Two Component Acrylic Resins and Coating Applications

Resins are used extensively in the paint and coating industry, particularly as a protective layer against corrosion on the surfaces of metal, concrete, and wood.

Since 1996, our company, a producer of alkyd, saturated polyester, epoxy hardener, polyaspartic, and acrylic resin, has supplied various resin types to the paint and coating industry.

Among these resins, acrylic resins are offered in two different types as thermoplastic and

thermoset.

Thermoplastic resins are high molecular weight polymers that soften with heat, take the shape of the surface to which they are applied, and form a layer by evaporation of the solvent rather than by internal chemical reaction.

Thermoset resins, on the other hand, are developed by functional monomers that react

with each other or with the functional group of a crosslinker to form a cross-linked film when exposed to heat or moisture.

After crosslinking they provide films with good resistance to organic solvents, moisture and UV radiation. Acrylic monomers are polymerized using certain catalysts and initiators to create acrylic resins.

The monomer ratios, dosing duration, dosing rate, catalyst type, quantity, and temperature are the main variables influencing product quality in the manufacturing of acrylic resin.

Uses and Properties of Some Two-Component Acrylic Resins

We produce thermoplastic resins, which are used especially for coating metal surfaces and as road marking paint. On the other hand, due to its high yellowing resistance, high chemical resistance, high hardness and high impact resistance, thermosetting resins are

increasingly used in industrial paint systems, marine paints and varnishes, furniture polishes and car repair systems.

Thermoset acrylic resins that we produce in accordance with national and international standards have hydroxyl values of IZELCRYL 18B50 1,8% OH, IZELCRYL 26X60 2,6% OH and IZELCRYL 42B70 4,2% OH and are used to obtain cross-linked coatings by reacting

with isocyanates.

According on the resin’s %OH value, the quantity of isocyanate is determined. Due

to the quick yellowing and curing, the use of aromatic hardeners is not advised for acrylic two-component resins.

In systems created with aromatic hardener, mechanical qualities (such as yellowing, hardness, drying time, and pot life) would change negatively. A hydroxyl functional acrylic resin called IZELCRYL 18B50 with 1,8 OH% was created to be used in two component

systems when curing with polyisocyanate.

Industrial paint systems, furniture varnish, and vehicle repair paints all often employ our IZELCRYL 18B50 1,8 OH% thermosetting acrylic resin.

The product is favored in the market because of its broad range of applications, quick drying time, and high hardness, resistance to yellowing, strong adhesion, and minimal need for isocyanates.

Solvents selected for IZELCRYL 18B50 1,8 %OH based paints and varnishes should not contain water and should not contain groups that react with isocyanates.

IZELCRYL 26X60 2,6 %OH resin is a thermoset acrylic copolymer with high heat and corrosion resistance, 60% solids, and 2,6% hydroxyl group. IZELCRYL 26X60 2,6 %OH is used in industrial painting systems, furniture varnish and auto repair primer and topcoat

paints.

Our IZELCRYL 26X60 2,6 %OH resin, which is used with isocyanate, is preferred because of its many superior properties such as high adhesion strength, fast drying, wide application area and resistance to corrosion.

IZELCRYL 42B70 4,2% OH is a polyisocyanatecured hydroxyl functional acrylic resin developed for use in two component systems. IZELCRYL 42B70 4,2% OH acrylic resin is 70% solid and has 4,2 hydroxyl functional groups.

It is frequently employed in paint systems that need extended drying times. Due to its

chemical resistance, high and corrosion resistance, this acrylic resin, which has a high UV yellowing resistance, is also one of the reasons for preference.

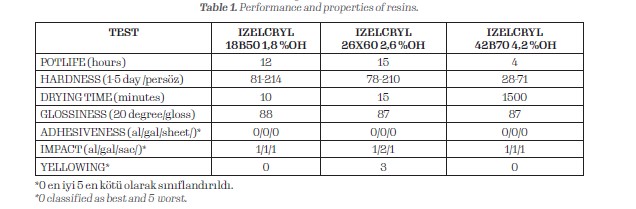

It is typically used in wood painting systems, marina varnish systems, industrial paint systems, and paint systems for car maintenance. In Table 1, the performance and

properties of the resins are given in detail.

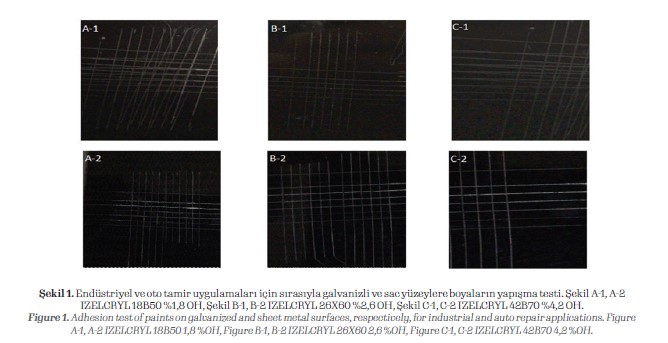

The adhesion performance of paints made from our resins to galvanized and sheet metal surfaces is given in Figure 1. When looking at Figure 1, it is seen that the adhesion of our thermoset acrylic resins does not reach the cross cut band.

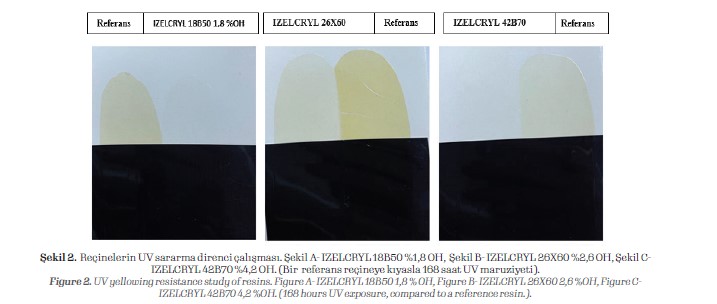

Our resins, which were turned into a thin film on a 60 micron thick zebra card, were kept in the UV cabinet for 168 hours and their yellowing was examined. UV yellowing test results are given in Figure 2.

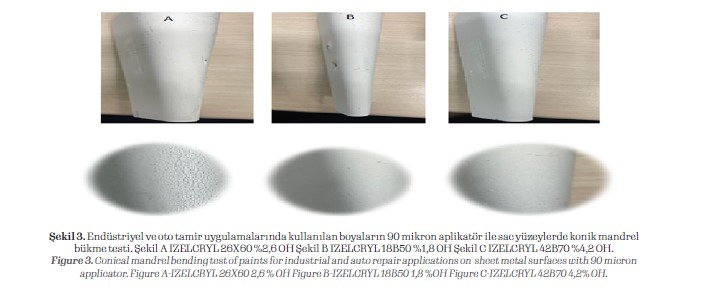

Our resins, which are also used in industrial and auto repair paint systems, have stretching properties. When looking at the paints after the bending test in Figure 3, cracking or breakage of the paints was examined.

When we look at figures 1, 2 and 3, our thermoset acrylic two-component resins are preferred when used in industrial and auto repair paints, due to their strong adhesion,

absence of cracks after bending, impact resistance, yellowing resistance and high gloss.

Dr. Cemil Dizman

R&D Manager

İzel Kimya

Levent Babayiğit

R&D Researcher

İzel Kimya