For decades, facade paints have had two important functions: They lend an attractive appearance and offer protection from the effects of weathering. Therefore, producers of premium facade paints have worked hard to optimize these two properties in their products.

Silicone resin paints are now state-of- the-art options for exterior applications. These paints contain emulsified silicone resins in addition to a primary binder, which is generally a styrene-acrylate dispersion. Such paints have excellent weathering resistance and a long service life.

Over the last few years, however, customer requirements have increased. The color selection needs to be larger. The facade needs to be slower to soil than before and all these performance characteristics need to be achieved by environmentally compatible means.

Researchers at Evonik have now developed a new silicone resin that meets these increased requirements: TEGO® Phobe 1659. As an added bonus, it can be used in significantly lower concentrations than the established alternatives, thus saving costs.

High Water-Vapor Diffusion, Low Water Absorption

Facade paints must promote good diffusion of water vapor so that moisture coming from the interior does not accumulate in the brickwork.

Under some circumstances, this moisture may lead to a build-up of pressure that can cause coatings that are not permeable to water- vapor to burst.

High water vapor diffusion is achieved by the supercritical pigment volume concentration at which the binder, due to its low quantity, does not fill all the interstitial spaces of the filler and pigment particles, thus allowing a network of micropores to be formed.

These pores create a surface prone to attack by penetrating water, such as rain. Hydrophilic pores absorb water strongly. This absorption strength can be illustrated by modeling a pore as a vertical cylindrical capillary. The capillary rise h of the water is given by the capillary equation:

where σ is the surface tension and ρ is the density of the water, θ is the contact angle of the water on the capillary surface, g is the gravitational constant, and r is the pore radius.

For a hydrophilic pore with a contact angle of 0°C and a radius of 100 nm, the capillary rise is 157 meters, so the water column would be taller than Cologne Cathedral. This effect needs to be minimized, and this is most effectively achieved through the surface chemistry of the capillary.

When the contact angle θ > 90°C, the water sinks instead of rising: Under the same conditions (but with a contact angle of 140°C), the water sinks by as much as 100 meters.

The pore surfaces must therefore be made hydrophobic — without heavily impacting the microporous structure that makes watervapor diffusion possible. In practice, this is achieved by the addition of silicone resin emulsions.

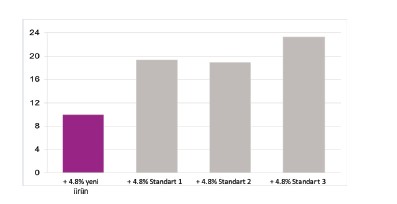

Evonik’s researchers have conducted trials to quantify the hydrophobic effect of the new silicone resin. They painted mineral substrates with a paint previously treated with TEGO® Phobe 1659 and immersed the substrates in water for 24 hours.

The water absorption during this period was found to be significantly lower than for formulations using commercially available reference products.

The water absorption coefficient w24 was below 0.1 kg/(m²*h½) and 60-80% lower at a silicone resin concentration of 4.8%. Even at a concentration of only 2.0%, TEGO® Phobe 1659 retains this excellent w24 value — something never before achieved. (Graphic 1)

The w24 value of a coating generally decreases upon additional exposure to water because the surface-active components that enable penetration of water into the pore network are washed out of the coating. In practice, it is best if the lowest possible w24 value is obtained after only a few exposures to water. This property is termed “early water resistance”. TEGO® Phobe 1659 achieves its optimum w24 after the second exposure to water. For the reference products, the results after the first two passes were inadequate and comparable performance was not achieved until further exposure to water was had. For users, this means that paints formulated with TEGO® Phobe 1659 show good water resistance directly after drying – not only after a few heavy showers.

Transmission Electron Microscopy

To further investigate the distribution of the silicone resin in the paint, the developers obtained electron micrographs. By means of spatially resolved energy dispersive x-ray spectroscopy (EDX), they also determined the local distribution of the elements.

To allow for identification of the silicone resin, no silicone-containing fillers or pigments (such as quartz or silica) were used; calcium carbonate and titanium dioxide were used exclusively. A commercially available styrene-acrylate dispersion was used as primary binder.

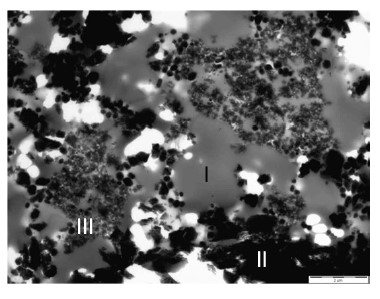

Paint layers with 2.0% and 4.8% silicone resin — based on TEGO® Phobe 1659 and on a commercially available standard — were removed from the substrate and embedded in an epoxy resin under vacuum. The researchers then prepared 180 nm thick sections and investigated these. Figure 1 shows a representative result.

Figure 1. Electron transmission micrograph of a silicone resin

paint containing 2.0% TEGO® Phobe 1659. Magnification: x 2000.

Three areas can be distinguished, denoted in the image by I, II,

and III.

The paint contains 2.0% TEGO® Phobe 1659 and, as expected, has a porous, non- homogeneous structure. Micrographs of paint layers with another silicone resin at a higher concentration are almost identical at first glance.

Three regions can be distinguished, which are denoted in the image by I, II, and III. Region I is pale in color, amorphous, and homogeneous. EDX shows almost exclusively carbon (C) and oxygen (O), and this appears to be pure binder. Region II consists of dark, homogeneous structures of high electron density.

EDX shows here titanium (Ti) and calcium (Ca) as well as other elements, therefore this must be pigment or filler. Finally, for the non-homogeneous region III, also with fairly high electron density, EDX shows silicone (Si) in addition to carbon (C) and oxygen (O). This appears to be silicone resin.

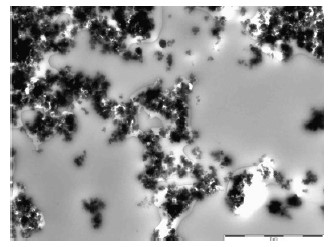

The distribution of silicone resin in the film is of crucial importance for its effectiveness. Upon more detailed examination, striking differences are seen here between TEGO® Phobe 1659 and the market standard. Figures 2A and 2B show higher-resolution micrographs; silicone resin can be seen in addition to the primary binder..

Figure 2A. Electron transmission micrograph of a silicone

resin paint with 4.8% of a commercially available standard.

Magnification: x 4000. The silicone resin (dark colored) is partly

encapsulated by the primary binder.

Figure 2B. Electron transmission micrograph of a silicone resin

paint containing 4.8% TEGO® Phobe 1659. Magnification: x

4000. Primary binder (light) and silicone resin (dark) are spatially

separated from each other.

Figure A shows that the commercially available silicone resin is encapsulated to a large extent by the primary binder, undoubtedly to the detriment of its efficacy.

On the other hand, Figure B shows that with TEGO® Phobe 1659, there is almost complete separation between silicone resin and binder, so the silicone resin is fully effective. This microscopic phase separation is likely due to the molecular structure of the silicone resin and the choice of emulsifiers used.

A second difference between the two silicone resins is observed in the EDX spectra of the pigments.

Graphic 2. EDX of pigment particles. When TEGO® Phobe

1659 is used, silicone (Si) is found in addition to titanium

(Ti), which is not the case for the commercially available

standard.

The EDX spectrum of the commercially available standard shows some calcium and titanium but no silicone. Alternatively, the EDX spectrum of TEGO® Phobe 1659 shows both titanium and silicone, indicating that the pigment particles have been coated with a silicone resin film.

The high affinity of TEGO® Phobe 1659 for pigments and fillers — in addition to the aforementioned phase separation — explains its particularly high efficacy at low concentrations.

Lower Dirt Pick-Up

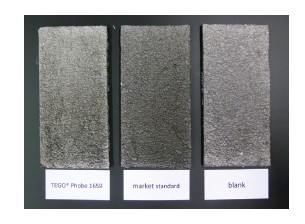

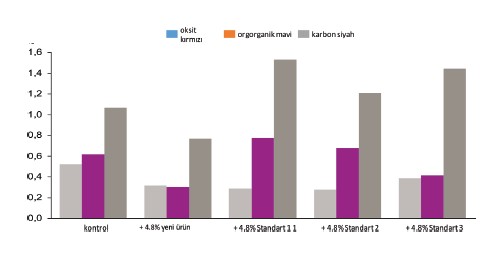

an accelerated soiling test in the laboratory that simulates outdoor weathering, the researchers also found that facades with formulations based on TEGO® Phobe 1659 pick up dirt only half as much as the market standard.

Figure 3. Tendency to soiling. Formulations based on TEGO® Phobe 1659 show L

values that are lower by up to 30% in the soiling test.

For this test, Evonik used a special machine. Water is treated with a dirt mixture consisting of tar, carbon black, and Japanese Norm Dirt. Test plates coated with silicone resin paints are soiled with this water in the machine. The machine then heats the plates to 50°C and washes them with clean water.

This cycle is repeated several times over a defined period. After the simulated soiling, the formulation with the new silicone resin structure showed L values (which indicate the degree of soiling) up to 30% lower than formulations with other silicone resins.

Formulation with Organic Pigments

The high pigment affinity of the new silicone resin is also important for pigment concentrate uptake. Tests have shown that color paste uptake for paints formulated with silicone resin is better than pigment concentrate uptake for paints without silicone resin.

This means that formulators can save on pigment concentrate while still obtaining the same tinting strength.

The particular strength of TEGO® Phobe 1659 lies in its versatility: It can also be used with pigment concentrates based on organic pigments and therefore allows a far wider choice of colors than what has been previously possible with most silicone resins.

Graphic 4. Rub-out values after addition of 5%

pigment concentrate

Advantages in Processing And Storage

TEGO® Phobe 1659 is suitable for liquid plasters as well as facade paints. It offers additional advantages in processability because the usual flow limit on the market is currently significantly higher.

Tests have shown that, particularly after storage, the flow limit of plasters formulated with the new silicone resin is only about one-third of that for plasters using the reference products, regardless of storage time.

Formulations with the new silicone resin structure have a very favorable rheological profile, which simplifies application for the processor. Moreover, the homogeneous distribution of the silicone resin results in a more uniform structure in the plaster.

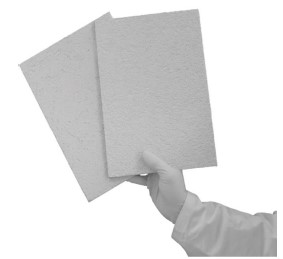

Figure 4. Surface structure of plasters. Formulations based on TEGO® Phobe

1659 show a more uniform surface structure with the same filler package.

This enhances its visual appearance and also prevents the formation of fairly large grooves, which would strongly promote water absorption. The viscosity remains significantly lower than for other commercially available products, even if the paint is exposed to a temperature of 50°C over a fairly long period.

This facilitates application after storage. Tests showed no effect on viscosity even after 256 days of storage — in contrast to reference products and to paints without additive, where the viscosity increased by a factor of 50.

Analyses of the storage modulus G‘support this observation: After only one week of storage, this value was significantly lower than that of the reference product and of the formulation without hydrophobing agent.

After 256 days of storage, the storage modulus G‘for TEGO® Phobe 1659 had doubled, while the standard product and the formulation without additive showed an 8-fold increase

Graphic 5. Storage modulus G‘as a function of time. With TEGO® Phobe 1659, G‘is lower by one third at the onset and increases only slightly over time. Without silicone resin, or with the market standard, G‘increases strongly over time.

While this data doesn’t indicate that the standard product compromises the formulation’s stability, it does confirm that TEGO® Phobe 1659 provides a more stable product over time. This can be attributed to TEGO® Phobe 1659’s high affinity for pigments and fillers and it ultimately why formulations containing TEGO® Phobe 1659 have a signification longer service life.

Environmentally Compatible for Broad Market Access

Because all these functions are obtained with even thin paint layers, the user’s material requirements are reduced.

And the environment also benefits because, since the beginning, the developers have chosen the raw materials so that the finished formulation can satisfy high certification demands and easily surmount the regulatory obstacles in various countries.

Possible certificates include Blue Angel, the Nordic Ecolabel, and the EU Ecolabel.

Technology Standard Raised

To sum up, Evonik has launched TEGO® Phobe 1659 – a silicone resin that shows improved technical properties even at reduced concentrations. For the end customer, it offers a wider selection of colors and reduces maintenance costs.

These benefits are combined with high environmental compatibility, so that the product sets a new technology standard on the market for hydrophobing agents for facade paints and plasters.

Markus Vogel

Senior Manager Applied Technology

Architectural Coatings

Evonik Resource Efficiency GmbH

Roger Reinartz

Senior Manager Applied Technology

Leather&Paper Coatings

Evonik Resource Efficiency GmbH

Daniel Brünink

Director Global Marketing

Decorative Coating

Evonik Resource Efficiency GmbH