WAGNER TOPFINISH Bell & Variants

Electrostatic bell spraying is a painting process in which a high-speed rotating device with high electrical potential atomizes the paint that produces charged droplets and sprayes them onto a surface with the help of air. These devices generally use a forming-air system that directs particles to the target, together with electrostatic forces.

It provides superior transfer efficiency and high quality coating due to the automatic paint technique in the industries where high volume and multiple production is done in the industries or in areas such as automotive industry where sensitivity is very important.

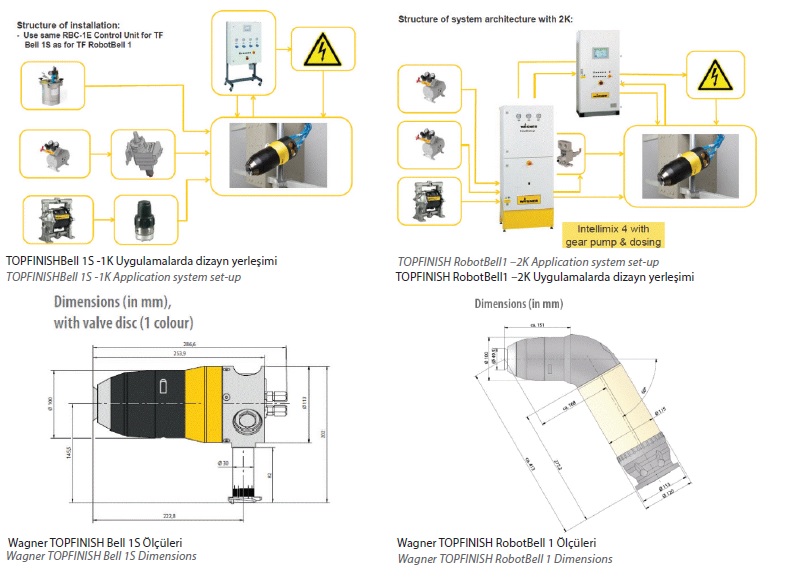

Applicator with focusing feature is applied with high speed paint electrostatic loading to the surface and area to be painted with the existing bell. The Wagner TOPFINISH Bell 1S expands the range of high-speed rotation atomisers to meet the increasing demands for automation in liquid coating.

While the RobotBell can be mounted on a robot arm, the TOPFINISH Bell 1S has been specially designed for use with reciprocators and linear axes. It is ideal for electrostatic applications with water and solvent-based paints and can be applied for automated where highquality. surfaces are required.

Ideal coating results with super-fine atomisation. High variability thanks to individual adjustment of the spray jet with two shroud airs – depending on the workpiece geometry requirements, both a wide, soft spray pattern and a small, hard spray jet can be generated.

Minimum effort for assembly & maintenance thanks to sturdy turbine technology and components made from stainless steel. With the high-speed rotation atomiser, Wagner TOPFINISH RobotBell 1, both small workpieces and large surfaces can be coated with maximum efficiency.

The Wagner TOPFINISH RobotBell 1 is ideal for electrostatic applications with water and solvent-based paints.

Thanks to its versatility and robust properties, it allows perfect surface coatings in a wide range of areas – such as for workpieces in the automotive, metal, plastic or wood industry.Ideal coating results with super-fine atomisation.

High variability thanks to individual adjustment of the spray jet with two shroud airs – depending on the workpiece geometry requirements, both a wide, soft spray pattern and a small, hard spray jet can be generated. Minimum effort for assembly & maintenance thanks to sturdy turbine technology and components made from stainless steel.

Advanced High Speed Rotation Applicator for Reciprocator and Fixed Arrangements

• Superior atomization for top finish quality,

• Superior transfer efficiency,

• Minimal air consumption,

• Fast color change < 5 sec for up to 4 colors,

• Integrated 2K version available.

Variant of TOP FINISH RobotBell uses same key components such as bell cups ,turbine and valve disc. Spare and wear parts are the same. Light weight and compact product which can be easily and flexible mounted to any fixed arrangement.

Processable material

• Solvent-based paint 1K / 2K

• Water-based paint 1K / 2K

• UV paint

• Sol-gel

• Micro corrosion protection paint

Typical Applications

• Agricultural & construction machine components,

• Furniture, window frames,

• Plastic components,

• Automotive industry (e. g. wheel rims),

• Other industrial applications.

Optimized for usage with reciprocators and fixed axes:

• Light weight: 4 kg

• Concept with a two shroud air rings to achieve huge spray pattern variations,

• More compact & service friendly due to radial inserted valves,

• Internal / external flushing of the bell cup,

• Applicable to solvent and waterborne paint,

• Useable with High Voltage up to 100 KV,

• CE, AtexZone 2 certified,

• Standard control unit available: RBC 1E

Depending on shapeand size of the parts to be coated customers can choose the most appropriate size and formof the bell cup. Smaller parts could be sprayed with 30mm bell cup diameter. If squaremeter,flat parts or even just high paint flowrates are more important,we suggest to use the 70mm bellcup.

We assume that the bellcup 50mm will be use dasanall-rounder. Permaterial and application the most appropriates erration can be chosen.

Key Benefits –Spray Pattern Adjustment

The variable spray pattern will create aapplicator for awide variety of applications! Two shroud air createa huge variation on the spray pattern from 80mm to 800mm. This will increase the flexibility and also the overall performance.

The traditional bell applicationis to provide mainly a wide and softspray pattern but also to reach deep corners and edges with a hard spray pattern. • Good penetration by smaller spray pattern. • Good coverage by wide spray pattern with good coverage.

Wagner TOPFINISH RobotBellI -Control Unit RBC 1E

Enables to sell complete CE certified package Robot Bell plus Control Unit. Standard Versions available on demand for specialized & trained dealer / systems integrators, includes:

Including:

• Closed Loop Speed Control

• High Voltage Closed Loop

• Control of air & proportional valves (1 paint/solvent/ dump)

• Control of process parameters like shaping air, high voltage

• Recipes programming & control (Speed Bell HV, SA1,SA2)

• Two Cascade cabinet options for HV generation:

1.Including discharger unit for solvent paint applications

2.With earth switch for waterborne applications

• Emergency Stop

• Security controlled main air ( deactivation in case of fire & exhaust air not ok)

• Security interface performance level D with “booth ok” and “ protective door”

• Interface for high voltage illumination & alarm horn

• Can be control by external Robot Control via Robot Interface (digital / analog: Speed Bell HV, SA1,SA2)

• Paint flow control need to be implemented by an external solution.

Mustafa Acıpayamoğlu – Yük. Endüstri Mühendisi – Industrial Engineer, MSc – Genel Müdür – General Manager – Altermak