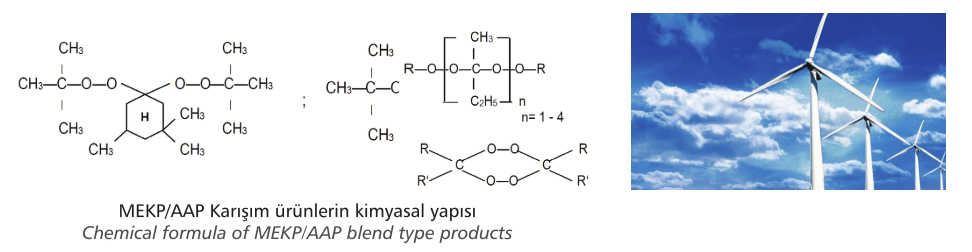

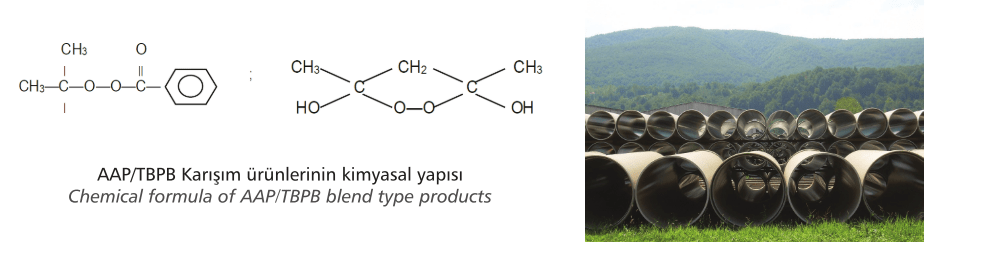

Akperox ER group products in Akpa Kimya’s product portfolio; methyl ethyl ketone peroxide / acetyl acetone peroxide blend type products and acetyl acetone peroxide/tert butyl peroxy benzoate blend type products.

When using methyl ethyl ketone peroxides and acetyl acetone peroxides alone, mixture type peroxides are produced to combine the effect they create and minimize the disadvantages that occur in both product groups.

Akperox ER11, ER33, ER34, ER37, ER73 are a blend type of Methyl Ethyl Ketone Peroxide and Acetyl Acetone Peroxide. Akperox ER59 and ER60 FW are blend type of Acetyl Acetone Peroxide and Tert Butyl Peroxy Benzoate. The only difference of ER11 from other products is that it is phthalate free. The products are used with cobalt accelerators to cure unsaturated polyester resins at both high and ambient temperatures.

Usage areas; particularly suitable for continuous production applications such as pipe production, continuous lamination, centrifugal casting, RTM (resin transfer molding), filament winding. The products are preferred for better control of the gel-cure times desired for production. The MEKP/AAP blend product + cobalt combination provides faster curing and higher peak temperature compared to the MEKP + cobalt combination.

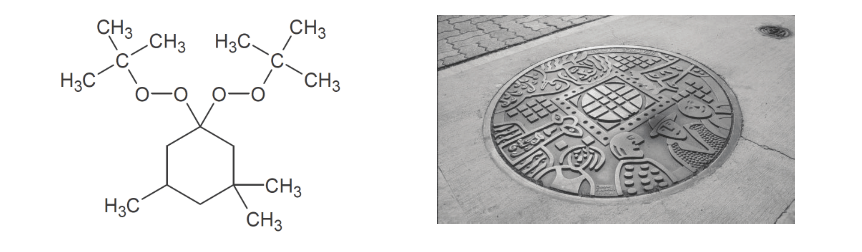

Akperox PK295 D50; 1,1-Di (tert-butylperoxyl) -3,3,5-trimethylcyclohexane, 50%

The product in the cycloaliphatic percetal group is used as an initiator (radical source) for curing of unsaturated polyester resins at elevated temperature. It is especially preferred in SMC – BMC hot press applications. It operates in the temperature range of 120-170°C depending on the application.

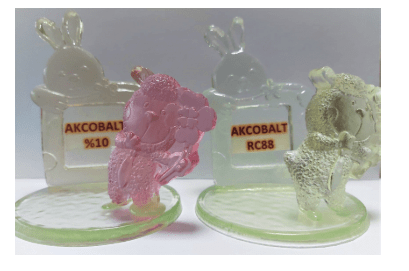

Akcobalt RC88;

Curing of unsaturated polyester resins is not only provided by organic peroxides. An accelerator should also be added. Accelerators are chemicals that activate peroxide.

Cobalt metal is an accelerator used for ketone peroxide-based curing systems. Disadvantages of cobalt using at to cure of unsaturated polyester resin are to change the product color in transparent product applications.

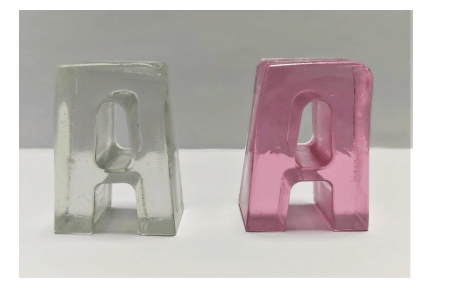

For this reason, Akpa Kimya developed and started the production of colorless cobalt product under name of Akcobalt RC88. The product is especially preferred for transparent applications. These visuals include applications prepared with resin + initiator + cobalt accelerator in Akpa Kimya’s laboratory environment. While cobalt changes the resin color in the application using standard cobalt, it is seen transparent of resin in the application made with Akcobalt RC88.

These visuals include applications prepared with resin + initiator + cobalt accelerator in Akpa Kimya’s laboratory environment. While cobalt changes the resin color in the application using standard cobalt, it is seen transparent of resin in the application made with Akcobalt RC88.

Simge Arık

R&D Specialist

Akpa Kimya