Wear Subject and Anti-Wear Surface Treatments

Since wear is a surface-related issue, it mostly occurs on the outer surfaces of the parts. Wear controls the life and performance of many moving mechanical parts in industrial parts and designs. In most industrial applications, significant financial losses, occurs due to accelerated wear (adhesive, abrasive, corrosive, fatigue, corrosion, erosion, cavitation) of various mechanical components.

Various methods of surface treatment and coating are employed to protect the material from wear related degradation. To minimize the effects of mechanical wear, coating and surface engineering solutions that extend the life of the part or product continue to be developed. At this point, the choice of coating material and method plays a critical role. It is necessary to determine the coating selection, coating thickness and coating method suitable for the substrate type, piece size and surface properties. The properties expected from the coating should be evaluated depending on the working environment, working conditions and loads.

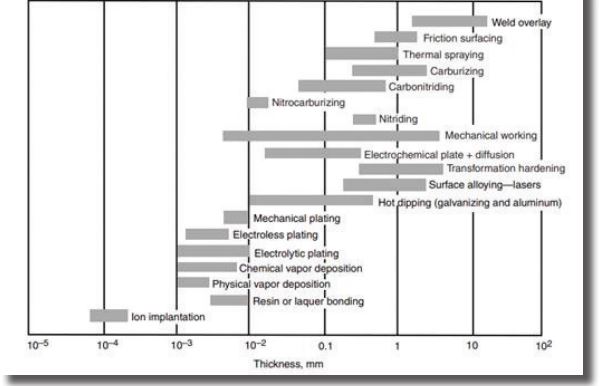

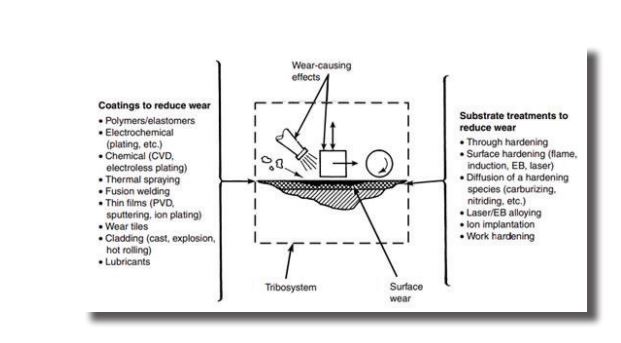

In Figure 1, the approximate thickness of the various surface engineering processes is shown comparatively. Thick wear-resistant coatings can be obtained by welding-based hardfacing and thermal spray methods. Thin film coatings can be produced in mono or multi-layers under 5 microns. Figure 2 shows the surface engineering processes used to prevent wear.

Selecting an appropriate technology to produce a certain combination of surface characteristics is a very complex process. It involves systematic correlation of specifications with attainable surface properties. Usually, the selection surface treatment process includes economic and ecological evaluations. Surface technologies are gaining importance as integral parts of manufacturing chains. While surface treatments can generally be applied separately today, It can be integrated into post-process and process chains. Basically, 16 criteria are used in the selection of surface coatings and surface treatments:

(1) Operating temperature,

(2) Operating environment,

(3) Contact and loading types,

(4) Substrate material,

(5) Counterface material,

(6) T/C and substrate bond strength,

(7) Processing economics,

(8) Surface T/C hardness,

(9) Processing temperature,

(10) Component size,

(11) T/C depth,

(12) T/C uniformity,

(13) Component shape,

(14) T/C surface finish,

(15) Pre-processing,

(16) Post-processing,

The five solution stages are: (1) operating constraints, (2) processing constraints, (3) geometrical constraints, (4) topographical constraints, (5) economic constraints.

General Conclusion

Wear-resistant metallic, ceramic or composite-based coatings can be applied with different methods, with semi-automatic or fully automatic systems, depending on the geometry

and number of parts. Performance characteristics are compared depending on operating conditions and process cost. The coating selection and application method of the users

are among the most important criteria. The reliability and life expectancy of the part depends on the quality of the coating and the success of the application.

References

• J.R. Davis, Surface Engineering for Corrosion and Wear Resistance, ASM International 2001.

• C.M. Cotell and J.A. Sprague, Preface, Surface Engineering, Vol 5, ASM Handbook, ASM International, 1994.

• K.G. Budinski, Surface Engineering for Wear Resistance, PrenticeHall, Inc., 1988.

• W. Tillmann, E. Vogli, Selecting Surface-treatment Technologies, Materials Science, 2006.

Assoc. Prof. Dr. Ekrem Altuncu

TÜYİDER (Surface Treatments Association of Turkey) Scientific and Advisory Board Member

Sakarya University of Applied Sciences

Material and Production Technologies Application and Research Center – SUMAR Manager