Low-fat Spreads

Can You Add 80% Water into 10% Fat and Stabilize? Our Answer Is: Yes!

In recent years, it has been observed in Türkiye that producers and consumers demand for “less fat” products have increased both in terms of health and economical reasons.

Low-fat spreads are really difficult to produce because the product tends to be unstable due to phase separations.

As a result of Palsgaard’s long years of experience, Palsgaard Denmark has achieved to produce “low fat spread” in its pilot plant with taking into considerations of below regulatory and consumer demands;

• Containing 10% total fat,

• Does not contain hydrogenated oil,

• Hydrogenated emulsifier is not used,

• Non-allergic,

• Non-GMO,

• “Low-fat margarines” that do not contain Trans Fat.

Emulsifiers are substances that can support and stabilize the dispersion of one material to another immiscible material. Food emulsifiers are amphiphilic and thus support and stabilize the emulsion dispersion.

Margarine is a Water-in-Oil Emulsion

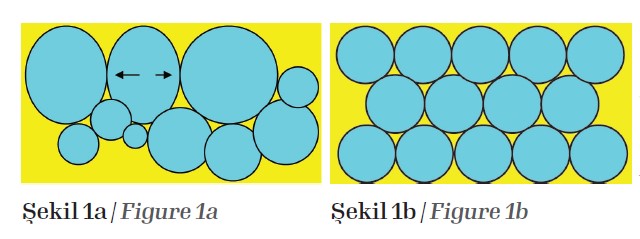

If the water droplets have exactly the same size as shown in Figure 1a; theoretically it is difficult to reduce the fat content below 25.4%.

Using Palsgaard emulsifiers as a solution; Taking advantage of the synergistic benefits of Palsgaard® DMG 0298 and Palsgaard PGPR 4175 emulsifiers, water droplets of different sizes are formed.

As shown in Figure 1b, the desired emulsion is much more compacted thanks to Palsgaard solutions.

While reducing the fat ratio in margarine, the oil phase must spread to more water droplets, so the total oil percentage and the liquid oil content must be higher than the other oil phases.

If you use more solid fat than necessary in low fat product recipe, the product will loose its smoothness and become brittle. Likewise, you should avoid using too much Palm Stearin.

According to the palm oil usage rate, the product will have a much more fragile structure during and after production. We recommend our Palsgaard® DMG 0298 and Palsgaard® PGPR 4175 emulsifiers to prevent fat separation in your “low-fat margarine” and to achieve

the right mouth feel and texture.

Palsgaard® DMG 0298; is a mono-diglyceride (E471) but atypical compared to many other mono-diglycerides because the fatty acid combination is mainly based on oleic acids.

Unsaturated fatty acids offer better emulsification and emulsion stability for reduced

and low oil dispersions compared to standard monodiglycerides. Palsgaard® PGPR 4175; It is made of polyglycerol polyricinolate (E476) but is more polymerized than normal

PGPR types. PGPR in low-fat spreads; It is extremely important in coating water droplets, oil crystals and increasing viscosity in low oil emulsions.

It is not possible to make very low fat spread without PGPR. Therefore, Palsgaard® PGPR 4175 is essential to stabilize the 10% low oil spread as it helps prevent fluctuations in

the production process and reduces the amount of rejected product.

Palsgaard® PGPR 4175 is both taste and odor neutral. We recommend our Palsgaard® 6118 product to stabilize the oil phase. Palsgaard® 6118; It is based on non-hydrogenated vegetable oils and is particularly suitable for applications where we do not want to use hydrogenated products.

The oil separation inhibiting effect of Palsgaard® 6118 is effective in products containing a high amount of oil, such as the oil phase in low-fat spreads. By keeping the oil in the product like a net, it greatly reduces the risk of oil overflowing.

In addition to the strength and quality of the emulsifiers used and the importance of the

inputs of the recipe, the production process is of great importance to reach a successful product in this difficult journey.

The manufacturing process is just as important as the emulsifiers and the types of oil used.Your process for producing a 10% fat product is the opposite of your production process used for making a 40% fat product.

In other words, we recommend that you do not use the same production process you used

when making your 40% fat product If too much mechanical processing is involved in the production of low-fat margarines, the emulsion itself is highly viscous.

When making 30-40% low-fat margarine emulsions, mixers that work well need to be designed for more viscous emulsions. Otherwise, “dead” areas will form in the emulsion tank.

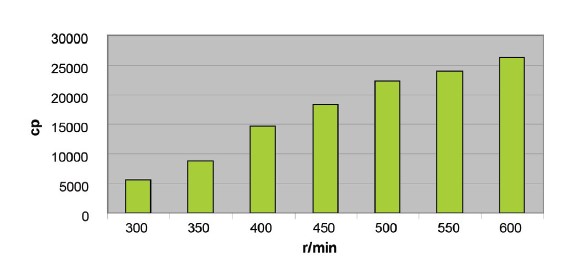

Slow mixing is essential to prevent the build-up of high-viscosity emulsions. As seen in Table 1, it is observed that in a pre-emulsifying unit, the viscosity can be increased up to 5 times in line with doubling the mixing speed.

In addition to the quality, strength and effect of the emulsifiers used; It is necessary to pay attention to many tricks until the temperature in the tanks, removal of the pin machine

from the production process, high production capacity, regulation of packaging temperatures and storage conditions.

Crystallization of the product is also important in low-fat margarines, but as in high-fat products, phases of oil crystals do not dominate the product.

In high-fat products, factors such as the melting points of the crystals affect the mouth feel, while in low-fat products, strong emulsifier systems affect the whole product quality in addition to the mouth feel and eating quality.

In addition to our knowledge and experience in challenging and complicated final product recipes, we make use of Palsgaard’s strong, high quality and reliable emulsifiers, making the final products that are said to be impossible to come true.

With Palsgaard products, we are happy to support you in finding innovative solutions without sacrificing your quality. The modern food emulsifier was invented by the founder of Palsgaard, Einar Viggo Schou, in 1917.

Since then, we have never stopped developing and improving our products, and its

part of our DNA to keep developing yours. Bringing together your unique challenges and our drive for perfection is the recipe for a successful collaboration, and for great products that consumers love.

We also bring together the know-how of a century with deep sense of responsibility for future generations. That’s why all our production sites are CO2-neutral and why we go to great lenghts to live up to the relevant UN Sustainable Development Goals. Learn more about our heritage and values at our website.

Ebru Önügören

Pastry, Bakery and Oil Technical Sales and Application Manager

Palsgaard Türkiye