Environmentally Conscious PTFE Micropowder Usage in Coatings

In recent years, growing concern over PTFE usage has spurred regulatory changes and public reproach. Shamrock has addressed these concerns through PTFE waste recycling and mitigation of PFOA levels in production and final products. [1] The Shamrock Chemicals

Corporation is formed in 1951 as a subsidiary of the William D. Neuberg Company, concentrating on the sale of powdered waxes. Shamrock European headquarter in Tongeren opened in 2001.

This is followed by the opening of its Tianjin plant in China in 2004. A third plant is built in Kentucky in 2007. Shamrock’s worldwide manufacturing facilities now top more than a half million square feet in six facilities across three continents. [2] With this article you will understand how we reduce our environmental impact.

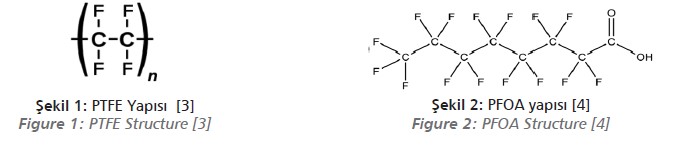

PTFE is a unique polymer utilized in many applications. This polymer is known and valued for its unique properties, such as increasing slip for can coatings and improving abrasion resistance in inks. Its temperature stability makes it a valuable additive for high-temperature applications including coil or powder coatings.

The particles maintain their shape and performance even above 250°C. [1] PTFE is one of the strongest polymers due to its very stable C-F bond, which imparts some amazing properties. In the last two decades, PTFE has become a subject of environmental and health concerns due to the additive used for its polymerization, PFOA (perfluorooctanoic acid).

PFOA is classified as a “forever chemical” due to its biopersistence and has been banned from continued use in the polymerization process. Alternative agents have been developed

to facilitate such polymerization. [1]

Recycled PTFE and Reduction of CO2 Emissions

Shamrock has recycled more than 150 million pounds of PTFE, saving an estimated 1.5 billion pounds of CO2 emissions and a huge amount of unusable, environmentally persistent waste product. Shamrock has found that using 1 kg of recycled PTFE instead of virgin PTFE will eliminate at least 10 kg of CO2 emission. [1]

The industrial-scale production of the virgin polytetrafluoroethylene (PTFE) polymer involves several stages [1]:

1. First, calcium fluoride (fluorspar) is reacted with sulfuric acid to form anhydrous hydrogen fluoride, the key source of fluorine for subsequent reactions.

2. The other starting material, tri-chloromethane (chloroform), is made by reacting methane with elemental chlorine.

3. The chloroform is then partially fluorinated with anhydrous hydrogen fluoride to produce chlorodifluoromethane (CHClF2, also called R-22), which is then pyrolyzed to become tetrafluoroethylene (TFE).

4. Polymerization of the TFE monomer is carried out under carefully controlled conditions to form the PTFE polymer.

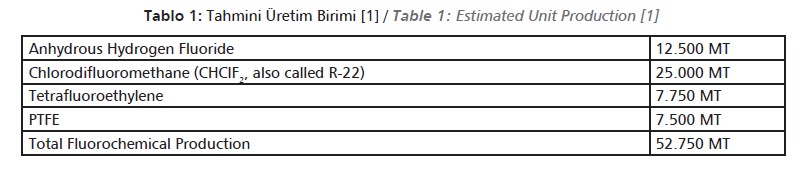

A model PTFE manufacturing plant, based on current sites in the US, was studied to estimate the CO2 emission of PTFE production. The following calculations show the amount of CO2 produced in its production of PTFE. [1]

Estimated energy consumption of model fluorochemical production plant:

Basic informations for calculations: 761 kWh/MT fluorochemical production + 96Therm* Natural Gas/MT fluorochemical production [1], Therm = non-SI unit of heat energy equal to 100.000 British thermal units (BTU) or 29.3 KwH, approximately the energy content of 100

cubic feet (2.83 cubic meters) of natural gas at STP. [1]

Based on these figures, estimated total energy consumption for PTFE production:

Electric Energy: 761 kWh x 52.750 MT total production / 7.500 MT PTFE production= 5400 kWh/MT PTFE Natural gas: 96 Therm x 52.750 MT total production / 7.500 MT PTFE Production= 680 Therm/MT PTFE Based on the energy consumption estimated above, the

required amount of electric energy and natural gas can be converted to equivalent CO2 emissions. [1]

CO2 emissions from electric energy:

5400 kWh/MT PTFE x 1.10kg CO2eq /kWh= 5900 kg CO2eq / MT PTFE or 5.90 kg CO2eq / kg PTFE

CO2 emissions from natural gas:

680 Therm / MT PTFE x 8408 kg CO2eq / Therm= 3700 kg CO2eq/MT PTFE or 3.70 kg CO2eg / kg PTFE Total: 9.6 kg CO2eq /kg. For every recycled kg of PTFE, almost 10kg CO2 emissions can be eliminated.

PFOAs in PTFE Micropowders

PTFE micropowders (used in inks and coatings applications) need lower molecular weight (MW) to be processed to their desired size. MW is lowered through the degradation of a high MW (MW) PTFE resin. The degradation mechanism utilizes thermal or radiationinduced

processes. [1] PFOA and other chain length organic acids are a result of degraded PTFE products.

The European Union put forth a REACH regulation (EC) No:1907/2006 requiring a PFOA concentration under 25 ppb in PTFE micro-powder which took effect on July 4, 2020. April 8th, 2020, the timeline was extended by POP Regulation (EU) 2019/1021 (as amended by Commission Delegated Regulation (EU) 2020/784), which allowed for PFOA concentrations up to 1000 ppb, until July 4, 2022.

Meanwhile the European Council extended the 1000 ppb limit, the decision on further limiting PFOAs down to 25 ppb has been postponed.[1] Companies looking to sell in European markets must reduce their PFOA footprint. Shamrock launched the “RC” PTFE

micro powder series to ensure conformance with the more stringent <25 ppb regulation.

Conclusion

At Shamrock seeking sustainable solutions and leave a smaller environmental footprint. Their business is centered around sustainability; Shamrock products both reduce PFOA and carbon footprint through PTFE recycling and rigorous production standards.

References

1. Shamrock “Environmentally conscious PTFE micropowder usage in coatings”,2022,

2. Shamrock Technology, https://shamrocktechnologies.com/,2017, 3. Wikipedia, https://tr.wikipedia.org/wiki/Teflon, 21.04.2022, 4. Wikipedia , https://en.wikipedia.org/wiki/Perfluorooctanoic_acid ,06.09.2022

Dr. Hyun Seog Kim – Ph.D. Chemical Engineer

Technical Service Group Manager

Shamrock Technologies

Eliz Türkileri – Chemical Engineer

Senior Technical Sales Executive

Ravago Chemicals Turkey