Functional Silicones for Easy-to-Clean Coatings

Introduction

Coatings are ubiquitous and vital in protecting and decorating substrates. Good adhesion on substrate, durability, and resistance to damage from environmental exposure are the basic requirements for most coating systems.

Recently, there is a growing interest in coatings that can provide noteworthy functions in

addition to the traditional features. These coatings, often called “functional” or “smart” coatings, can help provide additional value to end users.

One of such sought-after functions is “easy-to-clean” which is highly desired for construction/architecture, automotive, and personal electronics. In order to repel stains or make stains easily removable, such coatings need to have low surface energy and, ideally, a combination of hydrophobicity and oleophobicity.

Silicone and Fluoro materials are well known for reducing coating surface energies. Often, both are used to achieve the best easy-to-clean effects. As concerns are growing about the environmental and health damages that fluoro chemicals can potentially cause, people are now searching for nonfluoro solutions.

Functional silicones, thanks to their lower surface energy and versatility, are excellent

candidates to replace fluoro chemicals for easy-toclean coating applications.

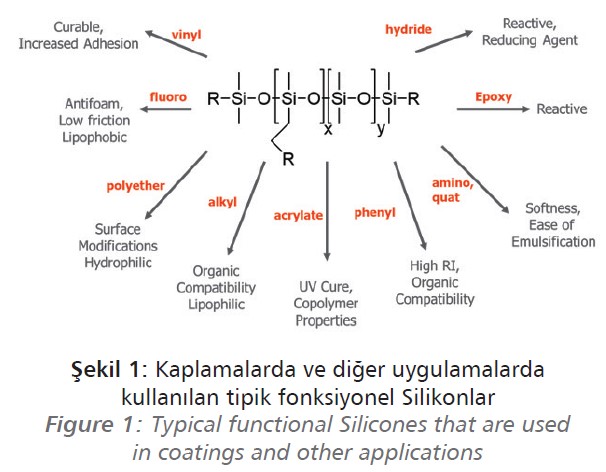

Different from traditional Silane/Silicone oligomers or polymers, functional silicones have one or more organic functionalities that can bring in various performance benefits as well as help improve compatibility in different coating systems (Figure 1).

In this paper, we will introduce a functional Silicone CoatOSilTM CLEAN, that can deliver

easy-to-clean properties in Acrylic paints.

Easy-to-Clean Solution for Waterborne Acrylic Latex Paint

This study was to investigate additives’ effects on the non-staining or easy-to-clean performance of interior architectural paints against common stains sources, such as scuff marks from physical rubbing of objects against the wall, surfactant leaching, and other household stains.

Model Formulation and Test Methods

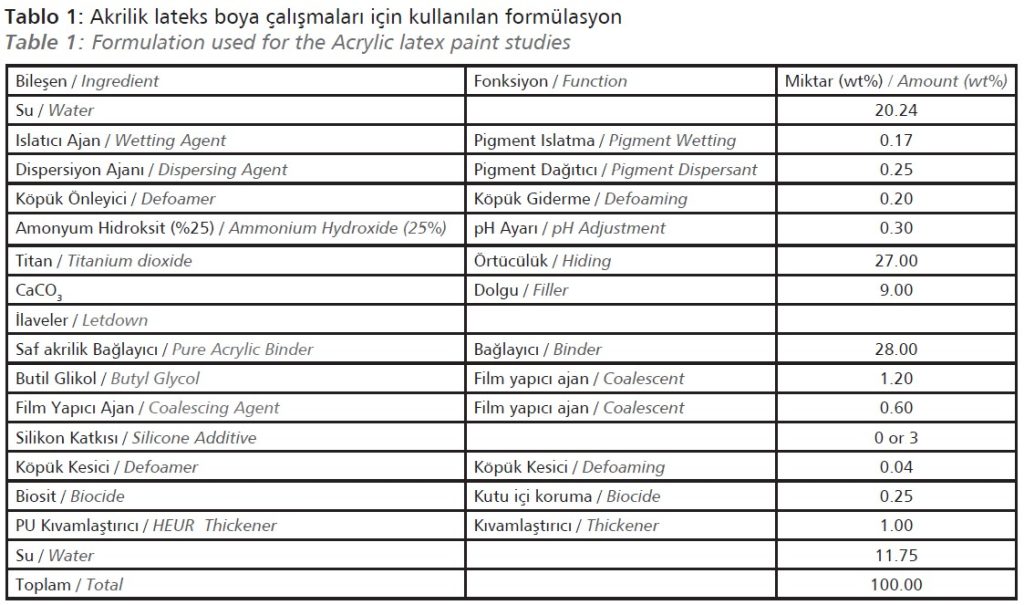

A semi-gloss formulation shown in Table 4 was used to evaluate different additives from Momentive. A commercial pure acrylic latex was used as the binder of the base paint. Each silicone additive was post-added into the base paint at 3 wt% loading level based on the total formulation.

Standard ASTM methods used in this study were included in the result section. For scuff resistance, an inhouse test method was used. Different materials like rubber cork, pen cover and metal spatula were rubbed manually on a fully dried paint surface with moderate

pressure.

Equal pressure and rubbing duration were used for all paint samples, and then the marks and stains generated on the surface were rated. Water dynamic contact angle and oil dynamic contact angle were measured using a Thermo Cahn DCA 322 microbalance. A paint was applied with a sponge applicator on both sides of a Leneta black scrub test

panel (1’’ X 1.5” rectangular).

The dry paint film thickness was around 50 microns. The speed and the total depth of the sample immersion were 80 microns/sec and 8 mm respectively. The initial surface tension of water was measured with a platinum Wilhelmy plate and was equal to 72 mN/m.

The oil used for oil contact angle was soybean oil Agri-Pure 25 from Cargill. The surface tension of soybean oil was 33 mN/m. Dynamic coefficient of friction was measured using a

CSM tribometer with a linear reciprocal stroke of amplitude 0.5 mm, stainless steel ball (5 mm diameter), 2 N load, and sliding speed of 1 cm/s.

Results and Discussion

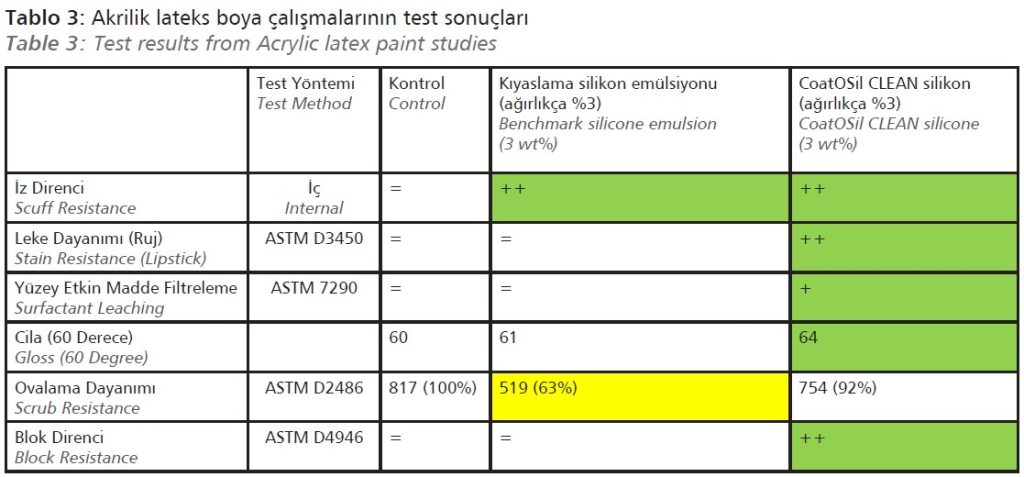

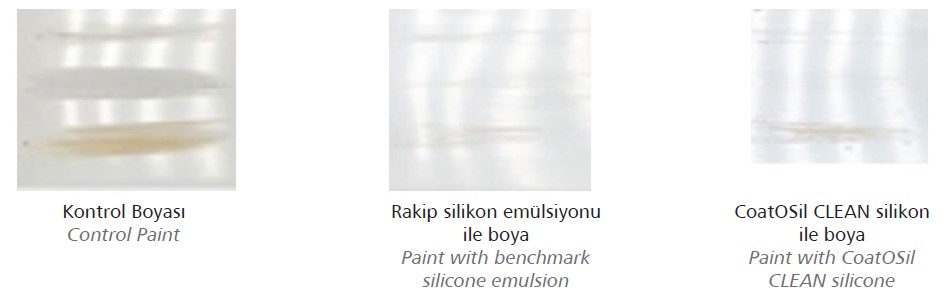

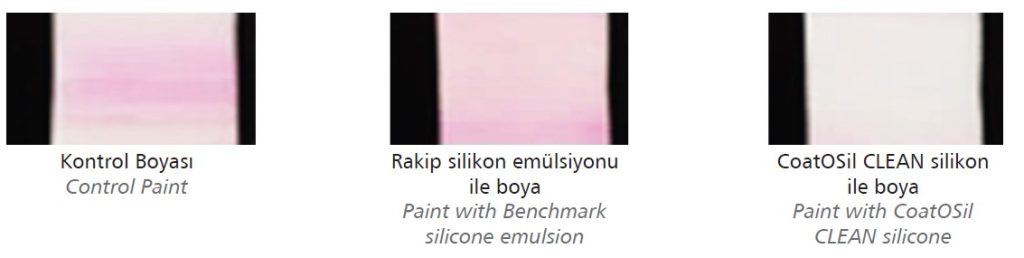

Results of the easy-to-clean and other paint performance properties are shown in the Table 3. As shown in Figure 3, the CoatOSil CLEAN silicone containing paint looked significantly better than both the control paint and the benchmark silicone emulsion containing paint.

The same trend was seen in the surfactant leaching test where water streak marks on CoatOSil CLEAN silicone containing samples was the least (Figure 4).

Figure 2 shows results from the scuff resistance test. Both Benchmark silicone emulsion and Coat- OSil CLEAN showed significantly less scuff marks from rubber cork, metal spatula and pen cap, than the control paint.

Figure 2: Scuff resistance results in acrylic latex paint with and without different Silicone additives (top: pen cap, middle: metal spatula, bottom: rubber cork).

Figure 3: Lipstick stain removal results in acrylic latex paint with and without different Silicone additives.

Figure 4: Surfactant leaching stain resistance results in acrylic latex paint with and without different Silicone additives.

Overall, CoatOSil CLEAN silicone performed the best in resisting stains from scuff, lipstick, and surfactant leaching. In addition, it increased gloss and improved anti-blocking (shown in Fig 5), without a negative impact on scrub resistance.

These improvements can be attributed to its proprietary functionalities on the Silicone backbone. Its unique structure provided the paint surface a balanced combination of hydrophobicity and oleophobicity, as well as reduced coefficient of friction.

Dynamic contact angle and advancing contact angle measurements were used to

demonstrate these effects. As shown in Figure 6, water and oil contact angles of CoatOSil CLEAN siliconecontaining paint were significantly higher than those of the control/base paint.

Also, coefficient of friction of the base paint and CoatOSil CLEAN silicone containing paint were 0.3 and 0.16, respectively. This study showed that CoatOSil CLEAN silicone could significantly help improve the easy-to-clean properties of a paint by increasing the slip and reducing surface energy of the paint surface.

Conclusion

In the waterborne latex paint study, a new additive from Momentive, CoatOSil CLEAN silicone, resulted in best overall performance in scuff, stain and surfactant leaching and block resistance.

This study showed that CoatOSil CLEAN silicone could significantly help improve the easy-to-clean properties of a paint by increasing the slip and reducing surface energy of the paint surface.

Contributors:

Dmitry Chernyshov, Rosemeire Ciro, Anne Dussaud, Yogesh Tiwary Ning Lu, Christine Lacroix*, Michaud Hélène* *Momentive Performance Materials

Writer:

Hélène Michaud – Application Development Engineer

Momentive Performance Additives

Technical Contact:

Hakan Askun – CASE Laboratory Manager

Azelis Turkey