1. What is Filler?

According to DIN 55943, EN 971-1 and ISO 3262 part 1, filler is a substance consisting of particles which is practically insoluble in the application medium and is used to increase volume or to improve technical properties and/or to influence optical properties.

2. Why is a Filler Used in Paint?

Fillers are used in paint formulation:

• To control cost,

• To extend prime pigments (as a filler and extender),

• To improve or modify many functional properties of a coating powder.

Most filler are inorganic, usually in their fully oxidized state. They are heat stable, resist ultraviolet (UV) degradation and against chemical effects, and don’t interact with the binder system.

3. Mineral Fillers

3.1. Calcium Carbonate

Calcium carbonate is the most widely used white filler in paints because of its low cost, high brightness for TiO2 extension, high purity, low abrasivity, and resistance to weathering. PCC and ultrafine wet-ground grades contribute to rheology and stability and provide good dry hide and gloss retention.

3.2. Barite

Paints and primers represent the largest use for fillergrade barite (barium sulfate). High brightness micronized barite is used as an extender to provide the weight that customers equate with quality, and because of its low binder demand for high loadings.

3.3. Kaolin Clay

The principal use of kaolin in coatings is as a TiO2 extender. Partially calcined grades generally provide the best extension, durability, and dry hide. Water-washed and delaminated clays are used in water-based coatings to control gloss, film integrity, durability, scrub resistance,dicovering power, suspension ability, flow, and levelling.

3.4. Talc

Talc’s principal use in coatings is for sheen control. It also contributes to TiO2 extension, suspension stability, flatting, chemical resistance, film integrity and weatherability.

3.5. Wollastonite

Wollastonite is used in coatings as an extender pigment, and to provide resistance to flash and early rust. Its acicular nature imparts film durability and superior scrub resistance. Fine ground and micronized grades provide smooth flow, water resistance, improved wet adhesion and good gloss in epoxy powder coatings.

3.6. Diatomite

Diatomite is used to roughen the paint film to provide flatting and improved intercoat adhesion. It also improves film toughness and durability, and helps control

vapour permeability for reduced blistering and peeling.

3.7. Titanium Dioxide

Titanium dioxide (TiO2) is the most important white pigment used in the coating industry. It is widely used because it efficiently scatters visible light, thereby imparting whiteness, brightness and opacity when incorporated into a coating.

Titanium dioxide is commercially available in two crystal structures-anatase and rutile. Rutile TiO2 pigments are preferred because they scatter light more efficiently, are more stable and are more durable than anatase pigments.

Titanium dioxide pigments are insoluble in coating formulations in which they are dispersed; accordingly, performance properties, e.g., chemical, photochemical, and physical characteristics, are determined principally by the particle size of the pigment and the chemical composition of its surface.

3.8. Graphite

Natural graphite can be used in steel structure maintenance coatings due to its flake structure and good hiding rate. Its good conductivity and black colour make it suitable for use in electronic and computer electrical shielding coatings.

This coating can contain up to 75% graphite. Another use is anti-static floor coatings. It can be used in heat-resistant coatings, primers, sealing coatings and water-resistant coatings. Because of its good light resistance, it can be used in automotive paints as an effect pigment.

4. Ideal Filler Properties

Characteristics of ideal filler are:

• Inert;

* Noninteraction with binder system,

* Lightfast and colourfast,

* Resistant to solvents, acids, alkalies and chemicals,

* Heat stable,

* Insoluble in water and organic solvents distribution.

• Constant properties such as composition, particle size, and low specific gravity,

• Nontoxic and nonhazardous,

• Nonabrasive,

• Low cost.

Other important filler characteristics that affect the smoothness, texture, and gloss of a coating powder are as follows:

• Particle shape,

• Oil absorption,

• Specific gravity.

Particle shape affects gloss, smoothness, texture, and permeability of a coating powder. Oil absorption has a significant effect on flow and smoothness of a coating powder. Specific gravity also affects the coverage and applied cost of a coating powder.

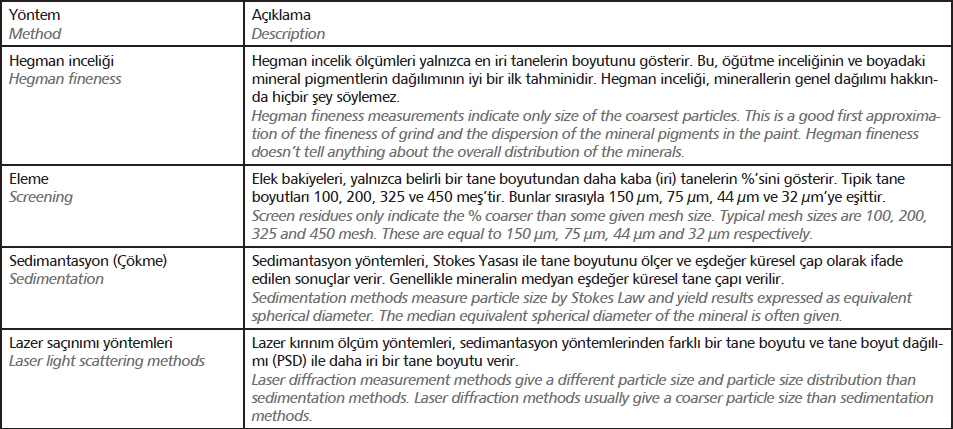

On the other hand, the particle size of a mineral can be expressed in several ways, depending on the method by which it is measured. Common methods of measuring particle size are:

• Hegman fineness,

• Screening,

• Sedimentation and

• Laser light scattering methods.

5. Conclusion

Many natural minerals are used in paint formulations due to their functional effects such as a filler and the volume extender and reducing costs. The contributions of these minerals to the paint, such as adhesion, barrier properties, opacity, gloss, resistance to chemical effects and corrosion, are important. Again, the particle shape, particle size, particle size distribution (PSD), density and oil absorption capacity of these minerals appear as filling properties that should be considered in practice.

Kaynaklar / References

1.DIN 55943, Colouring Materials-Terms and Definitions, 19 p., 2001. 2.Douglas S. Richart, Using functional fillers in coating-powder formulation, Powder Coating, February 1998. 3.EN 971-1, Paint and Varnishes-Terms and Definitions for Coating Materials- Part 1: General Terms, 33 p., 1996. 4.ISO 3362-1, Extenders-Specifications and Methods of Test-Part 1: Introduction

and General Test Methods, 6 p., 2020. 5.RT Vanderbilt Company, Inc., An Introduction to Mineral Fillers for Paints & Coatings. 6.VINCENTZ, Detlef Gysau, Filler for Paints, 3rd Revised Edition European Coating Library. 7.https://www.tipure.cn/-/media/files/tipure/legacy/titanium-dioxide-for-coatings.pdf rev=70975dd1245f4082841a13ef41058282 (18.10.2021) 8.https://www.european-coatings.com › Buecher (21.02.2022) https://coatings.specialchem.com/selection-guide/fillers-selection-for-paints-coatings (21.02.2022) 9.https://www.alpapowder.

com (21.02.2022)