HYPOMER® MT 2550K – Hydroxy Acrylic Matting Resins

Introduction

HYPOMER® MT 2550K is a hydroxy acrylic based, proprietary liquid matting resin that provides excellent matting effect without the addition of any additional matting agent upon drying.

HYPOMER® MT 2550K consists of a low odour, aromatic free composition.

Dry films of the resins are characterized by excellent transparency, smoothness and tactile or touch feeling effect.

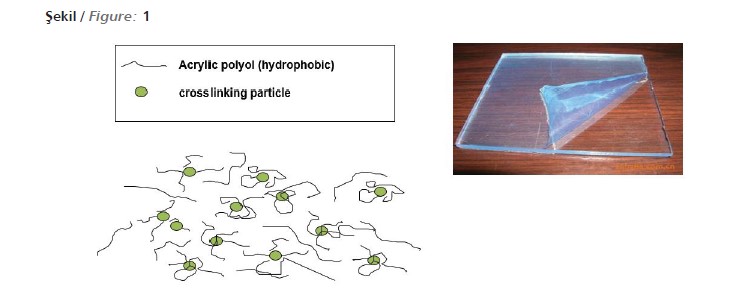

HYPOMER® MT 2550K adopts a special polymerization reaction and process that combines

non-soluble acrylic particles with a liquid resin through a bridging mechanism, as shown in Figure 1.

Through a good balance of hydrophilicity and hydrophobicity, the solid particles are uniformly dispersed and suspended in the liquid resin to form an opaque white liquid.

HYPOMER® MT 2550K has good adhesion on ABS, ABS/PC and other plastic substrates. It also has good compatibility with conventional hydroxy acrylic resins.

Consequently, resin combinations of HYPOMER® MT 2550K and other fitting OH functional crosslinking resins, e.g. acrylic, PU, etc. produce, depending on the ratio, a wide range of semi-matt to matt clear, solid color and metallic finishes with excellent performance.

Matting Theory

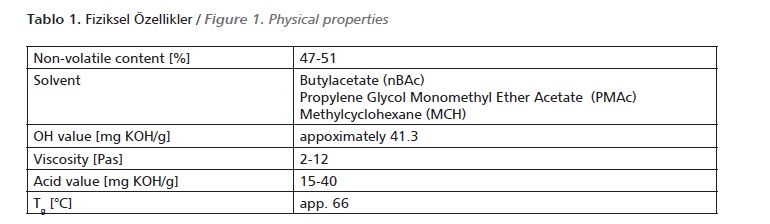

Upon coating, evaporation of solvents and subsequent crosslinking reaction of the matting resin with curing agent result in volume shrinkage and protrusions of solid particles out of the cured film.

As shown in Figure 2, the protruded particles cause light scattering on the film surface, thus resulting in the matting effect.

Unlike inorganic silica matting agents, the solid acrylic particles have a lower density, as such they are more evenly distributed in the coating film resulting in a more uniform matting effect over a wide range of dry film thickness.

Because of the organic nature of the solid particles, the cured films have better transparency and touch feeling effect.

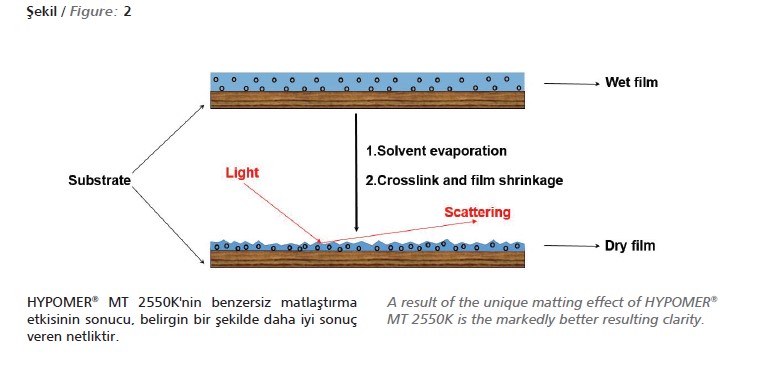

In case matt clearcoats are formulated to similar gloss levels, HYPOMER® MT 2550K

yield significantly better clarity/ transparency than conventional systems containing silica

matting agent, as shown in Figure 3.

This is evident when the coatings were applied onto PET film, as shown below.

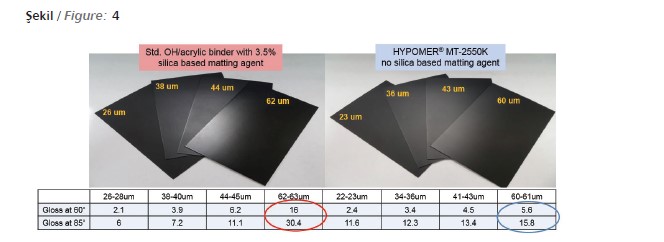

A further key advantage of HYPOMER® MT 2550K is the gloss consistency over a wide range of dry film thickness in spray application compared to the conventional matt coatings formulated with silicabased grades.

As shown in the Figure 4, the conventional system shows a markedly higher gloss level

at higher DFT due to settling of the matting agent.

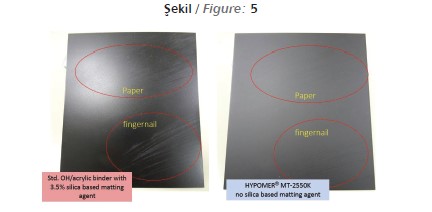

Matt coatings based on HYPOMER® MT 2550K provide superb scratch resistance. Figure 5 visualizes this effect of HYPOMER® MT 2550K compared to a conventional, silica based matt clearcoat.

As can be seen, scratch marks are only minorly visible with HYPOMER® MT 2550K whereas the conventional coating has obvious scratch marks.

This performance advantage of HYPOMER® MT 2550K translates into better polishing property than that based on conventional matte coating systems.

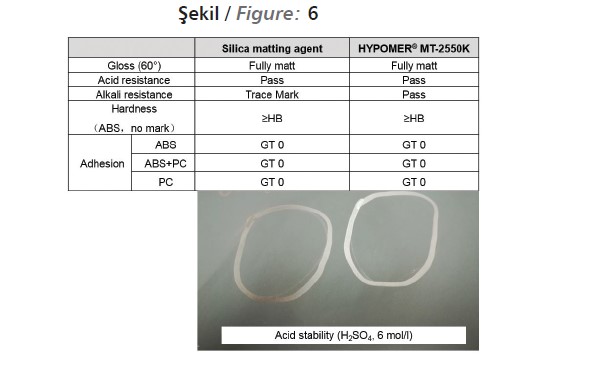

Further remarkable benefits provided by HYPOMER® MT 2550K are the chemical and scratch resistance of the resulting coating film.

As shown in Figure 6, the chemical resistance of the coating formulated wit HYPOMER® MT 2550K can be classified as excellent.

Especially the alkali stability is improved to coatings formulated with standard silica based

matting agents. In all the other test segments, no changes could be noticed.

Conclusion

HYPOMER® MT 2550K is a high-performance resin and excellent formulating tools for a unique class of nonaqueous, matt and semi-matt clear, pigmented and metallic finishes.

Matt coatings formulated with HYPOMER® MT 2550K combine excellent film transparency,

gloss consistency, scratch resistance and tactile properties and are superior to those of the conventional matte coatings based on silica matting agents.

It might be used in various industrial applications such as coatings for automotive interior parts and exterior trims, automotive refinishes, industrial and decorative coatings, plastic components, and inks.

Experimental

Tested system: non-aqueous 2c, PU coating

Gloss measured using the Byk Gardner Haze/gloss

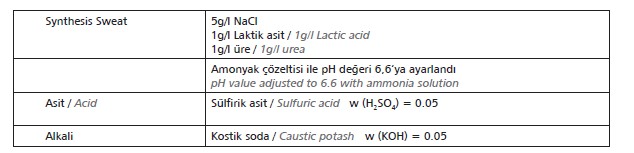

Test Procedure Chemical Resistance

• Gauze with acid, alkali, sweat, tea, coffee and water solution is put on Hypomer MT-2550K film.

• Testing time: 120 minutes

• Evaluate surface immediately.

Writer: Udo Schonhoff

Technical Sales Manager Coatings EMEIA

Elementis GmbH

Edited by: Çise Karamehmetoğlu

Sales Executive

Fuchs Kimya A.Ş.

Edited by: Fırat Pınar

Sales Executive

Fuchs Kimya A.Ş.