Abstract

Lignin, when exposed to the sunlight, can easily be degraded. To preserve the beauty of wood grain, waterborne clear coats containing UV absorbers and light stabilizers are commonly applied to the surface for protection.

However, the effectiveness of such application is limited. According to our studies, pretreatment of wood surface prior to the application of clear top coat can effectively extend the protection of lignin from UV light degradation.

Eversorb® AQ, a blend of UV absorber and HALS, is developed by Everlight Chemical Industrial Corporation (ECIC) specifically for waterborne clear coats. Eversorb® SB, designed for wood pretreatments, can protect lignin from UV light degradation.

For Eversorb® AQ, the effect factor of wood protection ability was about 14.69%.

For Eversorb® SB, the effect factor of wood protection ability was about 13.35%. Eversorb® AQ and Eversorb® SB have interaction effect. The effect factor is 10.9%. Both of Eversorb ® AQ and Eversorb® SB are good performance for wood protection.

This paper is a comparison study using accelerated weathering method to test different wood types pretreated with or without Eversorb® SB in different cosolvents. Design of Experiment (DOE) was used in this study.

Our data confirmed that pretreatment with Eversorb® SB have better performance in UV light degradation test.

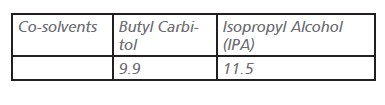

Lignin is a complex organic polymer contains hydroxyl functional groups (-OH). Two types of co-solvents, isopropyl alcohol and butyl carbitol, are tested in the system, the solubility parameters are 11.5 and 9.9, respectively. After weathering test, Eversorb® SB mixed with isopropyl alcohol gives a better result to butyl carbitol.

Due to higher lignin content in softwoods (25–35%) to hardwoods (18–25%), theoretically, Eversorb® SB pre-treatment could offer better protection to softwoods.

Our data supports the hypothesis; pre-treatment with Eversorb® SB provides much significant protection in softwoods (Southern Pine and Douglas Fir) than in hardwoods (Cedar, Southern Beech and African Teak).

Introduction

Waterborne clear coatings have been developed to address the concerns of high VOC that are normally associated with conventional solvent-based coatings [1]. Most customers use waterborne clear wood coatings to protect wood materials.

However, sunlight and UV radiation can penetrate coatings on wood surface, causing yellowing. The yellowness comes from both coating and lignin. Wood, as a composition of lignin, cellulose and hemicelluloses, appear yellowing due to the photodegradation of lignin [2- 6].

Photodegradation route of lignin [7-8] is shown in Figure 1.

Figure 1. Route of photodegradation of lignin

Eversorb® AQ is a waterborne light stabilizer. Eversorb ® SB is a lignin stabilizer designed for wood pretreatments. Test data confirmed that by increasing the concentration of Eversorb® AQ in the clear top coat can effectively protect Southern Pine from UV light degradation.

Further experiment shows that the pretreatment on Southern Pine with Eversorb® SB prior to the application of clear top coat provides better weatherability than the one without Eversorb® SB pretreatment.

Furthermore, data also suggested that by increasing the coating thickness, the light fastness of Southern Pine can also be improved to some degrees, but not as effective as other methods such as increasing the dosage of light stabilizers in the clear coat or pretreating the Southern Pine prior to the clear coat application [9].

Lignin is a complex organic polymer contains hydroxyl functional groups (-OH). To check if solvents can affect the protection performance of Eversorb® SB, different co-solvents are used to mixed with Eversorb® SB in the experiment.

Theoretically, Eversorb® SB pretreatment can have better performance on softwoods than on hardwoods due to higher lignin content. Softwoods contain 25–35% lignin and hardwoods contain 18–25% lignin [10].

The subjects of this paper are 5 different types of woods, including softwoods (Southern Pine and Douglas Fir) and hardwoods (Cedar, Southern Beech and African Teak).

Experiment

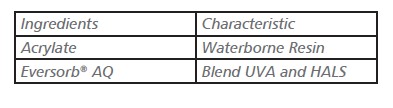

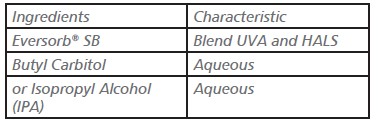

The three model formulations used in this study were an acrylic-based waterborne clear coating, wood pretreatments and co-solvents.

Their detail compositions are shown in Table 1, Table 2 and Table 3. 5 different woods were chosen in the region as shown in Figure 2. Design of Experiment (DOE) was used to design test runs as well as to analyze test data. DOE technique allows us to validate the data.

Table 1. Compositions of waterborne model formulation

Table 2. Compositions of wood pretreatments model formulation

Table 3. Solubility parameter of different co-solvents (Unit: (cal/cm3)1/2)

Screening Design of Different Type of Woods and Co-solvents by using EV-AQ and EV-SB

Screening design (Table 4) was used to identify factors that get the minimal color change after weathering test. Mathematical model derived from data indicates all factors –X1:5 different type of woods (Cedar, Douglas Fir, Southern Beech, African Teak and Southern Pine).

X2:3 type of treatments (X2-1: Top Coat: Waterborne Acrylic Resin, X2-2: Wood Pretreatment: Butyl Carbitol mixed with EV-SB, Top Coat: EV-AQ mixed with Acrylic Resin and X2-3: Wood Pretreatment: IPA mixed with EV-SB, Top Coat: EV-AQ mixed with Acrylic Resin).

Figure 2. Different type of woods

Table 4. Details of screening design and test results

The Optimal Prediction Profiler

The prediction profiler (for example, Southern Pine) shows that effect of 3 type of treatments after weathering test for 300 hrs.

For the item which uses waterborne acrylic resin only, the yellowing after weathering test is significant. (color difference ΔE=31.85) (as shown in Figure 3). The 10% EV-SB mixed with Butyl Carbitol in the pretreatment and 2% EV-AQ in top coat.

The performance is better than the Blank (color difference ΔE=10.25) (as shown in Figure 4). The 10% EV-SB mixed with IPA in the pretreatment and 2% EV- AQ in top coat.

The light fastness of Southern Pine is the best. (color difference ΔE=6.55) (as shown in Figure 5). The photos of different type woods after weathering test are shown in Figure 6 to Figure 10.

Figure 3. The effect of Southern Pine coated with acrylic resin

after weathering for 300 hrs (Predicton Profiler).

Figure 4. The effect of Southern Pine and pretreatments with

butyl carbitol after weathering for 300 hrs (Prediction Profiler)

Figure 5. The effect of Southern pine and pretreatments with

IPA after weathering for 300 hrs (Prediction Profiler)

Figure 6. Photo of Douglas fir after weathering test for 300hrs

Figure 7. Photo of African Teak after weathering test for 300hrs

Figure 8. Photo of Southern Beech after weathering test for 300hrs

Şekil 9. 300 saat için ayrışma testinden sonra Southern Pine’un fotoğrafı

Figure 10. Photo of Luanta-fir after weathering test for 300hrs

Results

After weathering test, the result shows that the mixture of Eversorb® SB and Eversorb® AQ can significantly protect wood surfaces from yellowing. In addition, Eversorb® SB mixed with isopropyl alcohol can provide better performance than Eversorb® SB mixed with butyl carbitol.

Conclusion

Environmentally friendly coatings are the trend for future development. We have developed several unique products specifically for coatings.

Eversorb® AQ, a blend of UV absorber and HALS, is developed for waterborne clear coats. Eversorb® SB, designed for wood pretreatments, can protect lignin from UV light degradation.

Lignin is a complex organic polymer contains hydroxyl functional groups (-OH). The solubility parameter of isopropyl alcohol and butyl carbitol are 11.5 and 9.9, respectively. After weathering test, the result shows Eversorb® SB can provide better performance in isopropyl alcohol than in butyl carbitol. In other words, the higher solubility parameter of the solvents can offer the better protection.

Due to higher lignin content in softwoods (25–35%) to hardwoods (18–25%), theoretically, Eversorb® SB pre-treatment could offer better protection to softwoods. Our data indicates that pre-treatment with Eversorb® SB provides much significant protection in softwoods (Southern Pine and Douglas Fir) comparing with hardwoods (Cedar, Southern Beech and African Teak).

Coating manufacturers may still need to run the experiments to confirm its coating systems compatibility. Also, a tailor-made UV absorber and light stabilizer package can be offering to fulfill your special needs.

Yung-Chi Yang

Manager Technical Service of Specialty Chemical

Everlight Chemical Industrial Corp

Samir Günaştı

General Manager

ELİTE A.Ş.