Analytical Characterization of Paint Raw Materials and Microbial

Pigments

Introduction

Paints are used for decoration purposes as well as to protect different surfaces. The desired demand meet depends on the characteristics of the raw material used in paint production and these play an important role in the environmental impact, quality, and safety of the paint.

Depending on where the paint is to be applied, water or solvent-based products are used

to facilitate the application process. While the paint dries on the applied surface, the solvent evaporates and the resins (solvent or water-based) are cured, thus allowing the paint to establish a physical and chemical bond with the surface.

Pigments, which are generally preferred for decoration purposes, are also used as fillers or additives. TiO2, the basic white pigment, has excellent coverage. Carbon black is widely used as a black pigment. Other pigments are iron oxide and cadmium sulfide for red color, metallic salts in yellow and orange colors, iron blue for blue color, and chromium yellow for green color are the most preferred compounds.

Fillers such as calcium carbonate, aluminum silicate, talc, and kaolin provide flexibility

and strength properties to the paint besides reducing the cost. Additives facilitate both the production and application of the paint to the surface (Figure 1).

Analytical Characterization of Paint Raw Materials

The foams formed during the production and application of the paint are removed by using antifoam agents, as they make dispersion difficult, increase the cost and cause a surface defect in paint production.

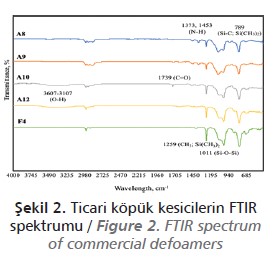

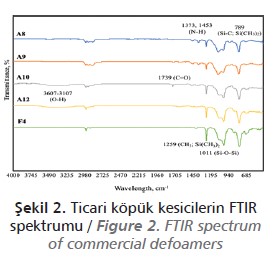

With the help of a graduated cylinder, the effect of the antifoam agent can be determined

in a simple test setup. At the same time, the functional groups in the structure of defoamers can be detected by the FTIR spectroscopy technique (Figure 2) [1].

In cases where the defoamer is missing or excessive, defects called fish eye, pinhole, orange peel, and crater are observed. These defects are more prominently visible under

a stereo microscope. Dispersant substances provide a homogeneous distribution of pigments and fillers in the paint and are used together with wetting agents (surfactants).

The high wetting rates of pigments and fillers increase the color intensity of the pigments to the same extent. The wetting properties of dispersants and fillers are determined with the help of rheology and viscosity tests.

Furthermore, with the help of the Zeta Potentiometer and Particle Size Measurement Device (Mastersizer), the effect of the wetting agent on the wetting rate of the pigment and filler can be observed depending on the pH of the paint.

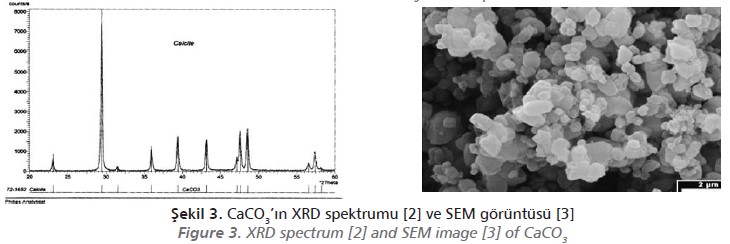

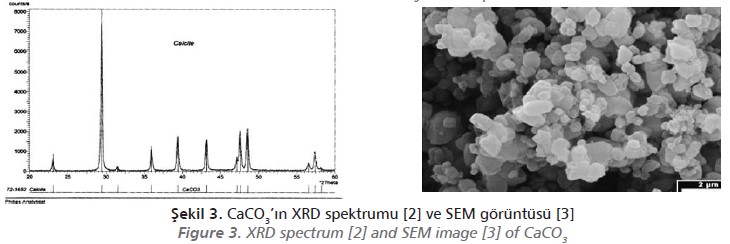

With the help of FTIR spectrometer, the effect of each substance can be determined by examining the functional structures formed between pigments and resins, solvents, additives, and fillers. The impurities in the structures of inorganic pigments and fillers (such as calcium carbonate, and talc) are determined by XRD and XRF analysis techniques.

SEM and EDX analysis are used to determine both the surface appearance and elemental content of pigments and substances (Figure 3). The ability of fillers to absorb the solvent and other liquid additives is studied using the BET surface area measurement device.

Chromatography group devices such as GC, GC-MS, HPLC, and LC-MS/MS, are widely preferred for the determination of organic contents in the structure of solvents and resins. After the paint application and drying processes are completed, color and gloss tests are performed. To determine its effectiveness against environmental conditions and UV

radiation, air conditioning and UV resistance tests are carried out.

At the same time, corrosion and strength tests should be applied depending on the surface on which the paint is applied. Under SEM analysis and stereo microscope, cracks and yellowing that may occur on the painted surface are observed. Paints intended for use in different areas for special purposes are those that provide heat insulation, absorb sound and exhibit antibacterial properties.

Paints that provide heat insulation are preferred especially in very hot and cold regions

where energy efficiency is important [4]. Sound absorbing paints have started to be developed for the noise pollution problem, which is among the important problems of our age.

Microbial Pigments

Because some of the chemical compounds used in synthetic paints are toxic, mutagenic, carcinogenic, and allergenic, there is growing interest in natural compounds and pigments that are nontoxic, safe, and easily obtained from living organisms [5].

Natural pigments are obtained from plant, animal, or microbial sources. Obtaining pigments from animal sources is costly and difficult. On the other hand, the acquisition of pigments from plant sources is easy and cheap but has disadvantages such as changing climatic conditions and is not suitable for production at all times of the year.

Bacterial pigments, on the other hand, have great advantages because, unlike plant

pigments, their production does not show seasonal variations, they can be easily produced under laboratory conditions, high yields can be obtained, and the microorganisms from which they are obtained grow rapidly [6].

At the same time, they are biodegradable and environmentally friendly which are important for a sustainable world. Pigments produced by microorganisms are not necessary for their basic vital activities but are secondary metabolites that make the microorganism resistant to various biological agents and stress conditions.

In addition to their benefits to microorganisms, many pigments have been shown to have antimicrobial properties. In this way, it has been reported that the pigment used as a color additive can provide antimicrobial properties to the manufactured product.

The color range of pigments obtained from microorganisms is quite broad, and the place of some bacterial pigments in the Munsell color system has been determined [7]. To date, a large number of pigment-producing bacteria have been identified, and their pigment production processes have been optimized (Table 1).

Pigments derived from microorganisms are used in many sectors in developed countries. They are used as colorants in paints, cosmetics, inks, and papers. In the textile industry, the red pigment prodigiosin derived from Serratia marcescens is used to dye acrylic, polyester, silk, and cotton fabrics [8].

Similarly, the purple violacein pigment produced by Janthinobacterium lividum can be used in the production of antimicrobial polyamide fabrics [9]. In addition, they are used in the food industry both as a colorant and for antimicrobial properties [7].

As the demand for natural pigments increased due to the toxicity problems of synthetic pigments, many pigmentproducing bacteria were identified, the culture conditions and fermentation medium were optimized, and large-scale production of pigments was realized.

Fermentation and Production Processes

Compared with the evolving global market needs, the production volume of microbial pigments is still low today compared to synthetic paints. There is better scope to increase the overall production volume to meet market demands by applying various biotechnological tools.

Commercial pigment production is possible with the combination of genetic engineering and fermentation technologies. In this context, gene, protein, and metabolism engineering to increase the biosynthetic performance of the microorganism, genome shuffling, and fermentation strategies to bring production to the industrial level play a vital role in the maximum and environmentally friendly production of microbial pigments with low cost and high stability [7].

Optimization of fermentation conditions and development of economical downstream processes can enable the cost-effective production of microbial pigments. Media

optimization includes changes in fermentation conditions such as temperature, pH, incubation time, nutrient sources, aeration, and agitation speed to select the conditions that provide the best yields.

The response surface methodology (RSM) technique has many advantages over conventional methods used for environment optimization and requires less experimentation to obtain an optimum combination of all the variable factors studied.

Artificial neural networks (ANNs) are another technique that can be used to study the

effect of fermentation conditions as well as optimization for microbial pigment production. Optimization of fermentation conditions thus requires less time and effort leading to a reduced overall cost [10].

References

[1] A. Hassan, K. Jumbri, A. Ramli, N. Borhan, Physio-Chemical Analysis of Amide and Amine Poly(dimethylsiloxane)-Modified Defoamer for Efficient Oil-Water Separation, ACS Omega. 6 (2021).

https://doi.org/10.1021/acsomega.1c00350. [2] S. Sahebian, S.M. Zebarjad, S.A. Sajjadi, Z. Sherafat, A. Lazzeri, Effect of both uncoated and coated calcium carbonate on fracture toughness of HDPE/CaCO3 nanocomposites, J Appl Polym Sci. 104 (2007). https://doi.org/10.1002/app.25644. [3] P. Wedin, J.A. Lewis, L. Bergström, Soluble organic additive effects on stress development during drying of calcium carbonate suspensions, J Colloid Interface Sci. 290 (2005). https://doi.org/10.1016/j.jcis.2005.04.020. [4] Ş. Balbay, Düşük Maliyet ve Yüksek Enerji Tasarrufuna Sahip Termal Boya Üretimi, Konya Journal of Engineering Sciences. 8 (2020) 693–705. https://doi.org/10.36306/konjes.643725. [5] F.M. Drumond Chequer, G.A.R. de Oliveira, E.R. Anastacio Ferraz, J. Carvalho, M.V. Boldrin Zanoni, D.P. de Oliveir, Textile Dyes: Dyeing Process and Environmental Impact, in: Eco-Friendly Textile Dyeing and Finishing, 2013. https://doi.org/10.5772/53659. [6] M. Aman Mohammadi, H. Ahangari, S. Mousazadeh, S.M. Hosseini, L. Dufossé, Microbial pigments as an alternative to synthetic dyes and food additives: a brief review of recent studies, Bioprocess Biosyst Eng. 45 (2022).

https://doi.org/10.1007/s00449-021-02621-8. [7] C.K. Venil, L. Dufossé, P. Renuka Devi, Bacterial Pigments: Sustainable Compounds With Market Potential for Pharma and Food Industry, Front Sustain Food Syst. 4 (2020). https://doi.org/10.3389/fsufs.2020.00100. [8] X. Liu, Y. Wang, S. Sun, C. Zhu, W. Xu, Y. Park, H. Zhou, Mutant breeding of serratia marcescens strain for enhancing prodigiosin production and application to textiles, Prep Biochem Biotechnol. 43 (2013). https://doi.org/10.1080/10826068.2012.721850. [9] M. Kanelli, M. Mandic, M. Kalakona, S. Vasilakos, D. Kekos, J. Nikodinovic-Runic, E. Topakas, Microbial production of violacein and process optimization for dyeing polyamide fabrics with acquired antimicrobial properties, Front Microbiol. 9 (2018).

https://doi.org/10.3389/fmicb.2018.01495. [10] B. Rana, M. Bhattacharyya, B. Patni, M. Arya, G.K. Joshi, The Realm of Microbial Pigments in the Food Color Market, Front Sustain Food Syst. 5 (2021). https://doi.org/10.3389/fsufs.2021.603892.

Assoc. Prof. Dr. Şenay Balbay - Bilecik Şeyh Edebali University

Central Research Laboratory Application and Research Center (BARUM)

Asst. Prof. Dr. Ardahan Eski - Bilecik Şeyh Edebali University

Central Research Laboratory Application and Research Center (BARUM)

Assoc. Prof. Dr. Rafig Gurbanov - Bilecik Şeyh Edebali University

Central Research Laboratory Application and Research Center (BARUM)

In cases where the defoamer is missing or excessive, defects called fish eye, pinhole, orange peel, and crater are observed. These defects are more prominently visible under

a stereo microscope. Dispersant substances provide a homogeneous distribution of pigments and fillers in the paint and are used together with wetting agents (surfactants).

The high wetting rates of pigments and fillers increase the color intensity of the pigments to the same extent. The wetting properties of dispersants and fillers are determined with the help of rheology and viscosity tests.

Furthermore, with the help of the Zeta Potentiometer and Particle Size Measurement Device (Mastersizer), the effect of the wetting agent on the wetting rate of the pigment and filler can be observed depending on the pH of the paint.

With the help of FTIR spectrometer, the effect of each substance can be determined by examining the functional structures formed between pigments and resins, solvents, additives, and fillers. The impurities in the structures of inorganic pigments and fillers (such as calcium carbonate, and talc) are determined by XRD and XRF analysis techniques.

In cases where the defoamer is missing or excessive, defects called fish eye, pinhole, orange peel, and crater are observed. These defects are more prominently visible under

a stereo microscope. Dispersant substances provide a homogeneous distribution of pigments and fillers in the paint and are used together with wetting agents (surfactants).

The high wetting rates of pigments and fillers increase the color intensity of the pigments to the same extent. The wetting properties of dispersants and fillers are determined with the help of rheology and viscosity tests.

Furthermore, with the help of the Zeta Potentiometer and Particle Size Measurement Device (Mastersizer), the effect of the wetting agent on the wetting rate of the pigment and filler can be observed depending on the pH of the paint.

With the help of FTIR spectrometer, the effect of each substance can be determined by examining the functional structures formed between pigments and resins, solvents, additives, and fillers. The impurities in the structures of inorganic pigments and fillers (such as calcium carbonate, and talc) are determined by XRD and XRF analysis techniques.

SEM and EDX analysis are used to determine both the surface appearance and elemental content of pigments and substances (Figure 3). The ability of fillers to absorb the solvent and other liquid additives is studied using the BET surface area measurement device.

Chromatography group devices such as GC, GC-MS, HPLC, and LC-MS/MS, are widely preferred for the determination of organic contents in the structure of solvents and resins. After the paint application and drying processes are completed, color and gloss tests are performed. To determine its effectiveness against environmental conditions and UV

radiation, air conditioning and UV resistance tests are carried out.

At the same time, corrosion and strength tests should be applied depending on the surface on which the paint is applied. Under SEM analysis and stereo microscope, cracks and yellowing that may occur on the painted surface are observed. Paints intended for use in different areas for special purposes are those that provide heat insulation, absorb sound and exhibit antibacterial properties.

Paints that provide heat insulation are preferred especially in very hot and cold regions

where energy efficiency is important [4]. Sound absorbing paints have started to be developed for the noise pollution problem, which is among the important problems of our age.

SEM and EDX analysis are used to determine both the surface appearance and elemental content of pigments and substances (Figure 3). The ability of fillers to absorb the solvent and other liquid additives is studied using the BET surface area measurement device.

Chromatography group devices such as GC, GC-MS, HPLC, and LC-MS/MS, are widely preferred for the determination of organic contents in the structure of solvents and resins. After the paint application and drying processes are completed, color and gloss tests are performed. To determine its effectiveness against environmental conditions and UV

radiation, air conditioning and UV resistance tests are carried out.

At the same time, corrosion and strength tests should be applied depending on the surface on which the paint is applied. Under SEM analysis and stereo microscope, cracks and yellowing that may occur on the painted surface are observed. Paints intended for use in different areas for special purposes are those that provide heat insulation, absorb sound and exhibit antibacterial properties.

Paints that provide heat insulation are preferred especially in very hot and cold regions

where energy efficiency is important [4]. Sound absorbing paints have started to be developed for the noise pollution problem, which is among the important problems of our age.

Pigments derived from microorganisms are used in many sectors in developed countries. They are used as colorants in paints, cosmetics, inks, and papers. In the textile industry, the red pigment prodigiosin derived from Serratia marcescens is used to dye acrylic, polyester, silk, and cotton fabrics [8].

Similarly, the purple violacein pigment produced by Janthinobacterium lividum can be used in the production of antimicrobial polyamide fabrics [9]. In addition, they are used in the food industry both as a colorant and for antimicrobial properties [7].

As the demand for natural pigments increased due to the toxicity problems of synthetic pigments, many pigmentproducing bacteria were identified, the culture conditions and fermentation medium were optimized, and large-scale production of pigments was realized.

Pigments derived from microorganisms are used in many sectors in developed countries. They are used as colorants in paints, cosmetics, inks, and papers. In the textile industry, the red pigment prodigiosin derived from Serratia marcescens is used to dye acrylic, polyester, silk, and cotton fabrics [8].

Similarly, the purple violacein pigment produced by Janthinobacterium lividum can be used in the production of antimicrobial polyamide fabrics [9]. In addition, they are used in the food industry both as a colorant and for antimicrobial properties [7].

As the demand for natural pigments increased due to the toxicity problems of synthetic pigments, many pigmentproducing bacteria were identified, the culture conditions and fermentation medium were optimized, and large-scale production of pigments was realized.