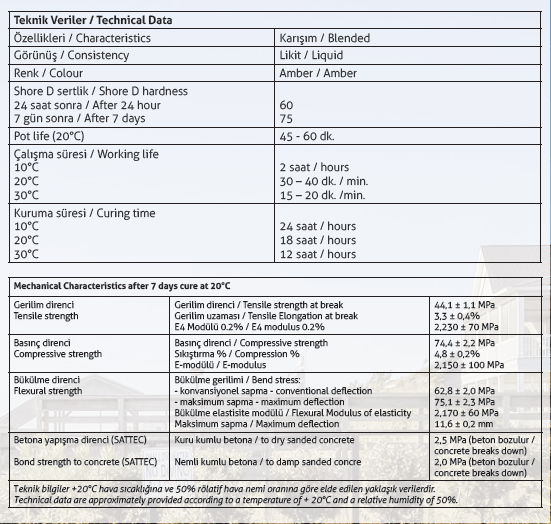

Product Description

Bostik Smart Primer Eponal 336 is a solvent-free, twocomponent epoxy primer with excellent chemical and mechanical resistance. The biggest difference that distinguishes it from other products on the market is that it also allows application on wet surfaces (except ponding).

A solvent-free, chemically and mechanically resistant, two-component epoxy primer that is suitable for use as a bonding primer on damp concrete subfloors or before epoxy applications which are likely to suffer later from rising damp.

Smart Advantages

– Solvent-free,

– Hemically and mechanically resistant,

– Two-component epoxy.

Areas of Application

Interiors and exteriors, normal and very absorbent surfaces,

new and old all cement based subfloors, all mineral- based floors e.g. concrete, tile, ceramics, stone, etc.

Features

Forms a strong, uniform and continuous coat regardless of the surface moisture content. Resistant to hydrostatic pressure (up to %100). Does not shrink. Can be used to flatten the surface prior to industrial coating and floor paints. High-resistant. Low VOC. Water and moisture resistant forms a protective barrier.

Preparation of the Substrate

The surfaces to be coated should be free of adhesive preventive foreign substances such as dust, dirt, mould oil, paint etc.; residues and wastes like cement, plaster and concrete should also be removed.

The subsurfaces that are not strong enough to bear their own weight e.g. cracked plasters, weak surfaces, or residues of moss should be cleaned from the application surface.

It should have adequate compression and tensile strength (respectively at least 25 MPa and 1,5 MPa after 28 days cure for new concrete) and should not be exposed to hydraulic pressure. Depending on surface condition and type, substrates are treated by abrasive blasting, mechanical planning, scabbing, sandblasting, high pressure water washing or chemical stripping.

After mechanical treatment of a subfloor, thoroughly vacuum all dust. The floors which require repair should be filled with special repair and cast mortar at least 7 days before adhesive application.

Application Application with a Roller

Eponal 336 epoxy primer resin is slowly added on the hardener while mixing thoroughly with a low-speed mixer until obtaining a homogenous colour and mixture.

The freshly obtained mixture should be used within 30 minutes. Studded shoes should be worn to be able to walk on the fresh resin layer. Use a spiked roller to help aeration and to avoid bubbles inclusion.

After Application

In the first days, newly applied surfaces should be protected from direct sunlight, severe air stream, high temperatures (over +35°C), adverse air conditions such as rain and frost. After application, clean the hand tools with water or MEK (Methyl Ethyl Ketone) immediately.

To obtain the recommended long term technical performance of the product, after the completion of the all application, the application and/or work should be covered and protected with a suitable coating or covering (screed, ceramic, tile etc…) as early as possible (depending on the product’s drying time within 3-7 days).