1. Introduction

Wood Surface is one of the natural materials that it has benefited from since the existence of human beings. However, one of the most important reasons for that its ability to renew and a sustainable material.

Due to the fact that each wood species has its own aesthetic appearance, color, pattern, anatomical structure, these is a primary reason to prefer for many useful areas. Therefore, thousands of wood species have been used for many purposes throughout the world (Sahin and Mantanis 2016).

However, there is a number of reasons to choose wood as material for many uses such as; a light and durable material that its processing very easy with low energy requirements, dry wood show insulating property with having suitable resistance and mechanical properties for many construction works and so on.

Some of the examples of its as construction and housing works, furniture and decorations, energy and industrial products (Bowyer, et al. 2003). In spite of the many advantages mentioned above, wood has also some important disadvantages that this has a limiting effect on many applications.

Since the wood is an anisotropic material that shows different physical properties in three directions (transverse, tangential, radial). However, because of hygroscopic in nature, it can lose or gain moisture from the atmosphere.

In addition, due to their natural nutritious ingredients, they can be destroyed by organisms such as fungi, insects and bacteria (Bowyer, et al. 2003; Kubler, 1980).

In addition to the properties as described briefly above, one of the most important disadvantage of wood use in furniture and decoration works, it could be easly degraded by atmospheric conditions (weathering) so its natural aesthetic appearance may be impaired.

The weathering effect could be solar radiation (UV rays), humidity (rain, snow, moisture, dew) and mechanical effects (wind, sand, clay). As a result of these degredations, wear, roughness and cracking may occur on surfaces which may lose their natural appearance (Bowyer, et al. 2003; Feist, 1983).

2. Wood Varnishes

One of the most effective ways for protection of natural texture of wood material is that by applying transparent surface treatments. This could be done the application of varnishes to wood surfaces. However, after drying and hardening, a transparent layer could be formed.

Varnishes are transparent surface treatment agents that typically consists at least two elements (solvent and solid matter) as in the solutions (Kurtoglu, 2000).

The primary aim of application varnish to wood surface is to preserve the natural aesthetic appearance of color by creating a protective layer on the wood surface. However, varnishes can be classified in many ways (Kurtoğlu, 2000; Sönmez and Budakçı 2004).

Most generally;

• According to drying and curing conditions (physically, chemically, combination of both hardenings),

• According to the effect on the surfaces (glossy, matte, transparent),

• Depending on the place of use (furniture, decorative,

water vehicles),

• According to the characteristics of the solid polymeric

materials (alkyd, urethane, cellulose),

• The application order (pre-layer, topcoat, filler).

It is important to make the right choice in forming a protective layer in accordance with the end use of the wood material. Generally, the most commonly used varnish types are two-component solvent-based (oily varnishes) that hardened combination of both physically and chemically.

However, as a result of the volatile organic compounds (VOC) released (emission) to atmosphere during the preparation or uses, it is needed to utilize more environmentally friendly varnishes. Hence, many varnish types with different formulations have emerged in recent years.

As a result of these researches, the water based (waterborne) varnish systems have become increased gradually in recent years (Kurtoğlu, 2000; Sönmez and Budakçı 2004; Ulay and Budakçı, 2015).

2.1. Waterborne Varnishes and General Properties

As described briefly at above, varnishes are solutionsthat consisting at least two different (solventsand solid matter) members. The solvents have usuallyused as soluble matter in formulations.

However,the solvents could be released (emission) some volatileorganic compounds (VOCs) to the atmosphere,during or after applications from the surface of thewood material.

These adversely affect human andenvironmental health. In recent years, many studieshave been carried out especially on the reductionof solvent use in varnish systems with lowering VOCemission to athmosphere (Kurtoğlu, 2000; Ulay andBudakçı, 2015).

As a result of these studies, waterbasedvarnish systems (waterborne) that containingvery low levels of volatile organic compounds havebeen prepared from various polymers (Kurtoğlu,2000; Sönmez and Budakçı 2004; Ulay and Budakçı,2015).

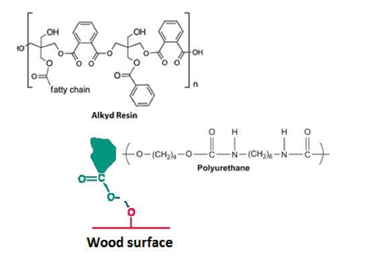

In this regards, waterborne varnishes are generallyproduced from resins such as alkyd, polyester, acrylicand polyurethanes. However, transparent waterbornevarnishes do not contain color pigments but indull types, some elements added to ensure matting(Kurtoğlu, 2000; Sönmez and Budakçı 2004; Ulay veBudakçı, 2015).

After the removal of water (hardening) from the suspensionthat small polymeric substances dispersed,then the polymeric particles combine with the surfaceof the wood to form a thin transparent film.

Theresins used in the preparation of these varnishes alsocontain functional groups such as hydroxyl (-OH),carboxyl (-COOH) and amide (-CONH2) with the longcarbon chains (-R). These groups are connected betweenmolecules by reacting at free functional groups(-OH) on wood surface (Fengel and Wegener, 1984;Sönmez and Budakçı, 2004).

Figure 1 schematicallyshows the chemical structure and bonding of alkydand urethane resins with wood surface.

After a number of researches conducted on waterborne varnish systems, the use of that varnish at woody materials have been increased in recent years.However, waterborne varnishes are one of the varnish systems that provide protection and transparency closest to the natural color of the wood.

Since they harden both physically and chemically, therefore they can be forming a durable layer on the surfaces with easily application-repairment and mark free on surfaces.

The waterborne varnishes are usually created fewer resistant layers on wood surfaces than other solvent based varnishes (Kurtoğlu, 2000; Ulay and Budakçı,2015).

Because of moderate adhesion to wood surfaces,appropriate hardness and the ability to forma thick and protective layer is not easy. This is dueto its low solid content with special chemical properties that adversely affect the reaction.

The waterbone varnish’s pH level in usually in alkali level (pH:8-10), it could be caused some discolorations on some wood surfaces (i.e. tannin for oak) (Ulay andBudakçı, 2015). Table 1 shows the general properties of water-based varnishes.

| Advantages | Disadvantages |

| The proportion of volatile organic compounds in chemical formulations is low. |

Multiple layers must be formed to provide effective protection on wooden surfaces. |

| During their use, there is almost no emission of volatile organic compounds (VOCs) into the atmosphere. |

In outdoor atmospheric conditions, protection factors are generally lower. |

| They can be used for softwood and hardwood species | As it is alkaline, it can react with some wood compounds (tannin). |

| They are easy to apply and clean. | The degree of bonding to wood surfaces is moderate. |

| They can provide protection without changing the natural color of the woods |

Hardening/Drying times are longer than chemical drying systems. |

| They are cheaper than other varnish types. |

3. Conclusion and Recommendations

One of the best ways to maintain the natural appearance of wood is to use synthetic varnish. However,many varnish types other than waterborne can produce more or less color change on the surface of the wood material.

In this respect, there has been a rapid increase in the application of waterborne varnish systems to wood products in recent years. This is mainly due to the development of the properties of binder resins, which allow it to be formulated in different properties, and to avoid the emission of toxic chemical into the air due to its formulation.

Because,in the structure of other varnishes, volatile organic compounds (VOC) are generally present and VOC is mixed with air during the application and/or use of the varnish.

Although varnish manufacturers use some chemicals in their structures to keep the VOC level at a limited level, water-based varnishes contain much less VOCs than oil-based ones and are therefore much safer.

Prof. Dr. H. Turgut Şahin – Isparta Applied Sciences University – Forest Faculty – Department of Forest Industry Engineering

Sevim Yılmaz – Forest Industry Engineer – Isparta Applied Sciences University – Forest Faculty – Department of Forest Industry Engineering

Gamze Özçelik – Forest Industry Engineer – Isparta Applied Sciences University – Forest Faculty – Department of Forest Industry Engineering

İsmail Erbil – Forest Industry Engineer – Isparta Applied Sciences University – Forest Faculty – Department of Forest Industry Engineering