Flottweg was established in 1932 in Germany and it is one of the world’s leading manufacturers of centrifugal equipments in the solid-liquid seperation industry. We, as Troya Process, are the representative of Flottweg in Turkey. Our Flottweg product range includes decanter centrifuge, belt press and separator equipment which are all widely used in the chemical, mining, food, pharmaceutical industries and mineral processing and waste treatment plants.

While two phases of a solid-liquid sludge can be separated by Flottweg decanters, it is also possible to separate 3 different phases of a solid-liquid-liquid or a solid- solid-liquid sludge by means of Flottweg tricanters with a single equipment.

The operating principles of Flottweg centrifuges comply with all applicable environmental regulations in Turkey. Due to it is gas tightness feature, it is completely appropriate for use in explosive and/or hazardous environments.

High quality duplex stainless steel is used on all surfaces of our equipment which are in contact with the product. If required by the process, special super duplex steel or Hastelloy with high corrosion resistance can also be used. Wear elements are interchangeable on-site for ease of maintenance in processes with high abrasive materials.

One of the most preffered applications of Flottweg decanters worldwide is the dewatering of paint sludge.

What is ‘Paint Sludge’?

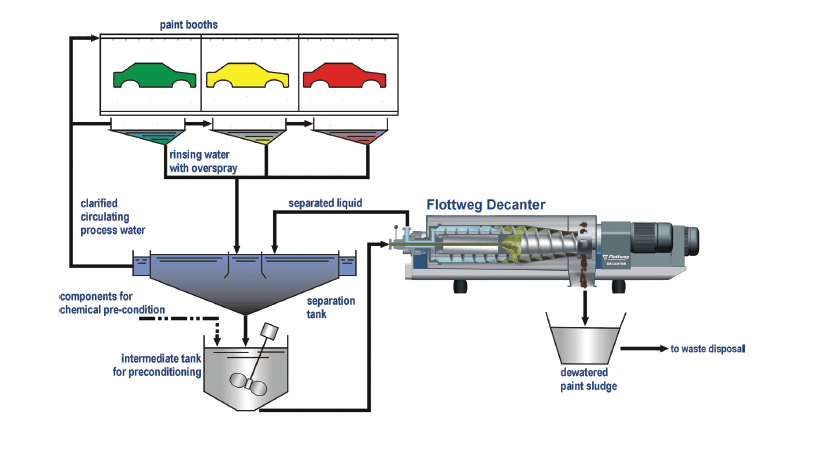

Complete and partial painting of vehicles in the automotive industry is performed by spraying in paint booths. During this process, some of the paint particles are spread into the air in the booth in the form of mist. To remove this overspray mist from the booth, the air is usually replaced with water. The so-called paint sludge is thus formed which is a mixture of water and overspray-mist.

Why Should ‘Paint Sludge’ be Dewatered?

It is highly costly to dispose the paint sludge which is classified as hazardous waste according to Regulation on Waste Management (No:29314) published by Ministry of Environment and Urbanization in the Official Gazette (02.04.2015).

As being one of the most effective methods, centrifugal dewatering process significantly reduces the cost by reducing the volume of the sludge to be disposed of.

Why Should Flottweg Decanters be Preferred for Dewatering?

• Efficient dewatering performance: Reduced sludge volume by up to 90%.

• Reduced disposal costs.

• Minimized cost for coagulant or flocculant.

• Reutilization of process water and reduced fresh water consumption.

• Maintenance-friendly design.

• Special wear protection adapted to paint sludge processing.

• Low space requirements due to compact design of the centrifuges.

As Troya Proses and Flottweg, we provide full range of service to our customers in all steps from the commissioning of our special systems to the maintanance and repair activities during the operation period. With our high quality products and experienced service staff, we are always ready to help you for a trouble-free operation.

Seçil Bıyık

Chemical Engineer

Troya Proses Makina Kimya Maden Teknolojileri Tic. Ltd. Şti.