Emülzer Signature in Green Roof Insulation

Because of the increasing land prices and developments in construction technology, people want to have more time in their living spaces with indispensable green of nature. They want to get away from the stressful environment of the city and add freshness to their lives. Landscape design is made accordingly in newly constructed buildings. Upon the demands of the end consumers, the contractor companies give more importance to green reinforcement areas in their site projects. It is demanded to arrange the areas above the terraces, flat roofs, architectural protrusions or underground car parks that are not currently used as spaces, but also as usable green spaces.

Landscape arrangements and applications have created a serious sector. Landscape architecture combines concrete and green. The application details are long, but the

results are extremely successful. The excess of these applications will bring some advantages to human health and the world we live in. These are:

– The green areas lost during the construction of the buildings are gained,

– There will be a decrease in the amount of water to be drained due to the collection of rain water and its return to the ecosystem, which helps to reduce the load of the city sewer system,

– Reduction in noise, dust and smoke levels,

– Since the insulations will be protected from ultraviolet rays, a longer-lasting insulation is provided,

– By giving oxygen to the environment, environmental pollution is reduced,

– Sociological and psychological positive results are obtained,

– The value of the building increases.

In the garden roof insulation, what will be the last step should be decided from the beginning. The purpose of the space to be used should be determined in advance.

Accordingly, a suitable system should be developed. Planning, designing is free, but implementation is paid. Questions such as the following must be answered beforehand.

• Is there afforestation?

• Will it be left as grass?

• Will there be sports etc. activities on the grass?

• What are the types of plants to be greened?

• How will the tree and plant care be done?

• What will be the type of soil, what will be the thickness of the soil to be laid? Also, will fertilizer etc. be thrown away?

• Is it clear that the plants will be irrigated every other day, every other day, by dripping, serpentines or other methods?

• What is the flow rate of irrigation water?

During the terrace garden application, every detail should be done carefully and no stage should be given up. One of the most neglected details is unfortunately waterproofing, which seems simple. If waterproofing is not applied with the right product, the right detail and the right workmanship, the life of the building will be shortened. Corrosion in reinforced concrete structures does not only occur in the foundation, it can start wherever the concrete comes into contact with water. Garden terrace insulation, in short, ends with surface cleaning, preparation, primer, application of plant root resistant product, protection of insulation, drainage, soil laying and planting.

If the insulation applied when the roots of the plants develop and grow is not resistant to the plant roots, the insulation layers exposed to the piercing effect of the roots will be damaged, no matter how much water you have protected your floor. Root secretions consist of large and small molecule organic compounds secreted by the roots.

Large molecule organic compounds form mucilages and ectoenzymes, while small molecule organic compounds form amino acids including sugars, organic acids, phenolic compounds and phytosiderophores. For example, it is seen that the concrete is damaged in flowerpots and flower pots made of concrete.

Finishing the application without giving importance to waterproofing by saying “the soil holds water anyway, there is no need for insulation” means accepting that water starts to flow from the roof of the house if it is the roof, and from the ceiling if it is the car park. Complaints of end consumers and initiation of litigation processes will be a plus. What has been done is dismantled, the waterproofing that was not done at first or was not taken care of is done again. Temporary solutions made using unsuitable materials will give the same result because the initial cost will be high, and in this case the cost will be more than

planned. For this reason, planning should be done by deciding what kind of application and arrangement will be made in the first place.

The materials to be used should be chosen accordingly. An English proverb says, “I’m not

rich enough to use cheap”. Indeed, sometimes the costs we avoid in the first place can cost us dearly later on. The suffering, distress, and stress are also worth it.

The solutions realized by architects and engineers in the project should be reflected in practice. Emülzer has developed Plus Anti Root, a one-component, root-proof, modified bitumen and solvent-based waterproofing product for green roofs. Not every bitumen or bitumen cement based product is resistant to plant roots. Special chemical additives such as biocide used in the waterproofing material must be used during production. These chemicals prevent and stop the progression of plant root tips. The chemical additives used do not harm the plant and prevent the progression of the roots.

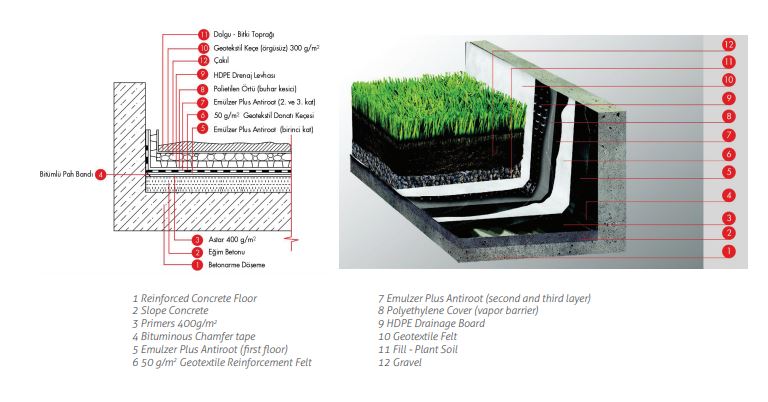

The system that should be applied in the insulation of such areas is briefly as follows:

Surface cleaning and preparation is done on concrete. After the cracks in the concrete with cracks and depressions are opened, they are filled with non-shrinking repair mortars or epoxy-based anchor repair mortar. Emilkote, anionic bitumen emulsion material, is applied to the surface with a consumption of 0,400kg/m². All horizontal and vertical corner turns are angled with elastic Emulzer Bituminous Chamfer Tape. After the primer coat dries, one

component, cold applied, modified bitumen based, super elastic and elastomeric root impermeable liquid membrane Emulzer Plus Anti-Root should be applied. It should be applied with a bitumen brush or airless pump with a consumption of 3.00 kg/m² in at least three coats and wait one day between coats. While the first layer is fresh, 50-80 gr/m² geotextile felt is laid on it. The felt, which works as a carrier between the insulation layers, will prevent the cracks that may occur on the floor from passing to the insulation layer. After the insulation layers are completed, the drainage board with 110 gr/m² geotextile felt is laid with the bubbles and the felt facing upwards before the landfill. The insulation layer and the drainage board are turned up to the greening upper level at the parapet edges and fixed to the parapet with pressure profiles. Thus, overflowing water is prevented from entering under the insulation from the sides.

Cem Ercan

Civil Engineer M.Sc.

Project and Technical Sales Manager

Emülzer Asfaltevi Tecrit Maddeleri San. ve Tic. Ltd. Şti.