New Generation Polycarboxylate Ether as Plasticizer in Concrete and Construction Application

Polycarboxylate ether, often known as PCE or superplasticizer, has gained popularity as an additive in the construction sector due to its potential to improve concrete strength and workability.

PCEs have been employed in a wide range of applications, including walkways, and high-rise structures and bridges.

One of the most important advantages of PCEs is their capacity to improve concrete workability. PCEs facilitate the mixing, placement and finishing of concrete, supporting more efficient construction processes with this feature.

It is also of extensive use when concrete must be pumped or placed in hard-to-reach areas as it can help prevent segregation.

PCEs increase the mechanical strength of concrete as well as improve its workability. PCEs reduce the water content required for a given settling by lowering the water-cement ratio, thus helping to increase the compressive strength of concrete.

This is particularly useful where high strength concrete is required, such as the construction of tall buildings or bridges.

Compared to other types of superplasticizers, such as sulfonated melamine formaldehyde (SMF) and sulfonated naphthalene formaldehyde (SNF), PCE offers several advantages.

It can provide a greater reduction in water content and improved workability, while also being less sensitive to changes in temperature and humidity. An important consideration when using PCEs in concrete structures is the control of air entrainment potential.

As a result of the tendency of PCEs to increase the air content of the material, the strength and durability of concrete may suffer. (1)

This can be extremely problematic when concrete is exposed to freeze-thaw cycles or other environmental variables that can lead to cracking and disintegration.

The consistency protection and water shear properties of PCE products are the parameters that are expected to be improved in terms of improving the concrete quality and workability.

Reaksiyon Kimya PCE product groups RCW 300 NP and 320 find use in the market with its

water-reducing feature, while RCW 355 is preferred as a consistency protection product.

In Table 1, analysis values of Maxflow RCW 355, whose consistency protection properties are specified, are listed.

Maxflow RCW 355, developed as a consistency preservative in Table 1, was used at 1% and 1.4% in two different trials, and dispersion tests were observed.

When the results were examined, it was determined that the spread of the product was 610 and 640 mm, respectively, at the 30th minute, similar results were obtained at both rates, and it was determined that the spread decreased from the 60th minute.

If the PCE ratio was 1%, the spread was observed even at the 120th minute, but in the tests where the amount was determined as 1,4, results close to the initial spread were obtained.

It is understood that the ideal product ratio in the determined formulation is 1,4%, but it is recommended to optimize the amounts according to the sand, aggregate content and properties of other additives.

The results obtained in the trials for the Maxflow RCW 300 NP product, which has a water-reducing feature, are listed in Table 2.

Water reducer Maxflow 300NP was used at 0.6, 1 and 1.25%, spreading and pressure values were observed. In the tests performed on the 28th day of Maxflow 300NP, it was determined that the compressive strength was quite high, and it had a positive effect on the compressive strength as the ratio increased.

Initial spread values also increased proportionally with the amount, it was observed that the ideal spread and compressive strength optimization could be optimized according to

the applications, but the product was quite successful in compressive strength.

Third Generation Hyper Plasticizer-Powder Polycarboxylate Ether

Polycarboxylate ether (PCE) is a chemical additive in powder form used in the construction industry to improve the workability and performance of concrete. Increases the fluidity of concrete, facilitates pouring and spreading.

The operation of PCE is based on the principle of increasing the strength and durability of concrete by dispersing the cement particles and reducing the water-cement ratio.

The use of PCE also allows for the reduction of cement content in concrete mixes, which helps reduce the carbon footprint of construction projects.

Therefore, PCE is considered as a sustainability-supporting material, as it reduces cement demand in concrete mixes as well as improving performance.

Considering that cement production negatively affects greenhouse gas emissions, it

is clear that PCE will significantly support reducing the carbon footprint of construction projects.

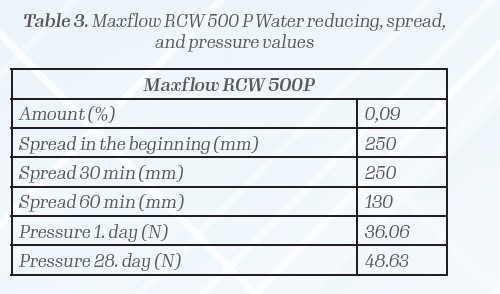

The mechanical strength and spreading tests in Gypsum applications of 3rd Generation hyper plasticizer Powder Polycarboxylate Maxflow RCW 500P are listed in Table 3 which is developed by Reaksiyon Kimya A.Ş. with the support of Tübitak Project in 2015.

As seen in Table 3, although the powder PCE Maxflow 500 P was used in very low amounts, it provided the expected dispersion values and at the end of the 28th day, a very high compressive strength was obtained.

Market Information for PCE

According to the sector reports of the Turkish Ready Mixed Concrete Association for the year 2020, the concrete admixture market in Turkey is around 457 thousand tons. (2)

The share of the domestic plasticizer, which consists of fluidizers such as naphthalene formaldehyde sulfonate and melamine formaldehyde, constitutes 80% of the total production.

While the PCE Market Size is 7,316 million dollars worldwide, it is expected to reach 9,735.3 million dollars at the end of 2027 with an annual increase of 4.2% in the 2021-27 period.

It is estimated that powdered PCE Market Size is 7,316 million dollars worldwide, it is expected to reach 9,735.3 million dollars at the end of 2027 polycarboxylates constitute a portion of approximately 365 million dollars in the 7.316-million-dollar world PC market. (3)

The European Concrete Additives Federation (EFCA) stated in its report that it presented

2020 data, that Turkey has surpassed all its competitors in Europe in the field of concrete additives with a market share of 40%.

Considering the concrete additive production potential in Turkey, it is predicted that the investments to be made in this field will appeal to a wide international market, and Turkey will gain an important place in the global market with the production of imported substitute

products in our country.

The earthquake disaster occurred in our country has once again demonstrated the importance of quality and long-lasting materials and technologies for the entire construction industry.

Reaksiyon Kimya A.Ş. targets an annual production of 12.000 tonnes with liquid form PCE,

and 3.000 tonnes of powder PCE investments expected to be completed in June 2023, and aims to meet foreign demands as well as in the Turkish market with adopting the

motto of high-quality domestic production in this direction.

Dr. Yasemin İlhan

Sales & Marketing Manager

Reaksiyon Kimya A.Ş.

References

1. Özyıldırım, Ç., Hava Sürükleyici katkıların beton dayanıklılığındaki yeri, 2. Yapılarda katkı Sempozyumu, 2007, 37-52

2. https://www.thbb.org/media/499910/thbb-hazir-beton-sekt%C3%B6r-raporu.pdf

3. https://menafn.com/qn_news_story_s.aspx?storyid=1101182162&title=Global-Polycarboxylate-Ether-PCE-Superplasticizer-

Market-Size-Worth-Around-USD-93429-million-by-2026-from-USD-7316-million-in-2020-at-a-CAGR-of-42-During-2020-2026-

with-Top-Countries-Data