1. Introduction

Wound dressings are medical textile products that help the wounds to heal rapidly in health-friendly environments and conditions (Ersoy et al., 2015). Medical textiles or so-called.

Medtech textile materials have been developing rapidly in the textile industry recently. Medical textiles are textile materials produced or designed for medical conditions. Surgical yarns, dressings, dressings, bandages, artificial organs and so on.

Materials such as medical textile products are among (Dogan and Basal, 2009). Medical textiles are textile materials designed to be widely used in all areas of medicine and surgery.

Medical textiles should be biocompatible with the surrounding tissue and should be combined with different materials. If we list the general characteristics desired from medical textiles depending on the field of use; strength, antitoxic, elasticity, antiallergic, durability and biocompatibility.

Biomedical materials can be contaminated with bacteria, and sterilization of biomedical materials is one of the most important and important elements (Al-sherbini et al., 2015). Antioxidants have become one of the important issues in human nutrition in recent years. This is due to the ability of free radicals to remove.

In addition, synthetic and natural antioxidants are used to treat nutrients for a long time. While these antioxidants protect the food, they also show protection against the oxidizing substances (Yavaşer, 2011). Antioxidants strengthen the body’s immune system and have properties such as aging retardant.

Black rice is a nutrient source with high antioxidant value. Black rice aroma is derived from acetyl pyrrole, while its color is derived from anthocyanin, cyanidine and 3-0-beta glucoside (Shao et al., 2018).

PU are copolymers containing urethane groups in their structures (Yeganeh and Hojati-Talemi, 2007). Physical and mechanical properties and good biocompatibility provided a wide variety of uses (Gültekin, 2006). With these properties, it is also used as wound dressing material.

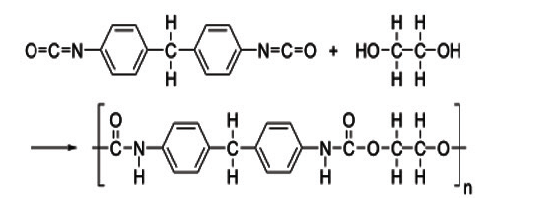

Wound dressing facilitates epidermal cell migration by preventing the risk of losing water on the wound surface (Zlatanic et al., 2004). Figure 1 shows the linear PU structure.

Figure 1. Linear PU structure (Zlatanic et al., 2004)

In this study, food packaging product and wound healing tape materials were produced from PU-Black rice biocomposites by electrospinning method. Characterization studies of nanostructured composites were carried out with the help of structural (FTIR), morphological (FEGSEM), thermal (DSC) and mechanical (tensile) analysis/testing. Prepared PU nanofiber structures with black brass additive are expected to have significant potential in the food sector mainly as packaging product and wound healing tape materials in tissue engineering.

2. Materials and Methods ,

2.1 Used Materials

Black rice was obtained from a local market in Istanbul. In biocomposite production of PU (Lubrizol Advanced material Inc. Cleveland United States) and dimethylformamide to solve polymers (DMF-HCON (OH3)2) (Sigma- Aldrich/Turkey) and ethyl acetate (C4H8O2) (Sigma- Aldrich/Turkey) as organic solvents were used. In the electrospinning phase, biocomposite was used as oil base paper.

2.2 Production of Black Rice Reinforced PU

Nanofibers by Electrospinning Method

14% PU and 1%, 5%, 8% black rice added %14 PU nanofibers were dissolved in DMF/Ethyl acetate solvent system mixed with 80/20% by volume at 40°C for 2 hours and made suitable for nanofiber production process by electrospinning method.

The nanofiber production process was made from 1%, 5%, 8% black rice solutions fortified to 14% PU and 14% PU matrix.

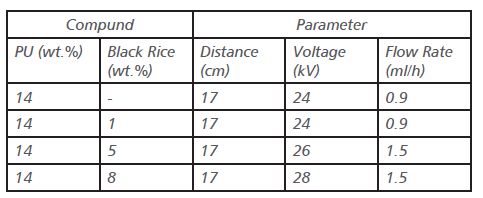

The production process is based on the parameter values in Table 1. Table 1 shows the parameter values applied to the electrospinning solutions. Figure 2 shows the production stages of the biocomposite product.

Table 1. Biocomposite production parameters by

electrospinning method (Bozkurt et al., 2017)

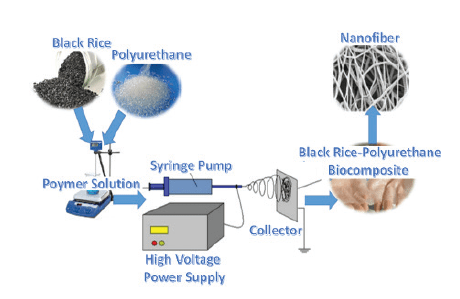

Figure 2. Production of black brass reinforced PU

nanofibers by electrospinning

2.3 Characterization Studies

Structural analysis of the biocomposites the functional groups found in the structures of the samples were determined based on the percent transmittance (T%) determined in the wavelength range of 400- 4000 cm-1 with Jasco 6600 FTIR device.

Morphological analysis Quanta FEG 450 FEGSEM device with high resolution nanofiber images were taken, the average diameter thickness of these nanofibers was measured with Image j (2011) software. Thermal analysis with Hitachi 7000X instrument at 10°C/min.

DSC analyzes were applied to 10 mg weighed biocomposite samples in 3 steps at -50-140°C temperature range.

Mechanical analysis According to ASTM standards, the thicknesses of the samples which were cut 1×5 cm in size were measured with OKR brand micrometer and the Zwickline test device was adjusted to 5 mm/minute tensile speed under 500 N load, and the mechanical properties were determined with the device. In the test process, three replications were made from four different samples and their mean values were taken as basis.

3. Discussion

3.1 FTIR Analysis

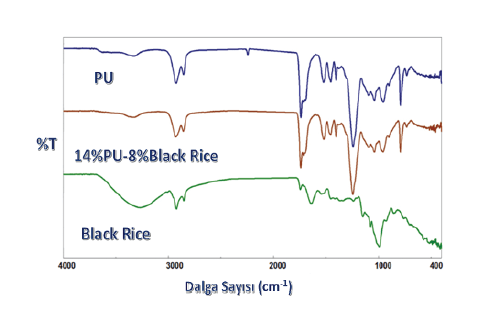

When the PU structure spectrum was evaluated, it was determined that N-H tensile band was 3325 cm-1, CH2 tensile band was 2956 cm-1 and C=O absorption bands were 1701 and 1727 cm-1 wavelengths. The C-C tensile bands in the benzene ring have a frequency of 1464 cm-1 and 1597 cm-1, bands of N-H and C-N bonds in the amide group have a wavelength of 1527 cm-1, and C-O-C tensile bands of 916 cm-1 and 1100 cm-1 wave numbers (Chiono and et al., 2014). The black rice particles reduced the wavelength intensity of the functional groups of the PU structure while at the same time shifting the tensile band values slightly. In the 14% PU-8% black rice biocomposite structure, it was observed that the functional groups of PU and black rice particles overlap. Figure 3 shows the FTIR spectrum of PU-Black rice biocomposite.

Figure 3. FTIR spectrum of

PU-Black rice biocomposite

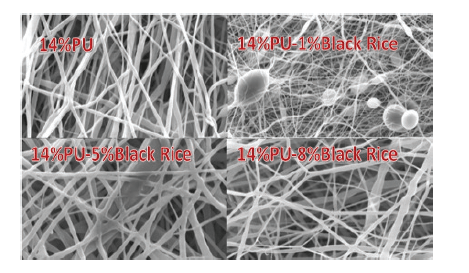

3.2 FEGSEM Analysis

It has been found that black rice particles fortified to the polymeric matrix reduce the formation of agglomeration by increasing the concentration. It has been observed that as the concentration ratio of the reinforced black rice particles is increased, the black rice particles are homogeneously coated on the fibers.

In addition, in the electrospinning stage, it was determined that the nanofibers dispersion changes depending on the flow, voltage, distance between the collector plate-feeder tip and the rotation speed of the collector plate.

The fiber structures of the samples with increased concentration were determined by the presence of FEGSEM images in which the fibers took a homogeneous shape and the fibers did not show agglomeration by thinning (Tijing et al., 2012; Bozkurt et al., 2017).

The diameters of nanofibers were measured with the help of Image j (2011) software, which is one of the FEGSEM images in Figure 4. The nanofiber diameters were reduced with increasing concentration of black rice particles.

The nanofiber diameters were 30-350 nm with Image j (2011) software. The diameters of approximately 50 nanofiber structures were measured and the average diameter values were taken as basis. Figure 4 shows the FEGSEM images of PUBlack rice biocomposites.

Figure 4. FEGSEM images of PU-Black rice

biocomposites

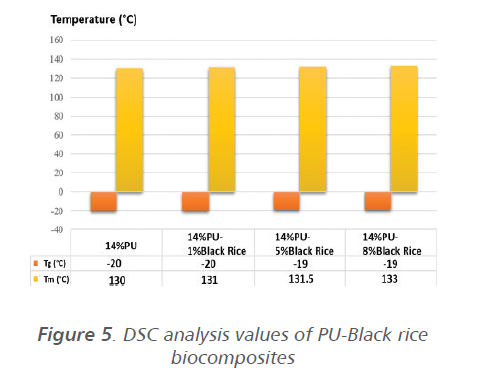

3.3 DSC Analysis

When the thermal analysis results of PU-Black rice biocomposite were examined, it was observed that the increase in glassy transition (Tg) and melting points (Tm) increased with increasing black rice concentration in black rice reinforced biocomposites compared to pure PU polymer.

Biocomposites with high thermal properties were obtained for use in food packaging and wound healing products (Anandhan and Lee, 2014). Figure 5 shows the DSC analysis results of PU-Black rice biocomposites.

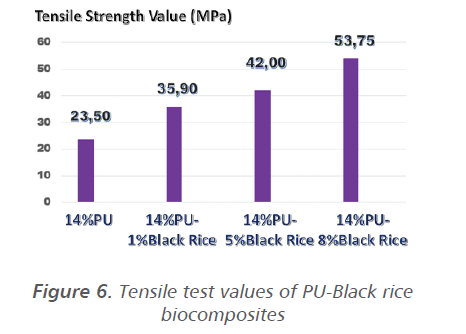

3.4 Tensile Analysis

It has been observed that the strength value increases linearly due to the increase in the concentration percentages of the black rice particles fortified to the PU matrix material. As it can be seen from the FEGSEM images obtained as a result of morphological investigations, our mechanical properties increased for these biocomposites in accordance with the results that black rice particles were homogeneously coated on polymer fibers and no clumping formation was observed.

Biocomposites have been produced which have strength over the mechanical results found in the conjugate studies in the literature. 14% PU-8% Black brass sample obtained the strength value was found to be the highest value obtained in our study.

It was concluded that this increase in strength was a result of both the high load bearing polymeric matrix, the reinforcement of black rice particles and the homogeneous distribution in the biocomposite (Bozkurt et al., 2017). Figure 6 shows the tensile test values graph of PU-Black rice biocomposites.

4. Conclusion

When the results of the study were evaluated, biocompatible and biodegradable food packaging product and wound dressing tape were produced successfully from black rice reinforced PU matrix materials.

Functional groups determined by FTIR analysis and black rice and PU materials contained in PU-Black rice biocomposite structure were determined.

As a result of FEGSEM analysis, fiber sizes of PU and PU-Black rice nanofibers were determined to be 30-350 nm by measuring Image J (2011) software. It has been observed that the nanofiber diameters of these fine fibers are not broken, and black rice particles encircle the PU fibers homogeneously.

When mechanical tests were applied to the produced biocomposites, the highest test value was reached in 14% PU-8% Black rice biocomposite compared to other samples. In case of tests such as antioxidant and cell culture, biocomposite samples will be able to guide future studies.

Acknowledgment

We thank Arel University ArelPOTKAM (Polymer Technologies and Composite Application and Research Center) team and Zwick-Roell company managers and employees who assisted in the mechanical analysis studies of biocomposites.

- References

ERSOY, Y., DURAN, M., & TAYYAR, A. E. (2015). Tıbbi Tekstiller ve

Yara Örtüsü. Düzce Üniversitesi Bilim ve Teknoloji Dergisi, 3(2).

DOĞAN, G., & BAŞAL, G. (2009). Elektrolif çekim yöntemine göre

elde edilen biyopolimer nanoliflerin ilaç salınım sistemleri yara örtüsü

ve doku iskelesi olarak kullanımları. Tekstil Teknolojileri Elektronik

Dergisi, 3(2), 58-70.

AL-SHERBINI, A., RAGAB, S. S., & EL-SAYED, H. H. (2015). Antimicrobial

Effects of Silver Nanoparticles Mediated Cosmetic Cream and

Cotton Gauze on Candida Strains. Journal of Pharmachy and Biological

Science, 10(3), 69-75.

YAVAŞER, R. (2011). Doğal ve sentetik antioksidan bileşiklerin antioksidan

kapasitelerinin karşılaştırılması, Yüksek Lisans Tezi, Adnan

Menderes Üniversitesi, Fen Bilimleri Enstitüsü, Aydın.

SHAO, Y., Hu, Z., YU, Y., MOU, R., ZHU, Z., & BETA, T. (2018). Phenolic

acids, anthocyanins, proanthocyanidins, antioxidant activity, minerals

and their correlations in non-pigmented, red, and black rice.

Food chemistry, 239, 733-741.

YEGANEH, H., & HOJATI-TALEMI, P. (2007). Preparation and properties

of novel biodegradable polyurethane networks based on castor

oil and poly (ethylene glycol). Polymer Degradation and Stability,

92(3), 480-489.

GÜLTEKİN, G. (2006). Yara örtü malzemesi uygulamaları için yağ asiti

temelli poliüretan filmlerin üretimi, Yüksek Lisans Tezi, İTÜ Fen Bilimleri

Enstitüsü, İstanbul.

ZLATANIĆ, A., LAVA, C., ZHANG, W., & PETROVIĆ, Z. S. (2004). Effect

of structure on properties of polyols and polyurethanes based on

different vegetable oils. Journal of Polymer Science Part B: Polymer

Physics, 42(5), 809-819.

BOZKURT, Y., SAHIN, A., SUNULU, A., AYDOGDU, M. O., ALTUN, E.,

OKTAR, F. N., … & GUNDUZ, O. (2017). Electrospun Nanocomposite

Materials, A Novel Synergy of Polyurethane and Bovine Derived

Hydroxyapatite. In Journal of Physics: Conference Series (Vol. 829,

No. 1, p. 012015). IOP Publishing.

CHIONO, V., MOZETIC, P., BOFFITO, M., SARTORI, S., GIOFFREDI,

E., SILVESTRI, A., … & DI MEGLIO, F. (2014). Polyurethane-based

scaffolds for myocardial tissue engineering. Interface focus, 4(1),

20130045.

TIJING, L. D., RUELO, M. T. G., AMARJARGAL, A., PANT, H. R., PARK,

C. H., KIM, D. W., & KIM, C. S. (2012). Antibacterial and superhydrophilic

electrospun polyurethane nanocomposite fibers containing

tourmaline nanoparticles. Chemical Engineering Journal, 197,

41-48.

ANANDHAN, S., & LEE, H. S. (2014). Influence of organically modified

clay mineral on domain structure and properties of segmented

thermoplastic polyurethane elastomer. Journal of Elastomers & Plastics,

46(3), 217-232.

Asist. Prof. Dr. Yeşim Müge Şahin Erdi Buluş

Asist. Prof. Dr. Yeşim Müge Şahin Erdi Buluş

Center Manager

Istanbul Arel University – ArelPOTKAM

Erdi Buluş

Metallurgical and Materials High Engineer

Material Technologies Specialist

Istanbul Arel University ArelPOTKAM