Paint, chemistry (Construction chemicals, adhesives, pharmaceuticals, agricultural products, etc.)

Coating products, which show significant development both in our country and in the world, bring along the need for development in the machinery and equipment where these products are produced.

As Sözer, we are not only a company that provides machine supply also we can produce professional solutions according to your needs with our 73 years of experience and the knowledge. We have acquired in line with our exports to 52 countries as of today.

We can establish and create your turnkey project works, fully automated, semiautomated and manual operating systems with our significant experience. These types of projects can be done within our company based on advanced technology and high efficiency engineering.

With the development of the industry, progressing machine technologies make it necessary for the existence of effective and powerful design mixing machines. You need to have the right recipe and the right machine and equipment group in order to be successful in the field of quality and time.

This is directly proportional to how you control your product and the production process. In general, chemistry can sometimes become very complex as a result of the reaction, which appears to be very easy but with the combination of various components.

For example, you can produce “Caulking Compounds” on the “Planetary Malaksor Machines” which is a heavy paste type and has 500.000 centipoise. The more effective choice for a product in this viscosity is “Zet-Kneader Machines”. This is exactly what we are talking about, “Choosing the Appropriate Machine”.

Our single mixing shaft machine systems and planetary malaksor machines have been serving successfully for many years. In addition to these machines, our combined mixers with two or three spindle systems and combined planetary malaksor machines have been in serious demand in recent years.

The target customers of our machines within this scope

Are the companies that produce products in the range of 5.000 – 3.000,000 centipoise. If the substances in these products can only be mixed into the product by dispersion, they need a fast mixing propeller on the machine.

In order for this mixer to disperse, it should be 19-25 m/sec. There should be dispersion propellers that can reach the environmental speed. There may also be cases where only a high-speed dispersion is not sufficient for mixing high or low viscosity products.

Blending can be carried out homogeneously in very short periods with two pallet systems with a separate speed adjustment system which can operate independently of the fast speed system in the process. This mixing device can also be integrated with scraper and vacuum systems.

Depending on the viscosities, both the design and features of the vertical mixers have to be changed. When a batch becomes too viscous, high speed mixer with a fixed axis of rotation will not finally produce sufficient flow, resulting in weak product homogeneity.

Due to hav- ing two features, combined planetary mixer machine distinguishes from the other vertical mixers. The first and the most important feature is that the two planetary shafts with angled blades rotate on their own axes while they orbit on a common axis.

Because of the advancing blades through the batch, the blades continuously move through the batch irrespective of product flow. The second feature is to have a high-speed shaft which is mandatory for some formulations. High speed shaft with sawtooth impeller is very effective at powder wet-out and performing dispersion.

In addition to these two shafts,

The combined planetary mixer has also another shaft called as scraper arm which helps agitation process by removing material from the wall to the center.

You can produce pigment paste, petrochemical products, insulation and filling materials, putty, pastry, sealing products, silicone, mastic, sealing components (etc.) easily in a very short time with combined malaksor machines. Due to the dispersion propellers, blade profile and peripheral speed, they can create some heat on the material.

PT100 heat meter system is used as a standard feature in these machines in order to prevent the deformed product from entering the reaction with the temperature of the product or to follow this temperature curve. Cooling motors are also coupled onto the main motors.

That’s allow long-time operation at low revolutions, which come standard with the machine. In combined mixers, besides the features like scraper, vacuum, pressure, PT100 systems, there is also a time-based mixing feature as standard.

These types of machines require very powerful motors and equipment, according for that machine bodies are manufactured completely castings. Starting from laboratory types capacity, they can be produced with capacities of 10, 500, 1.000, 1.500, 2.000, 3500 and 5000 liters.

The casting of the machine’s body ensures its lifetime wear and rigid operation. Except machine functions, there is digital temperature display screens for individual mixing motors, amps, timer digital displays and the temperature of the produced product at the operator panel.

Apart from this, half or fully automatic recipe control system,

PLS control system feature is offered as an optional feature in the operator’s panel.In mixers, the transmission organs are very important, especially in such machines where there are a lot of mixing systems. Your machines should be designed to be of the right type and serving the purpose.

The engineering calculations are very important at this point. Incorrect designs, mispredicted powertrains may cause incomplete transmission of power, mixing equipment from the motor. You can see too powerful engines at these types of machines.

Because some companies think that they will close faulty designs by choosing a powerful engine.

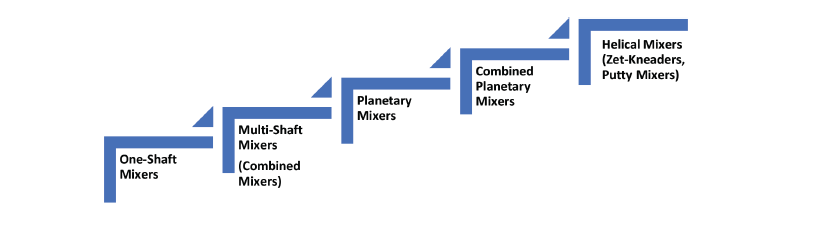

Mixer should be selected from the left to the right with the rising viscosities. Choosing the right machine doesn’t just mean the machine type. You also need to do your benefit / cost analysis correctly.

Especially in recent years;

İn line with the importance given to innovation by companies, automated systems are in high demand. Therefore, it is aimed to complete production processes in an automation system that extends as much as possible from manpower to packaging.

As Sözer Makina, we can offer you solutions with fully automatic or semi-automatic systems in accordance with your request from the beginning to the end of the system. By adapting the new generation powder or liquid raw material feeding systems to our machines, it is ensured that raw material feedings can be measured and appropriate.

Afterwards, we can ensure that the production process is transferred to the silos or filling line after the completion of the production process on the appropriate machines with our fully automatic or semi-automatic systems.

We can program the software infrastructure of our machines in accordance with your prescription structure in line with the software systems prepared by our own team. In this way, we ensure that you have a sustainable and standard structure.

Currently in Turkey, we are the most capable of producing a wide variety of machines firm in our own industry, at this point in the world of today also we are one of the leading companies in the industry with our machines.working in 52 different countries. We see this success especially as an indicator of our quality in exports.

We keep ourselves open to constant updates with all our staff. Within the scope of our facilities, we receive ongoing trainings in terms of engineering and production, and provide our staff with opportunities to follow the developments in their respective branches in the world.