Bühler Group emerged from the iron foundry in Gupfen in Uzwil with two employees that was established on February 10, 1860 by Adolf Bühler. In 1871, a mechanical workshop was added, and one year later the first cast rolls for roller mills were produced.

Bühler not only cast rolls, but over time also started building its own roller mills and entire grain mills. Today, Bühler is a technology company for plant and equipment and related service for processes for transforming grain into flour and animal feeds, producing pasta and chocolate, manufacturing die cast components and wet grinding&dispersion. But Bühler competence in roller mills remained the same.

Bühler three-roll mills are considered preferred technology in the production of printing inks and pasty products for a wide range of applications.

Although being developed for the efficient manufacture of printing inks, entirely new fields of application in the digital and solar industries as well as in the high-tech industries gradually emerged over the years in collaboration with customers.

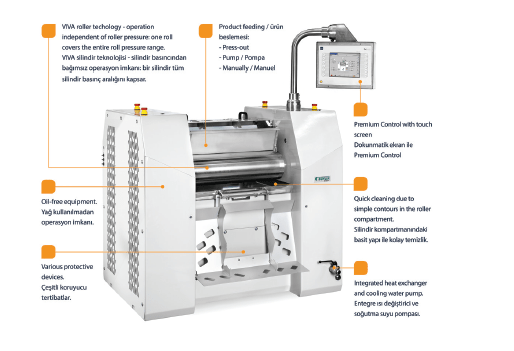

The experiences gained have been incorporated in the development of a new generation of three-roll mills based on an innovative machine design. The outcome of these efforts it the Trias machine series. Trias represents Bühler’s continuous commitment to further develop long-term established technology.

Reliability, high raw material yield and gentle dispersion of temperature-sensitive products are key properties of Bühler three-roll mills.

Bühler three-roll mills also show superiority over other technologies with regards to gloss properties of printing inks. Bühler solutions facilitate contamination-free processing of sensitive products.

Different roll materials and concepts permit clean room production according to international standards. In respect of operation reliability, the wide range of applications and resulting advantages for the production of pasty products, the Trias three-roll mill generation sets industry standards.

Maximum Throughput

Trias300 series has been designed for processing batch sizes ranging from less than one liter up to 75 liters per hour. The machine series next in size is the Trias600, which achieves hourly throughput rates between two and 150 liters. The Trias 800, further increases the throughput capacities of the series: Now, throughput rates as high as 300 liters per hour are possible.

VIVA – Unrivalled Roller System

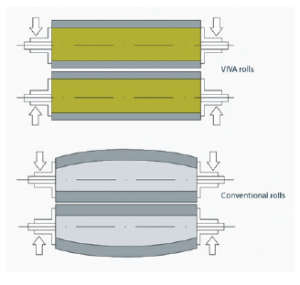

VIVA camberless three-roll mills operate reliably, even if requirements differ and with variable roller pressure. In contrast to conventional rolls, the Bühler VIVA roller technology is designed to be operated at different roller pressures and accordingly cover the whole pressure range.

VIVA camberless roller technology guarantees equal product quality along the entire roll length–independent of the roller pressure. As a result, comprehensive and easily repeatable product qualities are achieved and in so doing boost productivity.

The precise and powerful roller pressure unit generates linear load from 5 to 120 N/mm by this technology. Compared to conventional three-roll mills this range is significant wider for both low and higher roller pressure. Products, previously produced in gap operation can be processed in low roller pressure range (5 to 25 N/mm).

Improved Cooling

In addition to the well-known reliability and ruggedness of the machines, the most outstanding benefits offered by the new Trias include its high raw material yield and gentle dispersion of temperature-sensitive materials. The proven cooling system has once again been further refined and improved.

An enclosed cooling circuit equipped with an internal heat exchanger ensures optimal cooling even at high speeds. This allows the manufacture of the temperature-sensitive products in large batches.

The camberless VIVA roll technology provides a uniform product quality across the entire roll length, regardless of the roll pressure applied.

The Advantages

Maximum throughput;

• The Trias features extremely high roll speeds,

• A very wide roll pressure range can be used,

• Outstanding cooling capacity,

• Closed cooling circuit guarantees optimized cooling for temperature-sensitive products,

• Repeatable, constant product qualities,

• The automatic control of roll pressure and gap allows constant and repeatable product qualities,

• Products previously produced in gap operation can be processed in a low roll pressure range independent

of the operator,

• Safe and easy operation,

• High operator safety level according to the latest safety regulations,

• The data logging system WinTrend allowing process monitoring and thus supporting quality control.

Area Sales Manager (Turkey), Grinding and Dispersion Unit

Bühler Satış ve Servis Hizmetleri Tic. Ltd. Şti. (Bühler Turkey)