In this study, coffee wastes, which pose a serious threat to our environment as methane gas and increase the formation of carbon footprints, are easily obtained as a coloring natural substance to be used in the painting of buildings by recycling. Waste coffees were collected from businesses around us with the help of a certain container and after sterilization, they were dried and powdered.

Thus, by being added to the building paints, the coffee essence was added to the paint and showed a homogeneous distribution feature. As a result, the masterbachs obtained will be effective in the production of industrial paints such as construction and will support the increase of our country’s market share.

1. Introduction

Paints are defined as coatings applied for insulation and protection purposes in order to give color to any object. Paints can be applied to almost all materials. Masterbachs are used as coloring matter in paint production. The task of the masterbachs is to provide

the desired color tone easily. The main purpose is to make the desired color stay longer on the desired surface after the application.

While synthetic based materials have been used as masterbach from past to present, with an increasing demand in recent years, it is desired to produce dye coloring matter by recycling method from natural materials, especially waste materials. Sometimes it is desired to provide paint adhesion time, prevent mold and odor formation, provide heat insulation and sometimes superhydrophobic (water repellent) and sometimes superhydrophilic (water-loving) properties on the surfaces of metal, polymer and ceramic even composite materials, which have been especially emphasized in recent years.

While synthetic dyes are synthesized with chemicals, they may appear as carcinogenic substances. Azo dyes, carcinogenic and allergenic aromatic amines can endanger the environment and human health. Most synthetic dyes are toxic and mutagenic. They consist of a mixture of masterbatch, pigments, additives and polymer materials (carrier resin). It

is used to color plastics and paints for applications such as packaging, construction, consumer goods, automotive, textile, agriculture and packaging.

Color masterbatch, white and black masterbatch, additive and filled masterbatch refer to different types of masterbatches depending on properties and functionality. Polymer-based masterbatch is preferred to differentiate different plastics and paints. The world Masterbatch market is expected to grow from USD 11.0 billion in 2018 to USD 14.0 billion by 2023 [1]. An ever-increasing market share and an ever-increasing need for masterbach production processes and the originality of the raw materials used. Various initiatives have been made from waste materials and natural plants for the increasing demand, adding color properties to construction chemicals. Many companies continue their initiatives at various levels and create new product ranges.

There are products that are used for masterbach purposes by obtaining activated charcoal from waste materials. The aim here is to both create an aesthetic appearance and show absorbent properties in the area and environment where it is used or applied. Activated charcoal, as a natural cleaner, cleans the smoke and pollution in the environment. For this purpose, it provides functional use. However, although the production procedure seems easy, the underlying R&D studies and production investments may be higher. It is seen that there is a serious demand for technical and waste materials, which can be an easier process and economical, but can make a high contribution in terms of performance, in the construction sector and other color applicators.

For this purpose, we have obtained natural dye coloring matter with waste coffee, which increases the carbon footprint for our environment and releases methane gas. Coffee production will lose 50% of its production capacity until 2050, especially in the African region. This means that since the production will be less, the arrival price of the coffee will

be higher. In addition, 2-5 kg of daily coffee waste is generated in a branch of a coffee business as a waste product at the rate of 98%. In its hundred branches, 200-500 kg of waste is generated per day. When we look at the month and the year, we are faced with a

serious waste threat.

Therefore, we have carried out our work to raise awareness and a more sensitive understanding of consumption, and we can create application areas that can provide high performance by making wastes valuable. In our study, masterbach was obtained as the building paint color agent, and it is obvious that the application area will expand when

the building is first mentioned and then industrial paints, and when it is supported by R&D studies and PUR, concrete outputs will be easily obtained in the field.

2. Material and Method Material

Waste coffees are collected from coffee businesses around us.

Method

Obtaining Masterbach from Waste Coffee

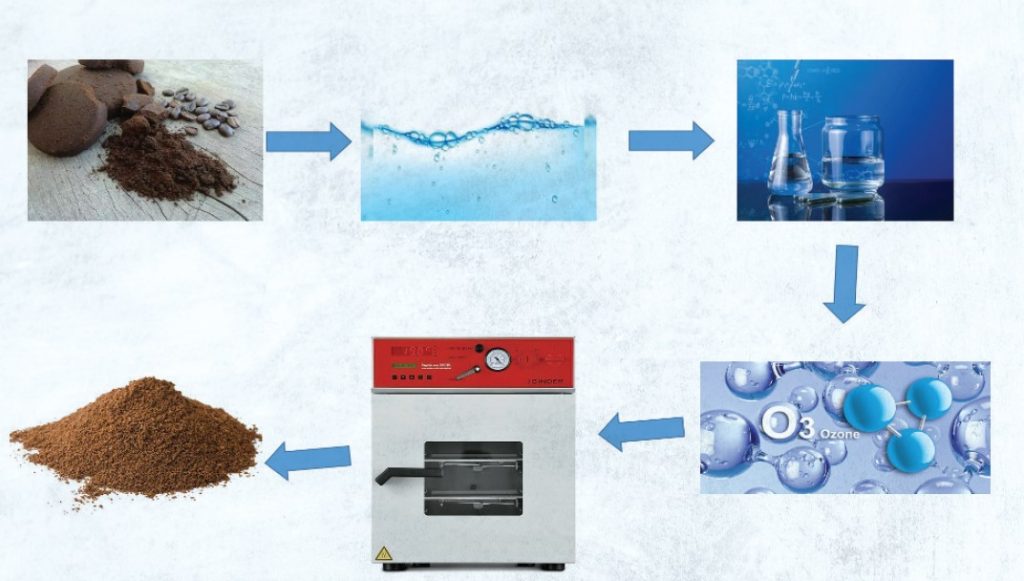

2 kg of waste coffee was collected at the end of the day with the help of a container from the coffee businesses in our area. The collected coffees were washed twice in tap water and after washing, washing was continued with pure water for half an hour. After the process, the waste product was sterilized with ozone gas and left to dry in a vacuum oven. The

dried coffees were reduced to a powder size of 40- 63 micrometers, with the help of a ceramic mortar and ball grinder, and the appropriate powder size after sieving. Thus, the active substance to be added to the paints as a masterbach color additive was obtained. Figure 2.1 shows the method of obtaining masterbach from waste coffee.

3. Results and Discussion

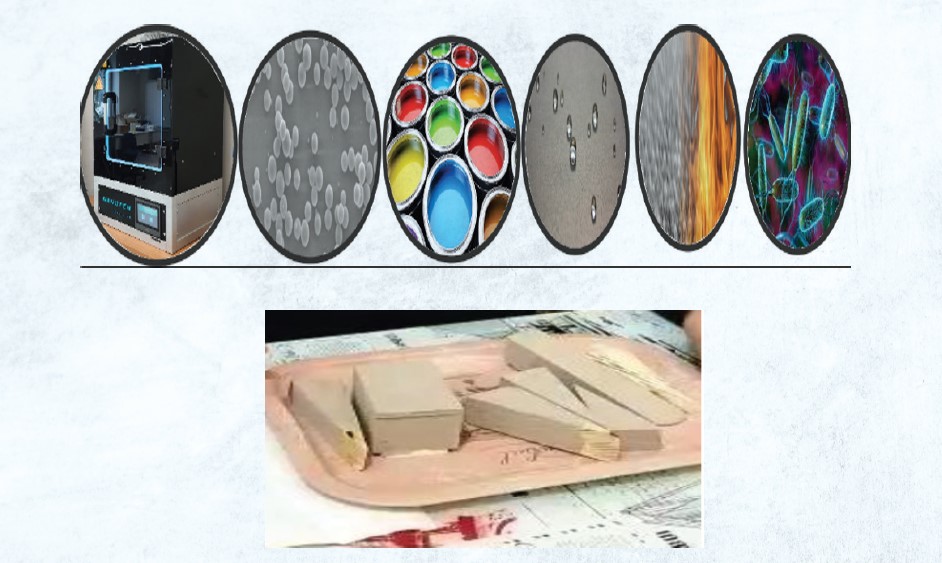

Color was given by adding to the paint,and burning and water behavior tests were carried out by applying on wood and foam. While the paint applied area did not burn, the wood and foam burned. In addition, while wood and foam love water in repelling water, the pores formed in our paint are tight and smaller, so water drops escape without contact. When applied to the wall, especially on the exterior, since the water will not come into contact with it, it can be stored and provide potential returns that can appeal to irrigation and other purposes for other purposes. Masterbach applied wood and foam surfaces and our test

processes are shown in Figure 3.1.

4. Conclusions

In our study, masterbach as a dye color material to be successfully added to the dyes was carried out with an easy and inexpensive method. As a masterbach, the active ingredient was obtained from waste coffee and by adding it to the paint, painting on wood and foam was achieved. It has been determined that it has successfully passed the combustion and water repellent test. We have obtained a patent application for the product we have developed. Our product, and then after application product ranges and construction

chemicals, will be able to appeal to industrial paints and all application areas as a color material. Our next attempt is to dye by supplying a mixture of one or more herbs as a natural dye. Thus, we want our companies to gain awareness of the performance in

this area.

References

[1] https://www.budingroup.com/tr/konsantre-boyalar/masterbatch-kuresel-pazar-tahmini-2023/

Erdi Buluş

Lecturer

stanbul Arel University

ArelPOTKAM

Gülseren Sakarya Buluş

Expert

Bahçeşehir University Management Engineering Ph.D. Student