The ideal paint application solution? All SAMES KREMLIN solutions answer this question that many customers ask themselves. HVLP or Conventional, Airmix®, Airless® (*), Electrostatic, Powder coating, many technologies are available to spray paint on parts.

It is very complicated for a production manager to find his way around. Spraying technology must be perfectly adapted to the customer’s production. The elements are numerous.

What type of application do we do? Is it a protective or embellishing application on the part? On visible or non-visible parts? Complex or simple design parts? What type of substrate – metal, plastic, wood? On high or low production volumes? So many questions for a project manager.

SAMES KREMLIN offers a whole range of solutions to be as close as possible to the customer’s needs.

Protecting a part requires paints with high chemical characteristics or charge. This does not require a perfect finish quality. A typical example would be the application of paint in the field of bridges and roadways or on oil pipelines.

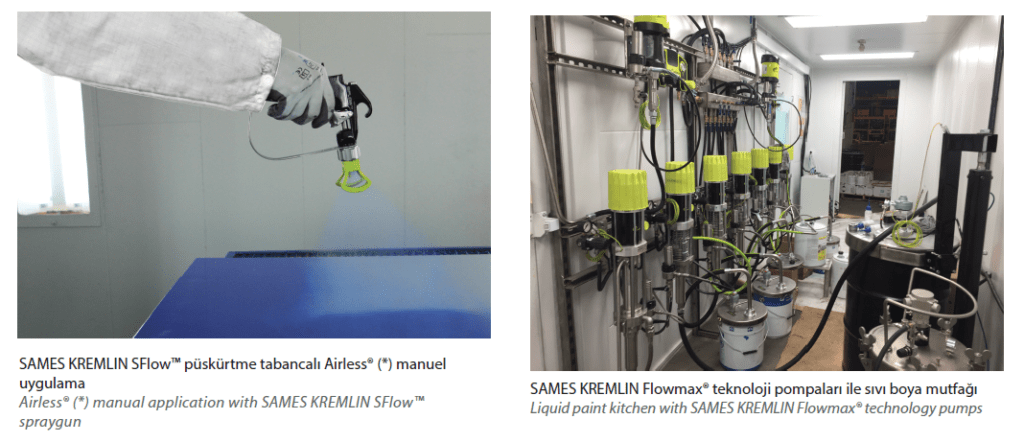

The ideal solution in this case is the one that allows an optimized investment, so Airless® (*) technology should be preferred. SAMES KREMLIN’s Airless® (*) solutions bring real added value in a world where it is fashionable to say that only spraying paint is enough.

Well, no! There are many cases where protecting a part requires a very high level of control and atomization quality. Especially for paints whose cost is very high and which have chemical or mechanical qualities allowing very long durability.

Whether in mono- or multi-component form, only the quality of transfer, dosing or application will make it possible to comply with the specifications on the level of protection or durability.

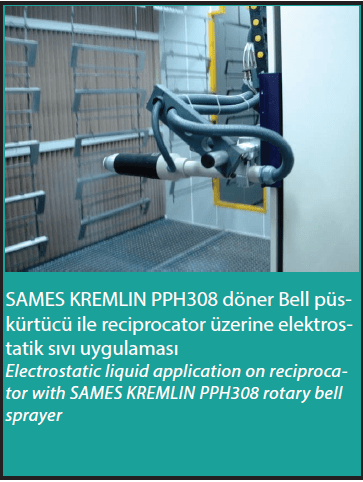

Embellishing a part requires much more complex characteristics, in terms of atomization quality but also in the applicator’s ability to maintain this level of quality even if production is very high. For productions requiring a very high quality finish and very high gloss, there is no choice but to turn to two types of technologies: pneumatic technology or electrostatic bell technology.

These technologies have the most beautiful finish because they are the ones that atomize the paint the most finely. SAMES KREMLIN solutions of the Airspray HVLP or Conventional type, or even hybrid solutions such as Airmix® technology in certain markets such as the Wood market, allow high-end finishes with very high productivity.

Painting visible or non-visible parts is a very important entry point for a customer because it implies that the paint he will apply on non-visible parts will rather be a protective paint that will require an Airless® (*) type solution, or even Powder coating.

A visible part, on the other hand, will require a higher level of finish and will require solutions such as Airsray or Electrostatic Bell. Painting complex parts increases paint cycle times and significantly reduces productivity if the choice of solution is not the right one.

Transfer rates are also likely to be very low and consume a lot of paint. Additional technologies to existing technologies help to address these difficulties in the application of paint to protect or beautify parts.

Electrostatic technology is one of them. It allows the paint to charge electrostatically and use magnetic fields to naturally go around the part. For example, a tube can be painted in one go with electrostatic technology compared to about ten times without.

However, this productivity requires more complex installations when waterborne paint is applied and higher skills for the painter and equipment maintenance. But the gain in terms of paint consumption and productivity is worth asking the question for a production manager.

On less complex or flat parts, we will clearly talk about protection, finishing and productivity. As a result, many technologies are available and it is really complicated for a production manager to get an idea of the ideal solution.

In this case, we must go back to basics. If I apply protective paints, their high viscosity or filler characteristics will make it more likely to use an Airless® (*) type technology. For productivity and finishing or embellishment needs, it is better to choose hybrid technologies such as Airmix®.

Indeed, these technologies combine high quality finishing with high outputs. If the part is made of metal, it is best to add additional electrostatic technology. On flat metal parts, the transfer rate can reach up to 98%! The paint transfer rate: this is a term that is difficult for customers to understand.

In concrete terms, if on 1 litre of sprayed paint, the painter applies 0.6L of it on the part to be painted, the transfer rate is 60%. SAMES KREMLIN’s entire approach from a technological point of view is to combine the finest atomization of the paint with a transfer rate as close as possible to 100%. That is to say, to offer both finishing & productivity.

As part of the most widely used application technologies in the field of painting, SAMES KREMLIN has always imposed its technologies through patents and, above all, through very significant customer experiences.

From the creation in Europe of the first pneumatic paint gun, to the invention of the Airmix® hybrid technology, the creation of the SKILL™ Airless® (*) technology and the perfect mastery of Electrostatic technology, whether on guns or bells,

SAMES KREMLIN is a company that provides its customers with concrete paint savings AND a very high level finish. There can be no derogation from this principle. Our presence with the largest Automotive manufacturers or with the most prestigious customers in the Wood, Metal and Plastics markets testifies to this.

Christophe Denis Bosio – Global İletişim Müdürü – Global Communication Manager – SAMES KREMLIN