Abstract

Evaluation of explosion risk in industrial facilities, identification of dangerous zones in which explosive atmospheres may be detected and determination of zone conditions shall be made according to TS EN 60079-10-1 and TS EN 60079-10-2 standards.

Installations in which flammable materials are loaded or stored, must be designed, constructed, operated and maintained during normal or unusual operation to minimize the emission of all flammable substances and the size of the resulting hazardous areas, the frequency, duration and quantity of the emissions.

The size of the explosive medium is determined by the amount of release, the amount of time the released substance remains in the environment. Reduction of the amount of emissions and use of Atex equipment in the region are the most important factors when taking explosive measures.

Another precaution is to reduce the amount of time the released substance is released from the environment and to provide an environment below the Lower explosive limits that create explosive properties.

In the processes, the effect of air on the gas and steam is released into the working environment. The gas and vapor concentration may be reduced in part, in such a case it is important for the diffusion mechanism in the concentration change.

Proper ventilation reduces the persistence of the hazardous area in the explosive gas environment. The gas and vapor released into the atmosphere are diluted in the air by diffusion and lowered below the lower explosive limit value.

Ventilation and air movement have two basic functions.

These; the reduction of the danger zone by reducing the persistence of the explosive gas environment by increasing the dilution to reduce the hazardous zone coverage limit.

There are therefore two basic types of ventilation. Natural ventilation and Mechanical (forced) Ventilation.

Explosive Gas Environment

The explosive gas and dust medium is the mixture of air with gas and vapor or flammable materials under normal atmospheric conditions. After ignition, the explosion is spread over the entire unburned mixture (IEC 60079-10-1).

1. Flammable gas and vapor or dust density is low, the air density is too high, so-called very weak mixtures, and in such a case, burning does not occur, so an ideal security environment occurs,

2. When the flammable gas and vapor or dust density increase and reach a certain concentration, when the “Lower Explosion”limit and in “Upper Explosion” limit “values of the substance are reached, explosion and combustion occur at any value between these two values. In order to prevent this situation, the air density must be increased and lowered below the lower explosive limit value of the chemical substance,

3. Air density is low, flammable gas and vapor density is high in the case of very rich mixtures.

Evaluation of Explosive Environment

Flammable and combustible chemicals used in chemical processes and workplaces,

• To prevent damage to the employee, the working environment and the environment,

* prevention of explosive atmosphere or,

* due to the nature of the process, where the formation of an explosive atmosphere is unavoidable, measures should be taken to prevent the explosive atmosphere

from igniting and, consequently, to reduce the harmful effects of the explosion.

Figure 1. Gas concentration in the atmosphere

distribution

Hazardous area for the presence of explosive gas atmosphere Zone 0, Zone 1, Zone 20, Zone 21.

Non-hazardous area for the presence of explosive gas atmosphere Zone 2, Zone 22.

General Safety Principles

Design, construction, operation and maintenance of flammable and explosive substances during normal or unusual operation, such as loading, unloading, storage facilities, all flammable substance emissions and the size of the resulting hazardous areas, in terms of the frequency, duration and amount of release, it should be done.

Reducing the Effects of Hazardous Environment

Control measures to be implemented in order of priority in eliminating risk;

• The amount of hazardous substances should be minimized,

• Prevent or minimize the spread of dangerous substances,

• Dangerous substances to prevent the formation of a dangerous atmosphere to remove the environment through ventilation or to dilute the dangerous atmosphere in the environment,

•Avoid ignition sources,

•To control the risks of temperature, pressure and liquid overflow that may cause danger. low speed to the environment. The ventilation system designed in closed areas should also not affect the comfort of the employees.

The basic principle of document preparation is as follows: It is to determine whether the results of ignition of the explosive atmosphere after completion of the zone classification require the use of hardware with a higher level of hardware protection, or if the equipment with lower hardware protection level than is normally required is used.

The Importance of Ventilation in Explosive Media

Gas and vapor dissipation are common in low-speed industrial processes.

Conditions such as open surfaces, drainage, printing machines and evaporation of flammable liquids such as paint manufacturing are cases in which the propagation occurs at low speed. Due to minor leakages and leaks in pressurized equipment, gas and vapor discharge occurs.

Release

•A gas which may be in elevated temperature or pressure,

•A liquefied gas (eg LPG) by applying pressure,

•A liquefied gas (eg methane) with cooling only,

•A liquid and flammable vapor release associated with this fluid.

Due to the release of gas, steam, mist and dust in the belt to create explosive atmosphere. The size of the explosive medium is determined by the amount of release, the amount of time the released substance remains in the environment.

When taking explosive measures; Reduction of the amount of emission and use of Atex equipment in the region is the most important. Another precaution is to reduce the amount of time the released substance remains in the environment and to provide an environment below the lower explosion limits that create explosive properties.

Ventilation and Refreshing

In the processes, air movements are effective in the release of gas and vapor or dust into the working environment. Ventilation, gas and dust concentrations can be reduced in some cases, in which case the ventilation character is important in changing the concentration.

Proper ventilation reduces the persistence of the hazardous area in the environment of explosive gas and dust. The gas and vapor released into the atmosphere are diluted in the air by diffusion and lowered below the lower explosive limit value.

Comparison of Air Conditioning and Sailing

Ventilation mechanically enables the inlet and outlet of the air in the closed area. Dilution is the mechanical distribution of the gas and vapor cloud. Hazardous gas, steam and liquid work in closed spaces is inversely proportional to the danger ventilation.

The intensity and spreading speed of the gas emitted by the emission source will depend on the sensitivity of the ventilation.

Evaluation of Ventilation Speed

The removal of the explosive atmosphere from the area is provided by air flow, natural ventilation and mechanical ventilation systems. The best condition is to deliver the air homogeneously and at low speed to the environment. The ventilation system designed in closed areas should also not affect the comfort of the employees.

Wind speed of natural ventilation is 0.5 m s. The average annual wind speed of the world terrestrial areas is 5.1 m/s.

Air velocity less than 0.1 m/s is not detected and creates a feeling of airlessness;

Speed between 0.25 m/s and 0.50 m / s is insufficient.

Air velocity of 1.5 m/s and above creates air flow and is effective.

Ventilation Types

Ventilation is achieved by moving the air differently by wind or by temperature or by artificial means such as a ventilator. There are two main types of ventilation.

•Natural Ventilation,

•Mechanical (Forced) Ventilation (General and Local Ventilation).

Mechanical Ventilation

a) With mechanical ventilation; explosive atmosphere zone type and region coverage can be reduced,

b) It is possible to reduce the retention time of the explosive gas atmosphere,

c) Formation of explosive gas environment can be prevented.

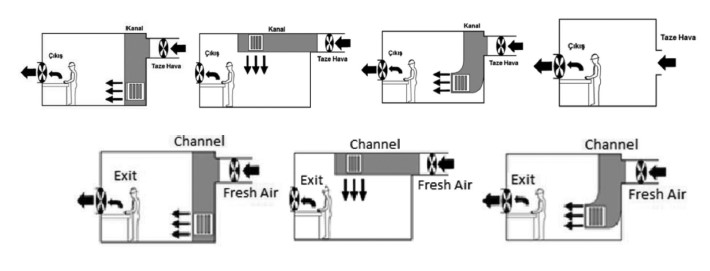

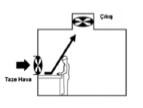

Recommended Ventilation Examples

Non-Recommended Ventilation Example

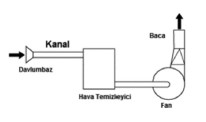

Basic Components of Local Exhaust System

In a Good Ventilation System

1.Provide necessary fresh air to the environment,

2.There should not be any air flow (discharges) that would cause discomfort in the environment,

3.Ventilation system should distribute the ambient air uniformly,

4.Ventilators should work silently if available.

Most capture speeds are about 0.5 m/s.

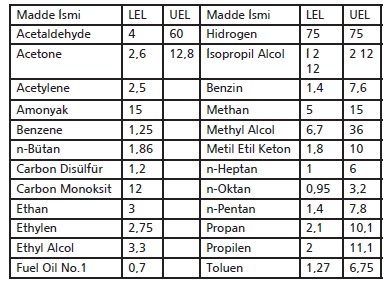

Upper and Lower Limits of Certain Chemical Explosion

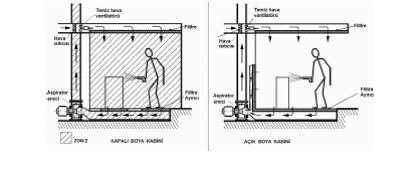

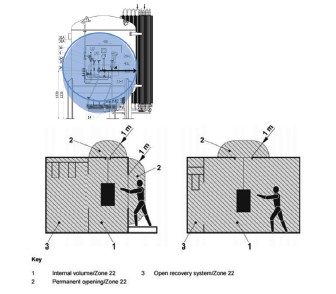

Powder Coating Booths Zone’s

İlker Erdoğan

Chemical Engineer

İSGDER- Technical Safety