Our Fireproof Resin and Gelcoat Group for Railway Systems

Polres Polyester was established in 2003 in Gebze Plastikçiler Organized Industrial Zone to produce polyester resin, gelcoat,pigment paste and vinyl ester.

In polyester resin group, our company produces Casting Type, Hand Lay-up and Spray up, Pultrusion, Continuous Laminating, Hot Press SMC and BMC, DCPD Resins, RTM and Infusion Filament Winding, Flame Retardant, Adhesive Type, Chemical Corrosion Resistant, Putty Type, Button Type, Mold Type, Breton, Polymer Concrete.

As for the gelcoat group, products include General Purpose, Performance, High Performance, Chemical Resistant, Sandable, Flame Retardant, Bright Topcoats, Mold Making Gelcoats and; in the pigment paste group; RAL K5, RAL K7, Pantone catalog colors.

Polres has ISO 9001:2015, ISO/IEC 27001:2017 and EN 45545-2, UL-94, BS476 part 7 certificates for its flame retardant products. POLRES exports 85% of its production. All works of Polres are customer-oriented; in this direction, it continues to work to take its place in the world market.

The need for fire retardant product groups is increasing rapidly today. These products are used in railway, highway etc. transportation vehicles, residences, electrical systems and wherever it is desired to fight fire.

According to the 2020 Fire Statistics Report of the Istanbul Fire Department, as of November 2020, 19,087 fires occurred only in Istanbul. Of these fires, 4,023 were reported as residential fires, 169 as factory fires, 6,241 as other building fires, 1,480 as vehicle fires and 7,174 as non-structural fires.

Even the figures shared above in only one province of Turkey are quite large and have caused many material and moral damages. When considered throughout the country, fire is seen as a danger that deeply affects the society due to the losses it creates.

At this point, it is vital to invest in fire protection measures. Increasing our social awareness about fire and using innovative technologies in fire response systems are among our priorities in order to be protected from fire hazards.

For example, it has been reported that at least 70 people died in the train fire in Pakistan in 2019. If the wagons of the train in this fire had been made using fire-resistant composite materials, the number of people killed and injured as a result of the fire could have been minimal.

According to the behavior of the trains and equipment on the railways to the fire, the number of people who can survive a fire that may occur increases. It has developed a new classification system for European rail fire safety requirements using the fire safety regulations for rail vehicles of the European Railway Union (UIC) and different European countries.

With this developed system, EN 45545-2 standard is sought for all products used in rail

systems projects where human health and safety are at the forefront. To comply with EN 45545-2, materials must behave in a certain way when exposed to fire; Flame retardant: EN 45545-2 compliant materials must be flame retardant so that in the event of fire, their composite materials successfully help prevent the spread of fire and provide more time for the carriages to be evacuated safely.

Low Smoke: EN 45545-2 compliant rail materials must also have low smoke emissions to help prevent smoke penetration. Ensuring that the smoke density is as low as possible is vital to allow train personnel and passengers to escape from the carriage and be rescued as quickly as possible without exposure to the dangers of smoke inhalation.

Low Toxicity: Many train parts can generate extremely dangerous toxic gas. On the other hand, special rail materials complying with EN 45545-2 are formulated to provide low toxicity properties, so train line personnel and passengers are exposed to a minimum amount of fumes.

As Polres Polyester, we have designed our products to meet this standard. We adjusted the long-term ignition, short-time flame and smoke extinguishing features of our products according to the ranges required by the standard.

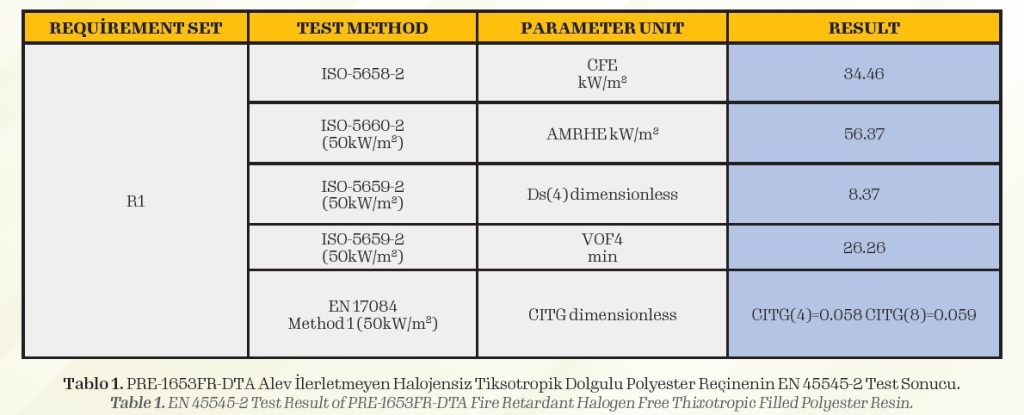

As a result of the tests carried out by an accredited institution, the results of the PRE-1653FR-DTA resin and the gelcoat made from this resin are shown according to the EN 45545-2 standard.

According to the results of Table 1, our product achieved results well above the reference intervals in terms of flame spread, flame extinction, smoke amount and toxicity. The

HL3 result, which is the highest value in this classification, was obtained for the resin and gelcoat made from this resin.

With our UL-94 V0 and BS-476 part 7 class 1 certificates, the fire resistance of the materials to be used in the residences has been documented. Table 2 and Table 3 below show the results of these resins.

Polres Polyester R&D