Self-Healing / Self-Repair Coatings

Summary: General information (i.e. history, terminology) along with the main types, trends &new advances and the advantages/disadvantages about the Self-Healing /

Repairing Paints and Coatings, which is a new and groundbreaking class of paints/coatings in the fields of Industrial, Marine, Aerospace, Automotive, Conformal and Textile, are summarized in this article.

1.Introduction

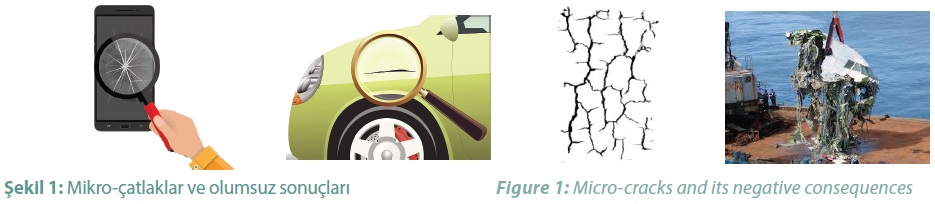

Things like scratching and cracking can happen. We take them as a part of life! For example, you can drop your mobile phone off the ground and scratch its screen or even break it. What is even worse is that your car is scratched or cracked.

You can’t say the same for repairing your car paint case since the money and time you will be spending on repairing your cell phone case is relatively low!

Even worse case is, invisible micro-cracks occuring on the critical equipment and structures due to As an example, in 2002 the 22- year micro-cracks in the hull of the Chinese Airlines 611 flight have break-up the fuselage leading the plane falling into the sea off Taiwan!

However, just like you gently cut your hand, the bleeding area will clot and self-heal (repair the body) after a certain period of time. Using the same mechanism, Self-Healing / Repairing Paints and Coatings may bring in self-healing / repairing functions to the metal, wood, concrete, composite and even textile surfaces.

Figure 2: Blood coagulation and self-healing of skin

Figure 2: Blood coagulation and self-healing of skin

Simply put, when a scratch or crack occurs in paints and coatings, a rupture/tears occurs at the microscopic level in the polymeric chain, which is the building blocks of them. Basically, what Self-Healing / Repairing Paints and Coatings do – in an autonomic or semi-autonomic way – is to repair these ruptures / tears using various technologies and mechanisms.

Industry 4.0 & The Paint/Coating Industry: Autonomous & Semi-Autonomous Repairing Paints & Coatings

In these days we entered the age of industry 4.0, Just like the new generation of autonomous vehicles, self-healing or self-repair from the paints and coatings may be expected in a autonomous way, i.E. Without any intervention or in a semi-autonomous way i.E. With a warning from the outside (temperature changes, heat, UV, IR radiation and pressure changes, etc.)

Such paints / coatings can heal and restore surface scratches and mesoscopic damages (eg micro-cracks and cavities). In doing so, they follow a two-stage path:

1. Fill the gap,

2. Heal / Repair the damaged area.

Figure 3: Two-step self-healing/repair process of paints/ coatings

Different types of self-healing/repairing paints and coatings have different technologies. These differences lead to some differences in the 2-stage self-healing process and will be summarized in the following section of the article, which is the Main Types paragraph.

Brief History

Some type of a lime mortar in ancient Roman times was reported to be reported as the oldest self-healing material by historians. In our modern times, although several articles, papers, and presentations have been published after mid 80’s worldwide, it was the 21st century that the first successful

Self-Healing / Self-Repair paints and coatings were produced in the laboratories of technical universities located at mainly USA, Canada, Europe and Australia. After years following 2010, these paints and coatings have found commercial use in various industries.Following paragraph summarizes the most popular fileds/sectors that the ever-increasing studies are carried out and commercial start-ups are established.

Which Fields/Sectors ?

Although self-repairing paints / coatings often show up in the automotive and oem sectors (especially removing paint scratches on metallic or plastic surfaces on cars), it is a known fact as a result of the current studies from different countries in the world that it can be also be used in smart phones, aerospace, defense and military equipment, industrial structural steel surfaces or even textile (see reference section) products.

2. Main Types

We can review the production methods of Self-Healing / Self Repair paints&coatings in 5 main types:

I. Microencapsulation

II. Heat-activated Thermoplastic Polymers

III. Micro-vascular network

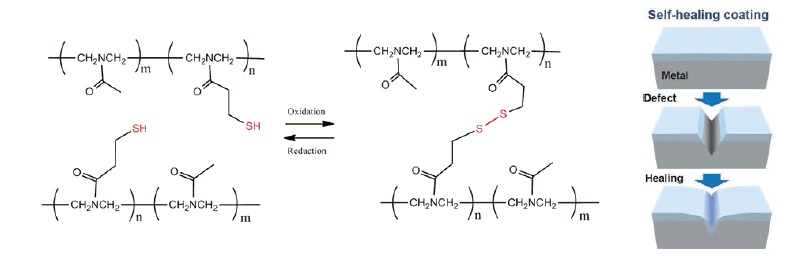

IV. Reversible chemical reactions

V. Hollow-fiber approach

However in the production of self-repairing paints / coatings, Micro-encapsulation and Heat-activated Thermoplastic Polymers are shown as prominent methods. Now let’s take a closer look at these two technologies:

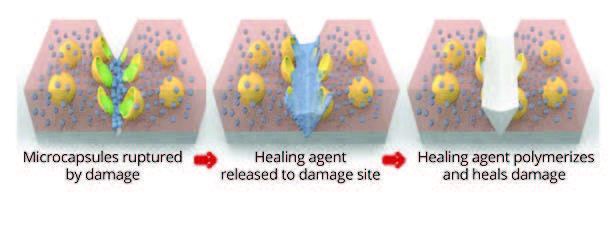

Microencapsulation

Self-Healing / Self Repair Agent Chemicals micro or even nano scale capsules are embedded inside in these types of paint and coatings.

These capsules serve as a kind of pocket in paint or coating; when an external stimuli (such as impact, scratching, tearing) happens, these capsules open up and release adhesive-like healing chemicals & agents to its surroundings.

Subsequently, the external catalyst reacts with the chemicals to form a copolymer that is larger and more robust by volume. In this way, repairing scratches / tears / punctures in that area heals the paint and coating.

Of course, all these reactions take place on a scale that cannot be seen by our eyes, in microscopic or even nano scale. (The relationship of this technology with nanotechnology will be explained in the next section.)

Figure 4: Micro-encapsulation- based Self-Healing/Self- Repair Paints and Coatings and the simple operation mechanism

Heat-Activated Thermoplastic Polymers

Self-healing / repairing paints and coatings of this type are divided into 2 subclasses:

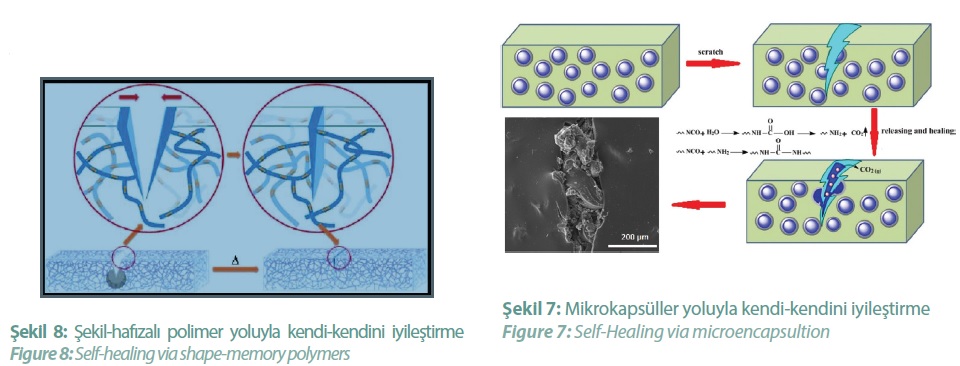

1. Shape Memory Polymers-SMPs

2. Reversible Polymers

1. Shape-Memory Polymers SMPs

Many of us use Shape-Memory materials frequently in our daily lives, but we really do not notice. For example, our glasses made of Nitonol (Nickel-Titanium), you may have witnessed that it is returning to its former form / shape no matter how much twisted or bend!

Generally, Shape- Memory Polymers work in a much more complex (and extremely interesting) manner. However, we will not go into these details1. What is important here is that such Shape- Memory Polymers are inherently flexible and require a heat or energy source to be able to return to its initial undamaged state.

For example, many automotive manufacturers and suppliers that produce paints for these manufacturers use the paints with this technology in Clear-Coat, which is the last layer of the paint system on the vehicle, and after scratching the paint, these scratches are healed with a simple heat transmitter.

Figure 5: Self-healing / repairing of the paint by applying heat to the scratched paint on the vehicle

2. Reversible Polymers

Polymers with thermoreversible chemistry,such as furan and maleimide functional groups, are used in this type of self-healing paints / coatings.

These reversible polymers can be returned to their original Un-Damaged state by means of special reversible chemical reactions such as Diels-Alder (DA), retro-Diels-Alder (RDA) with energy that can generate heat or heat to be applied to the surface after a damage.

The most important feature of these polymers is that the ends of their polymeric structures are very active; In case polymers are damaged with a mechanical damage coming form outside, they have the potential to attact each other to revert theirselves into original forms like magnets!

3. Correlation With Nanotechnology

Nanotechnology, which is the science, engineering and technology, dealing with nanometers measuring one billionth of a meter (1 / 1,000,000,000 meters), is revolutionising every aspect of our lives from from pharmaceutical industry to construction.

Especifically for self-healing / repairing paints and coatings produced by microcapsulation, the use of nanotechnology is mandatory!

Because, standart paints and coatings can be transformed into Self-Healing / Self-Repair paints and coating by the use of nano scale capsules that contains special healing chemicals. Besides, nanotechnology is also extensively used in the production of the above-mentioned shape-memory polymers.

4. Problems ve Drawbacks

The most common problems and drawbacks associated with these technological paints and coatings, of which the main types have been examined, can be summarized in 4 main items below:

I. Most microcapsules are vulnerable to the natural corrosion process of metals such as corrosion; can only repair defects caused by mechanical damage. These paints / coatings cannot detect electrochemical processes such as corrosion in advance and take precautions accordingly.

II. Since the capsules used during the microencapsulation method are very small (nanometer size, they can cause weakness in the paint chemical structure if they are larger), the healing agents / chemicals they can carry are limited.

Therefore, most of the time, these capsules are able to repair & repair only once or a few times times when they cause damage in the same location. (Their healing powers are extremely limited.)

III. During the microencapsulation method, the catalyst and curing agent chemicals required for curing often need to be stored separately and then thoroughly mixed into the paint.

Since it is not known where the damage will occur, if these two different materials are not mixed homogeneously enough, they may not have a healing effect since they cannot be close enough to each other.

IV. Healing chemical agents are extremely unstable; they can react with water and oxygen immediately. Therefore, shelf life is very short and storage conditions need to ve carefully monitored.

5.Trends and Recent Advances

In order to eliminate the aforementioned problems and drawbacks, studies are going on in many universities and research centers around the world.

For example, scientists at the BATTELLE Memorial Institute research center are working on a onecomponent intelligent particle that can predict and improve the formation of corrosion.

(Battelle Smart Corrosion Detector ® bead) These beads are spheres of 30 to 50 microns in diameter and appear to be whitish powder in bulk. Thus, giving early warning signals of corrosion in the metal surfaces, selfimprovement / repair process is expected to begin.

Figure 9: BATELLE Smart Corrosion Detector Beads

It is also possible to develop paints and coatings that react to external stimuli targeting bacteria and microbes by microencapsulation technique.

Once Microbes and Bakteria detected, it is aimed that toxic chemicals inside microcapsule are released onto them. As an example of a trigger mechanism, a specific protein in the cell walls of bacteria can be used as stimulus and it is a well-known fact in the literature.

Another popular approach in recent years is the production studies of Hybrid Self- Repairing Paints / Coatings using the 2 or more technological methods together described above in the main types.

For examples, one of the topics studied is producing dual action (or even triple action) self-healing / self repair paints having microencapsulation and reversible chemical reactions and/or other technologies mentioned above. Although this technology can be applied more easily in polymer structures that form the backbone of paints and coatings, studies are being carried out in different countries around the world to develop innovative solutions for metal, ceramic, cement and even asphalt materials. You can read more about this in the following article2.

6.Conclusion

As a result of the industrial and technological developments in the 21st century, innovations are constantly entering our lives. Self-Healing / Repairing Paints and Coatings is one of the innovative innovations that come into our lives due to industrial and technological developments in the 21st century.

The aim of scientists, researchers, research academics, and industrial R&D center experts in this field is, in fact by mimicking the Self-Healing/Self-Repair mechanisms of living organisms like us human-beings.

Hence, more durable innovative paints and coatings can be applied onto the surfaces and thus the service life of the substrates they protect will be gradually increased.

This innovative technology, which is still taking baby steps, will be able to produce advanced types with higher performance and less drawbacks by taking the vital functions of living organisms, also known as Biomimimetics.In our 21st and 22nd century worlds surrounded by technologies getting increasingly smarter, the concept of

Self-Healing / Self-Repairing Paints / Coatings is a constantly evolving technology, and it is an indisputable fact that we will hear about these materials more and more frequently in the future!

PCS. Tolga Dıraz – Kimya Mühendisi / Chemical Engineer – Koruyucu Boyalar&Kaplamalar Uzmanı / Protective Coating Specialist – TUCSA TK-4 Yüzey Koruma Komitesi Başkanı – TUCSA TK-4 Surface Protection Committee Chair